SCOPE

This design guide covers the minimum requirements for layout and spacing of equipment for refineries, oil and gas onshore installations and processing facilities.

The provisions laid down in this specification shall be complied with in full and any exceptions must be authorised in writing by the Owner.

In the event of any conflict between this specification and any of the applicable codes and standards, the contractor shall inform the Owner in writing and receive written clarification before proceeding with the work.

This General Engineering Specification will form part of the Purchase Order/Contract.

DEFINITIONS

Dropout Area

A designated maintenance area adjacent to elevated equipment or structures to accommodate the lowering of equipment internals, such as tower trays, by means of a davit fixed to the tower. Other applications may apply, such as catalyst loading and unloading at reactors and dehydrators.

Laydown Areas

A designated maintenance area local to rotating or other mechanical equipment where space is restricted, such as in a compressor building. For example, the casing of a compressor can be lifted and laid down in a specific area so that the compressor machinery can be inspected and maintained.

Tube (or Bundle) Pulling Area

A designated area to allow the pulling of removable tube bundles from heat exchangers and condensers. This definition also applies to the removal of furnace tubes for fired heaters.

Bunded Area (also known as a Diked Area)

A retaining area surrounding a storage tank or group of tanks sized to contain the contents of the largest tank (plus the additional cubic capacity occupied by the remaining tanks, up to the level of the bund wall) in the designated area in case of rupture of the tank wall.

Bund walls (or Dikes) are normally earth walls with sloped consolidated sides. Concrete bund walls are sometimes used for smaller storage tanks or in restricted areas.

Maximum Heat Radiation Flux Level (Heat Flux)

This is the maximum allowable heat flow emitted by a flare or a fire that may be tolerated by operating personnel and equipment.

This factor is measured in either BTU/h ft2or kW/m2(the latter is more recognised).

The maximum continuous human tolerance without protective clothing is a heat flux of 500 BTU/h ft2(1.5 kW/m2). The maximum allowable heat flux for process units is 2000 BTU/h ft2

(6 kW/m2).

Sterile Area

Area surrounding a flare stack, with controlled access (subject to "Work Permit" restrictions). Total destruction of vegetation to avoid ignition.

DESIGN

Codes and Standards

The design shall comply with this specification and the following codes and standards :

Institute of Petroleum (IP)

- Model Code of Safe Practice - Part 3 Refining Safety Code

- Model Code of Safe Practice - Part 9 Liquefied Petroleum Gas

National Fire Protection Association (NFPA)

- NFPA Standard No.30 Flammable and Combustible Liquid Code

American Petroleum Institute (API)

- PI 2510 Design and Construction of LPG Installations

American National Standards Institute (ANSI)

- ANSI B31.3 Process Piping

- ANSI A99.10 Uniform Building Code, Earthquake Regulations

Oil Insurance Association

- Publication No. 631 General Recommendations for Spacing

LP Gas Association

- LPG Codes of Practice Code of Practice No.1 Installation andMaintenance of Fixed Bulk LPG Storage:Part 1 Design and Installation

Unless specified otherwise in the Purchase Order/Contract, the current editions of the codes and standards at the time of the Order shall be used.

Area Classification

General

Area classification divides the plant into areas based on the probability of combustible materials being present in that area. Classifications shall be in accordance with General Engineering Specification.

GENERAL REQUIREMENTS

General

Process plants, units and equipment shall be arranged by the Vendor/Contractor to provide an economical facility which shall be safe and easy to operate. In order to develop a detailed layout of a refinery, petrochemical installation or an oil or gas onshore production facility, a number of studies and investigations are needed and shall be carried out, i.e. soil conditions, plant location, environmental impact, pipeline routes, public utility connections (if any), air, road or sea access. Requirements for future expansion shall be allowed for by the Vendor/Contractor.

Environmental Effects

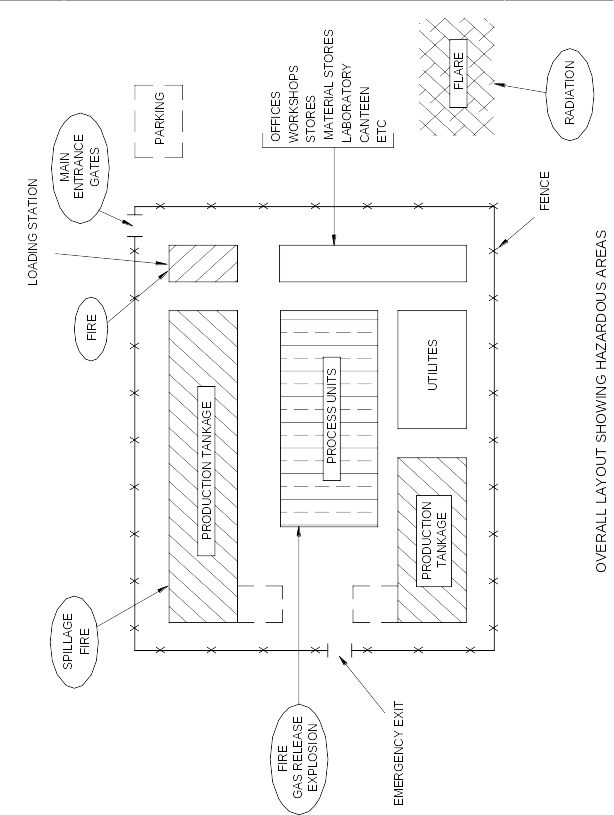

Distance from other industrial (i.e. source of ignition) and residential areas shall be considered. Installations shall not endanger the environment under normal operating or emergency conditions. These conditions shall thus determine the boundary fence limits.

Fire and Emergencies Protection

Critical emergency facilities shall be easily accessible for operators to perform emergency shutdown actions in the case of a fire or an explosion.

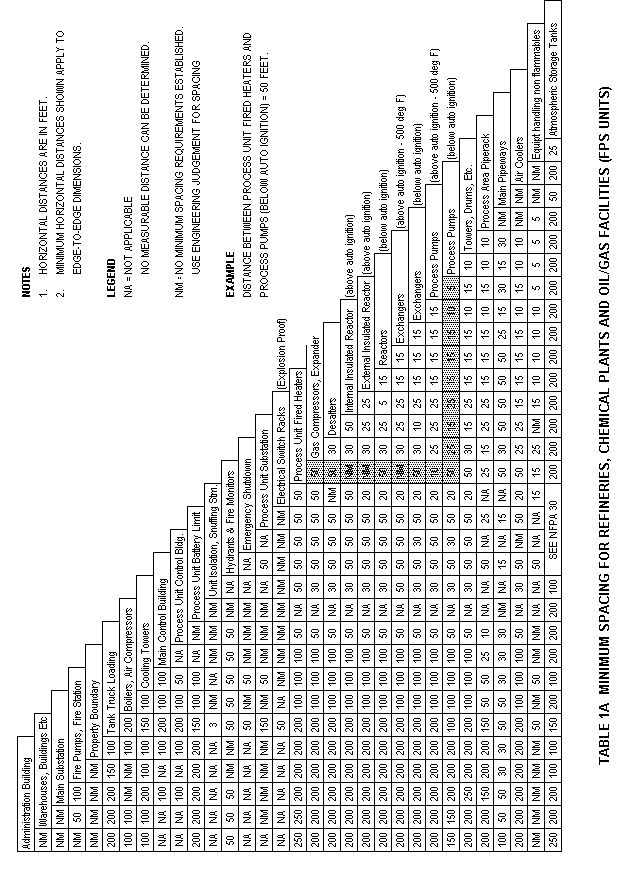

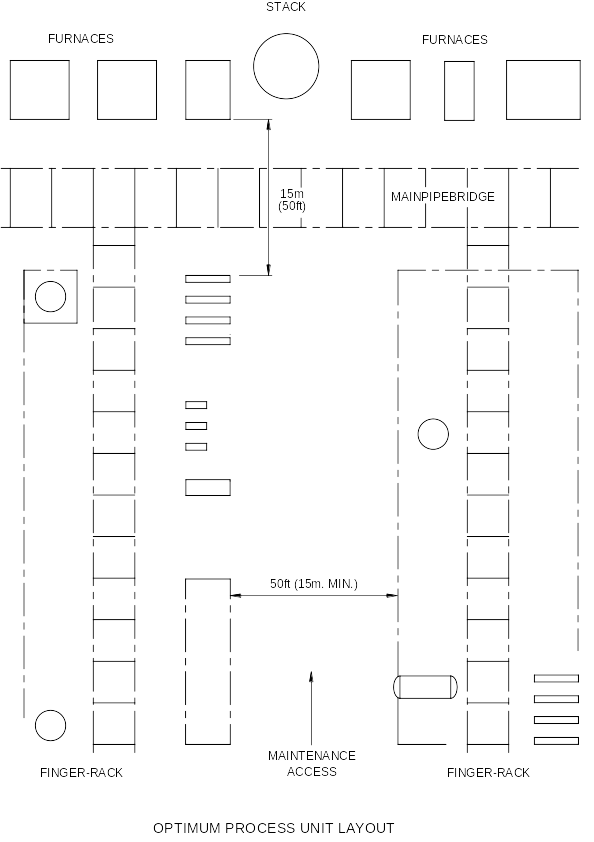

The layout should provide accessibility for fire-fighting and emergencies, and to minimise involvement to adjacent facilities in a fire (see Figure 1 for typical model). Minimum separation distances are laid down in below Tables :

Maintenance and Operation

The layout should provide easy access for plant personnel and vehicles for normal operation and maintenance of equipment.

Separation distances between units should enable maintenance to be carried out safely in one unit, with adjacent units in operation (see below Figure 2 ).

High Risk Equipment

High risk equipment (i.e. Process Unit Fired Heaters) or facilities shall be segregated (as practically possible) from less hazardous equipment (i.e. Atmospheric Storage Tanks) and operations.

Site Security

Site security shall be achieved by providing appropriate boundary fencing and gates. The level of site security shall be determined by the Owner.

Climatic Design Data

The prevailing wind direction should be determined and shown on the site plot plan and the process plot plan(s). Maximum and minimum ambient temperatures and maximum precipitation should be established.

Note: For all climatic design data i.e. earthquake zoning etc., refer to General Engineering Specification .

Site Drainage/Effluent Collection

The main collection points for rain water and effluent shall be located at the lowest elevation corner of the site to utilise the natural ground slope (preferably downwind).

Future Expansion

Future expansion shall be assessed and space allocated for known and unforeseen future requirements. Orderly expansion shall be achieved by providing space adjacent to a similar type of facility. Extensions to pipe sleepers, pipetracks, road crossings and yard piping shall be given due consideration. Care shall be taken to facilitate future expansion without any interference to existing plant on stream.

PROCESS UNITS LAYOUT

Optimum Layout

The typical process unit layout as shown in above Figure is called a `finger-layout' and is recommended for optimum economy, maintenance and operation. If there are multiple units, they should be laid out side by side with the `finger' racks at 90° to the main pipe bridge.

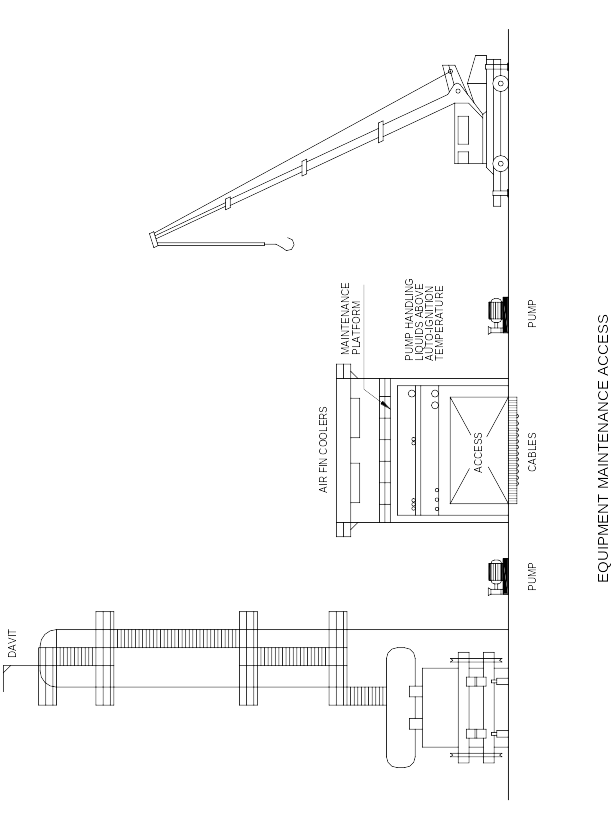

Air-fin coolers are preferably located on top of the unit piperacks. On one side of the piperack, all low equipment such as horizontal heat exchangers, pumps, etc., are to be located and on the opposite side, high equipment such as columns, vertical drum, structures, etc., are located. In this way a crane can be operated to reach all equipment, see below Figure 3 .

On the other side of the main pipe bridge, furnaces and heaters can be located with a minimum distance of 50 ft (15 m) from process equipment, and 15 ft (5 m) from the main pipe bridge. Reactors and heat exchangers associated with the furnace area, and which are also above auto-ignition temperature, may be located within 50 ft (15 m) of the furnaces.

Plot Plan

General

A process area plot plan shall be produced by the Vendor/Contractor preferably at a scale of1/8in = 1 ft (1:100 m) or at a scale specified by the Owner. The battery limit "BL" of the process area plot plan shall be clearly defined to establish the contractor's responsibilities. Each corner of the "BL" shall be identified using the established plant grid co-ordinates of northings and eastings "NE". The plot plan shall show the used location of all equipment, piperacks, buildings and access roads. Major maintenance areas for exchanger bundle pulling, etc., shall also be shown. A table on the right-hand side of the drawing shall list all equipment items with their designation, titles and with base support or centreline elevations.

Equipment Designation

All equipment shown on the plot plan shall be designed and classified as follows:

- Class A - Packages

- Class B - Boilers and Deaerators

- Class C - Columns or Towers

- Class D - Drums

- Class E - Exchangers or Condensers

- Class F - Furnaces

- Class GT - Gas Turbines

- Class K - Compressors

- Class M - Miscellaneous or Special Equipment

- Class P - Pumps

- Class R - Reactors or Dehydrators

- Class ST - Steam Turbines

- Class T - Atmospheric Storage Tanks

- Class V - Pressurised Storage Vessels

- Class WD - Well Heads

Elevations

A datum level of 100'-0" (100.000 m) shall be established for the process plot area. This datum is the height of finished grade, and is the equivalent of the national survey datum for the area.

For example: datum elevation 100'-0" = 15'-3" national datum, or(datum elevation 100.000 m = 4.650 M)

Escape Routes

Designated emergency escape routes shall be shown on the plot plan. These routes shall be as straight and as easy as possible for access. Escape routes shall not be impeded in any way by equipment or piping and shall be a minimum of 6'-6" (2m) wide when used as a walkway.

Spacing of Process Equipment

Within process plot limits, the location of process equipment and major facilities, such as control buildings, electrical substations, etc., shall be determined in accordance with the Spacing Chart, Table 1A (1B), with consideration given to the proximity of adjoining facilities, prevailing wind direction and site topography.

Pipe Racks

General

A minimum distance should be maintained between the outside edge of equipment and a piperack to prevent a `chimney' effect in case of a fire see table 1A (B). This free space can also provide maintenance access.

An exception of this rule may be made for pumps, subject to Owner's approval.

Clearances

An access clearway, 16ft (5m) wide by 18ft (5.5m) clear high shall be provided under the entire length of the main pipe rack. The clearway should not be obstructed by ladders, equipment etc., and shall be accessible from the main plant road from both ends. Secondary pipe racks shall have an access of 12ft (3.6m) wide by 14ft (4.2m) clear height shall be provided under the entire length. A clear height of 18ft (5.5m) under major pipeways shall also be provided for major mobile equipment and fire fighting access, all other process pipeways shall have a minimum clear height underneath of 14ft (4.2m).

Pipe racks located near hazardous equipment shall be fireproofed. The fireproofing shall include all the steel support columns, beams, and bracing, the top face of the beam flange does not require fireproofing.

Piping located at ground level on sleepers shall have a minimum clearance from the finish grade (refer to related specification).

Note: Corner columns at junctions with the main pipe rack, shall be protected by a curb or steel ers.

Access Roads within Process Plot Limits

General

The process area shall be provided with (all weather surface) access roads for fire-fighting, maintenance, and operations. Access roads shall be wide enough to provide space to manoeuvre during fire fighting.

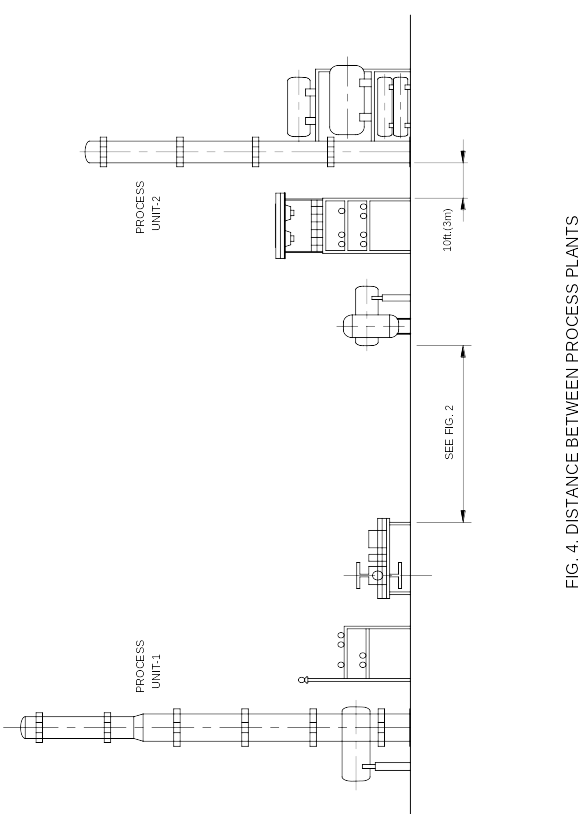

Provision shall be made for at least two entrances to a process area from a main plant road system. (See below Figure 4).

Clearances and Dimensions

Main access roads within the process area shall be 20 ft (6 m) wide. Minor accessways shall be 13 ft (4 m) wide. A minimum distance of 20 ft (6 m) is required from the edge of equipment to the edge of a main access road. The distance between two major intersections should not exceed 100 ft (30 m). A minimum distance of 6 ft (2 m) is required from the edge of equipment to the edge of minor accessways.

Major Maintenance Areas

Requirements for drop-out areas, laydown areas and bundle pulling areas shall be considered in the layout. All of these areas shall have direct access to plant access roads.

Bundle pulling areas should not encroach upon major access roads.

Access Clearances

Minimum clearances for operator and maintenance access shall be as follows:

(a) Overhead Clearances

Over plant roads for major mobile equipment - 18 ft (5.5 m)

Over process plant access roads - 14 ft (4.2 m)

Clear access under piperacks:

(i) where vehicle access is required - 18 ft (5.5 m)

(ii) for portable service equipment - 14ft (4.2 m)

Over pumps and drivers - 8 ft (2.4 m)

Personnel headroom at walkways, passageways - 7 ft (2.150 m)and platforms

(b) Horizontal Clearances

At end of pump drivers:

(i) when truck access is required - 10 ft (3.0 m)

(ii) when truck access is not required - 5 ft (1.5 m)

Distance required to remove tube bundle from - tube length, plus

exchanger (from face of shell cover flange) 2 ft (0.6 m)

Distance required to remove rear exchanger cover - 3.5 ft (1.070 m)

In front of manways (include any insulation) - 3 ft (1 m)

For walkways at grade and on elevated platforms - 2.5 ft (0.76 m)

Main operating aisles, escape routes - 4 ft (1.2 m)

Behind control panels - 4 ft (1.2 m)

Platforms, Stairways and Ladders

General

Platforms are required for operation and maintenance access for elevated equipment. All operational valves, spectacle blinds and instruments shall be accessible, and where necessary, platforms shall be installed.

Location

Platforms shall be located in accordance with related specification. Stairs and ladders shall be provided and located in accordance withrelated specification.

In addition to the above, all ladders shall face toward the equipment or structure being served. All stair and ladder locations at grade for major equipment and structures shall have clear access to a plant road for emergency escape.

PROCESS EQUIPMENT LAYOUT

Structures for Equipment

General

Structures shall be provided for equipment that is elevated for process requirements, (i.e. a reflux cascade system for a column or tower, or where there is a lack of plant space). The last option shall be minimised because of additional cost and increased fire risk.

Location

A minimum clearance of 10 ft (3 m) is required between the outside face of structure columns and the outside face of piperack columns. Where the structure is adjacent to equipment, a minimum clearance of 10 ft (3.0 m) is required between the edge of equipment to the outside face of structure columns.

Whenever possible, the centreline of structure columns should line up with the centreline of piperack columns to facilitate ease of pipe routing.

For details of steelwork structures, see related specification. For details of concrete structures, see related specification.

Spacing

Horizontal spacing of equipment contained within a structure shall conform to Table 1A (1B), Spacing Chart. The overall horizontal dimensions of the structure shall contain the limits of the equipment without any overhang. A minimum of 3 ft (1.0 m) wide access is required between equipment and associated piping and the edge of the structure platform.

Vertical spacing between structure levels shall provide adequate vertical clearances for the normal operation and maintenance of equipment and piping.

Access

Main access to the structure shall be by a stairway at the side of the structure, unless it is a minor structure of one level only and is 12 ft (3.7 m) high or less, when a ladder will suffice.

The escape route shall be by ladder access, diagonally opposite to the main stair access.

The stairway shall not be located between the structure and a piperack, or between the structure and a maintenance access road.

Maintenance

Consideration shall be given to the maintenance of exchangers and other equipment on intermediate levels of the structure. Runway beams or davits (where necessary) shall be provided for exchanger bundle pulling or bonnet removal, etc.

Pumps

General

Pumps shall be installed alongside the piperack with the pump centrelines at 90 to the piperack, with a minimum clearance from the back of pumps to the piperack column centreline of 5 ft (1.5 m). All pump drivers shall face towards the piperack.

Access

All pumps shall be accessible for operation and maintenance, with a minimum access of 3 ft (1 m) between the pumps. This access shall be clear of obstructions such as valve handwheels, pipe manifolds, etc. Particular consideration shall be given to steam turbine drivers to provide adequate clearance from the steam piping to the adjacent pump. Auxiliary equipment for large capacity pumps, such as lube and seal oil consoles, shall be allowed for in the layout. Suction, discharge and auxiliary piping shall not cross over the pumps and drivers.

Spacing

Spacing in relationship to other equipment shall be governed by the Spacing Chart, Table 1A (1B).

Location

Pumps a source of hydrocarbon leakage shall not be located below tower platforms, structures, elevated drums, air-cooled heat exchangers or piperacks. Pumps shall be mounted on a concrete base with a minimum height of 200 mm above grade to the pump baseplate.

Compressors

General

Compressors shall generally be located in a compressor house or shelter. The steel framework of the building shall carry a travelling crane for machinery maintenance. The sheeting walls of the compressor shelter are normally open sided, with a minimum clear height of 8 ft (2.5 m) from grade to the underside of the sheeting.

Large centrifugal compressors shall normally be elevated and mounted on a concrete table top, to facilitate gravity drainage of oil systems to the lube oil and seal oil consoles located below at grade. Where a steam turbine driver is installed, additional elevation of the machine shall be provided to facilitate the arrangement of the surface condenser below the steam turbine.

Reciprocating compressors shall be located near to grade, to minimise vibration effects on the machinery foundations and on the compressor piping.

For details of structural steelwork for compressor shelters, refer to related specification.

For details of compressor foundations and concrete table tops, refer to related specification.

Location

Compressors shall be located in relation to other equipment in accordance with Table 1, except for equipment directly associated with the compressors, such as knock-out drums, lube and seal oil consoles, which may be located in the compressor area.

A compressor area shall not be located in the middle of a process plant for the following reasons:

(a) The hazardous nature of gas compressors handling hydrocarbon fluids.

(b) External construction activity at a compressor area, including installation of heavy machinery, which could have a late scheduled on site delivery. The compressor area shall be located close to or at the periphery of the process plant.

Spacing

Where two or more compressors are to be installed within a compressor shelter, the minimum spacing between machines shall be 10 ft (3 m). Compressors handling inert gas or air may be located closer to each other. Consideration shall be given to maintenance requirements, such as laydown areas, and the location of auxiliary equipment. Provision shall be made for the removal of pistons from horizontally opposed cylinder type reciprocating compressors. Steam turbine or electric motor driven compressors with drivers less than 150 kW power may be treated as pumps for spacing and location purposes.

Maintenance

The handling of component parts and removable casings of the compressor and driver shall be carried out by using a travelling crane within the compressor shelter framework.

The range of the travelling crane shall cover the entire compressor machinery area, including auxiliary equipment. Where required, in the case of a table-top arrangement, sections of the operating platform shall be made removable so that the crane can be used for handling equipment at grade.

There shall be a clear laydown area at one end of the compressor shelter, within the range of the crane. This laydown area shall form the end of an accessway 12 ft (4 m) wide that is directly connected to a main plant road.

The crane hook shall be at a minimum height to enable the largest component or casing to be lifted over the remaining equipment en-route to the laydown area with a clearance of at least 2 ft (0.6 m).

Fired Heaters and Boilers

General (Fired Heaters only)

Fired Heaters are generally of two types, the cabin or rectangular type and the vertical circular heater. Location and spacing requirements apply equally to both types.

Location

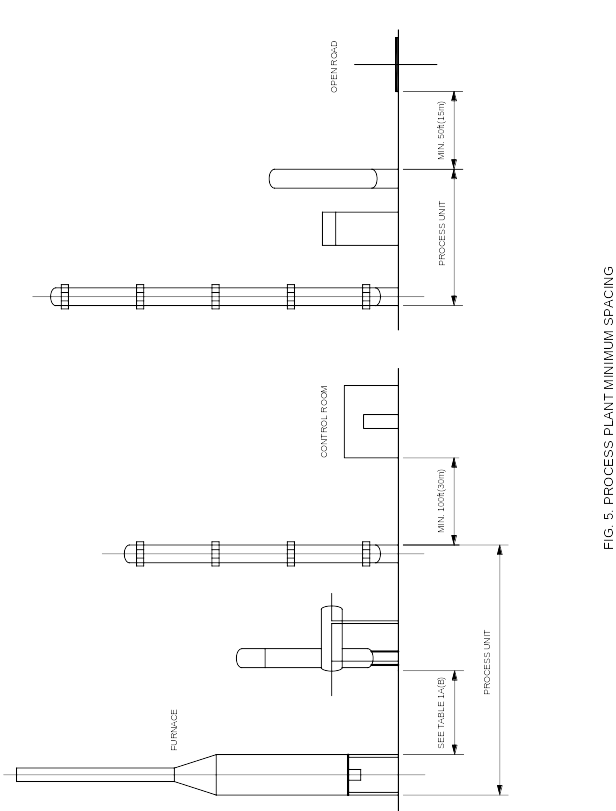

Fired Heaters and boilers form a hazard to the remainder of the process plant because of their constant source of ignition. The required location shall be on the upwind side of the plant and close to the battery limit. See Figure 2 "Optimum Process Unit Layout" and Table 1A (1B) "Minimum Spacing for Refinery Chemical Plants and Oil/Gas Facilities".

Consideration should be given to any adjacent units or facilities, in particular those containing hazardous equipment. The top of a furnace stack shall be a minimum of 10 ft (3 m) above any working platform.

Note: In some circumstances a bund wall may be required around the Fired Heaters to contain spillage.

Spacing

Spacing shall be in accordance with Table 1, Minimum Spacing Chart, but generally equipment containing combustible materials shall be a minimum of 50 ft (15 m) from furnaces or heaters, except equipment directly associated with the furnaces and within the furnace areas. Spacing between furnaces shall be 25 ft (7.5 m) if the pressure at the coil inlet is 100 psig (6.8 bar g) or less, and 50 ft (15 m) if above 100 psig (6.8 barg).

Maintenance Access

In addition to the spacing requirements above, a maintenance area shall be provided for the pulling of furnace coils. This area is to be adjacent to a major plant road.

Air Intakes and Exhaust Stacks

General

Air intakes and exhaust stacks are required for certain items of equipment within a process area. For example, heating and ventilation, air compressors, forced draft furnaces, gas turbines and internal combustion engines. Additionally, atmospheric exhausts may be required for start-up systems, turbine exhausts and relief valve discharge piping.

Location

Air intakes can be a potential source of ignition, whereby they can pull in flammable vapours and create an internal explosion. The location of air intakes shall be carefully considered in relation to other equipment and the prevailing wind direction.

Atmospheric exhausts shall be located so that they do not present a hazard to personnel or equipment.

Atmospheric exhausts should thus be located a minimum of 10 ft (3 m) above any platform within a horizontal distance of 25 ft (7.5 m). Exhaust lines shall be run together, where possible, in a vertical bank to a high point of an area. Manhole vents from oily water sewer systems should be run to a piperack or structural column, and provided with a flame arrestor at the open end of the vent. They should follow the vertical and horizontal rules given above for atmospheric exhausts.

Chemical Injection Areas

General

Equipment containing caustic fluids or any other chemicals which would cause injury to the eyes or body of any person exposed to accidental spillage or leakage, shall be located in accordance with paragraph 6.6.2 below.

Location

Equipment containing caustic or other fluids hazardous to personnel shall be grouped together and shall be surrounded by a curb 6 in (150 mm) high for containment of accidental spillage. There shall be a 3.25 ft (1 m) access between the edge of the equipment and the inside edge of the curb.

An emergency shower and eyewash fountain shall be provided no further than 50 ft (15 m) unobstructed access from the caustic area. The safety shower and eyewash shall be provided with a potable water supply. Safety signs with pictorial displays shall also be provided close to the area.

Air-cooled Heat Exchangers

General

Air-cooled heat exchangers are particularly vulnerable to fire damage due to the materials used in the large surface areas required for heat transfer, thus careful consideration should be given to the location of air-fin exchangers to minimise possible loss from fire.

Location

Air-cooled heat exchangers shall be located as far away as possible from a furnace area.

Economy of process plant space and the cost effective use of structural steelwork, normally dictate that air-fin coolers are located over a piperack. The following requirements to minimise fire damage shall apply:

(a) A fire deck shall be installed below air-fin coolers when flammable gas or liquid containing equipment is installed below.

(b) Minimum headroom of 10 ft (3 m) shall be provided between the lowest part of an air-fin exchanger and the top of the piperack.

(c) Flanged joints shall be minimised in all hydrocarbon lines below air-fin exchangers.

(d) Clear access to one side of the piperack shall be provided for fire-fighting and maintenance.

(e) Column supports for piperacks and air-cooled exchangers shall be fire-proofed as far as the air-cooled exchanger supports.

Towers/Columns

Location

Towers/columns shall be located along the pipe rack towards open areas, to allow unobstructed erection and maintenance of internals. Tall towers require frequent operating attention at higher levels, hence (if possible) they shall be located in one place for common access.

Control Rooms/Control Buildings

Location

Control Rooms/Control Buildings shall be located distinctly in the process block or in the adjoining block. The Control Room/Building may be dedicated to one process unit or shared by two or more process units of similar function. The Control Room/Building shall be at a safe distance, where protection to personnel and instruments is ensured and non-hazard electrical area classification is permitted.

Notes:-

1. Safe distances from equipment shall be in accordance with Table 1A (B).

2. Control room/building locations in a `high' hazard process unit shall be specified as "Blast Resistant"

Electrical Sub-Stations

Location

The unit Electrical Sub-Station shall be located in a non-hazardous area, as near as possible to the "Load" centre of the area to be supplied. The sub-station shall be preferably be located adjacent to the Control Room/Buildings. When sub-stations are located within the process block limits, care shall be taken that they meet the requirements of the electrical area classification and shall not be sited in the drainage path from hydrocarbon handling equipment.

Transformers shall be located in open area at the rear of the sub-station. Each transformer shall be isolated from the others by a masonry wall.

An access road to the sub-station and transformer bays shall be provided to facilitate crane movement for erection and maintenance.

Note: Pipelines and buried facilities in the area shall be avoided.

SITE LAYOUT AND OFF-SITE

Overall Site Plot Plan

A site plot plan shall be produced by the Vendor/Contractor at a scale to suit the size of the plant and shall be agreed by the Owner, but in no case shall be less than 1/32" = 1ft (1:400m).

This drawing shall give the following information:

(a) A co-ordinate datum point (S.O.P. = setting out put) from which all site locations shall be taken with north and east coordinates.

(b) Indication of plant north, in relation to true and magnetic north.

(c) The prevailing wind direction.

(d) The finished grade level for specified areas based on the national survey datum.

(e) The perimeter site fence limits, including plant entrance gates and gate houses.

(f) The location of process units, off-site storage, utility plant, flares, vent stacks and buildings.

(g) The location and elevation of all plant access roads.

(h) Areas for future expansion.

(i) The location of pipeways and main utility services.

(j) Existing facilities or buildings adjacent to the site shall be shown where possible.

(k) All major tie-in points for product, utilities, and main services shall be identified at the battery limit.

Plant Access Roads

General

The layout of access roads shall provide a means of access for operating and normal maintenance equipment and for fire-fighting vehicles to all parts of the plant.

For design details of all roads, refer to General Engineering Specification.

Road Categories

Three classes of roads are normally used for refineries, oil and gas onshore installations and processing facilities.

(a) Primary Roads

These carry general unrestricted traffic with direct access to the public highway from the site entrances. Primary roads shall be 26 ft (8.0m) wide, with 5 ft (1.5 m) wide shoulder on each side.

(b) Plant Access Roads

These carry normal maintenance vehicles and fire-fighting equipment within the process and off-site areas. Plant access roads shall be 20 ft (6.0 m) wide, with 3 ft (1.0 m) wide shoulder on each side.

(c) Secondary or Minor Accessways

These are restricted access roads within a process or off-site area and carry mobile maintenance vehicles and cars. Accessways shall be a minimum of 12 ft (4 m) wide, with no shoulders provided.

All road categories shall be surfaced with asphalt or concrete.

Layout

The road layout shall provide access for fire-fighting vehicles to all sides of a process block, and to bunded storage areas within a tank farm.

Turning radii at road junctions shall be designed to facilitate movement of the largest fire-fighting vehicle in the event of an emergency or a minimum radii of 20 ft (6m).

A perimeter road inside the boundary fence shall be provided when specified by the Owner.

Provision shall be made for at least two entrances to process units, utility plants and tank farms. Main administration buildings and car parking shall be accessible from a primary road.

Road junctions shall be no more than 100 ft (30 m) from each other in areas where fire-fighting access is required.

Utility Plant

Utility plants shall have maximum protection with respect to location and spacing, and shall always be easily accessible in emergency conditions.

Utility plants shall be divided into two areas, one containing flammable products, such as oil, fuel oil, fuel gas, etc., and the other containing non-flammable products, i.e. instrument air, boiler feed water, water storage, nitrogen, etc. The flammable area shall be treated as a process area containing hydrocarbon and should follow the requirements laid down in Section 5 of this specification.

The steam generating facilities shall be located in the area containing flammable products. Boilers shall be located up-wind from fuel oil or diesel oil storage tanks.

Buildings

Control Buildings

The minimum distance of control buildings from process areas or other facilities containing hydrocarbon fluids shall be in accordance with Tables 1A (B).

Service Buildings

Service buildings such as administration buildings, workshops, laboratories, etc., shall be located upwind from hydrocarbon processing plant. Personnel in these buildings are not directly involved with plant operation, thus these buildings may be remotely located from the process facilities. Minimum distances from process plant and other facilities shall be in accordance with Tables 1A (B).

Analyser Houses

The location of an anaylser house should be in accordance with normal refinery practice, i.e. within the battery limits of a process area. There shall be a minimum distance of 50 ft (15 m) from furnaces. There shall be an access way of 10 ft (3 m) on all sides of the analyser house.

Paving and Drainage

Paved areas shall be decided upon after examination of the entire plant area, including roads and after taking into account the following factors:-

(a) Paved areas shall be provided to prevent hazardous liquids from soaking into the ground from machines, pumps, flange joints at vessels, control value assemblies, filters etc.

(b) Paving shall be provided where regular use of scaffolding occurs.

(c) Small areas of un-paved ground between larger areas shall be avoided.

(d) All paved areas shall be drained to convey liquid quickly to a proper underground drainage system.

OFF-SITES EQUIPMENT LAYOUT

Cooling Towers

Cooling towers shall be located downwind to minimise the effect of external corrosion on other areas of equipment from exhaust plume. Towers shall be located in accordance with Tables 1A (B) "Minimum Spacing for Refineries, Chemical Plants and Oil/Gas Facilities".

Flares and Vent Stacks

General

Flares, burn pits and vents shall be located downwind and built in an open area. The prevailing wind direction and site topography should be considered when locating a flare or vent stack.

Elevated Flares

A flare is considered elevated if it is above 50 ft (15 m) high. A sterile area is required around an elevated flare. The radius of the area is governed by the heat flux level at maximum (emergency) flaring capacity, which shall not exceed 2000 BTU/h ft2(6 kW/m2) at the edge of the sterile area.

At normal operating capacity the heat flux area shall not exceed 500 BTU/h/ft2(1.5 kW/m2) at the edge of the sterile area.

The minimum sterile area for elevated flares for refineries and petrochemical plant shall be 200 ft (60 m). Within the sterile area, only equipment and piping directly related to the flare system is allowed, and all other equipment, piperack, roads, etc., should be outside the sterile area circle.

Ground Flares and Burn Pits

Ground flares shall be located downwind and have a sterile area, whereby the maximum flaring radiation level shall not exceed 2000 BTU/h ft2(6.0 kW/m2).

A burn pit shall not exceed an area larger than 10,000 ft2(1000 m2). There should be a minimum sterile area radius of 500 ft (150 m) to allow for the disposal of smoke from the burn pit.

Special Requirement for Flare Location in a GOSP Area

The clearances given above are minimum. Actual clear areas shall be assessed on the radiant heat effects on personnel and adjacent equipment. The following minimum distances shall be used for ground flares in GOSP areas:

- 1500 ft (450 m) from production oil or gas wells;

- 500 ft (150 m) from pipeways;

- 1500 ft (450 m) from GOSP battery limits;

- 1500 ft (450 m) from public highways;

- 100 ft (30 m) from buried lines.

Minimum distances for burn pit in GOSP areas shall be as follows:

- 1500 ft (450 m) from GOSP battery limit;

- 1500 ft (450 m) from overhead transmission lines;

- 300 ft (90 m) from GOSP ground flares;

- 200 ft (60 m) from ground oil or gas lines;

- 100 ft (30 m) from buried lines.

GOSP Facilities

All facilities within the battery limits shall be located at a minimum of 1000 ft (300 m) from major roadways.

Loading Facilities

Road Tanker Loading Facilities

Loading facilities for bulk road vehicles shall be located close to the final product tanks at the periphery of the plant. Vehicles shall not have to pass through process plot areas or tank farms. Consideration shall be given to the prevention, containment and disposal of spillages.

The loading area shall be fenced with separate gates. Spacing in relation to other facilities shall be in accordance with Table 1A (B).

Marine Loading Facilities

The design of marine terminals shall be governed by the Institute of Petroleum Refinery Safety Code, Section 7.2, and related specification.

Tank Farms

General

Tank farms are a group of atmospheric storage tanks handling petroleum stocks, class I, II, III and unclassified as specified in the I.P. code stated below.

Classification of crude oil and its derivatives are given in I.P. Model Code of Safe Practice part 3, Refining Safety Code (Section 1.2).

Atmospheric storage tanks are either the floating roof or fixed roof type. Tanks shall be in a bunded area, so that spillage or a rupture of a tank can be contained and controlled.

Location

Small tank farms shall be located as in Figure 1. This arrangement provides a buffer zone between process units and public areas. Tanks shall not be located at a higher elevation than the process units, to prevent spillage flowing into a hazardous area.

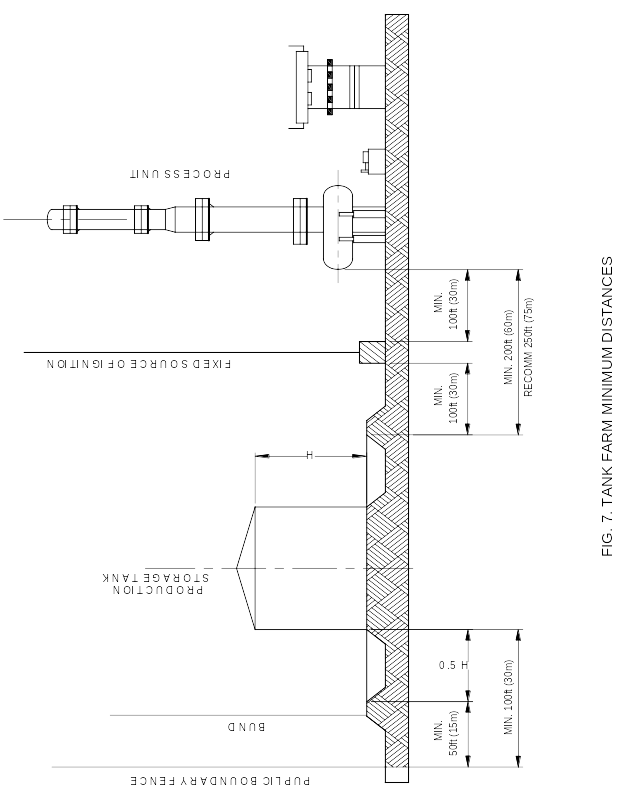

Production tanks shall be located in relation to other facilities in accordance with Tables 1A (B) and Figure 7.

Large tank farms for bulk storage shall be sited (where possible) in a remote location on elevated ground to help eliminate or reduce amount of pumping equipment required.

Spacing and Layout

(a) Tank farms shall be divided into independent risk areas in order to minimise fire risk. This restricts the capacity of tanks in one bunded area.

(b) For tank bunded areas, the following requirements apply to tank Classes I, II (2) and III (2).

In accordance with I.P. Model Code of Practice part 3, Refining Safety Code.

The maximum capacity of tanks in one bunded area is limited and shall be restricted as follows:

- Single tank - no restriction.

- A group of floating roof tanks = 750,000 bb1 (120,000 m3)

- A group of fixed roof tanks = 375,000 bb1 (60,000 m3)

- Crude capacity = not more than two tanks with neither having a greater individual capacity of 375,000 bb1 (60,000 m3).

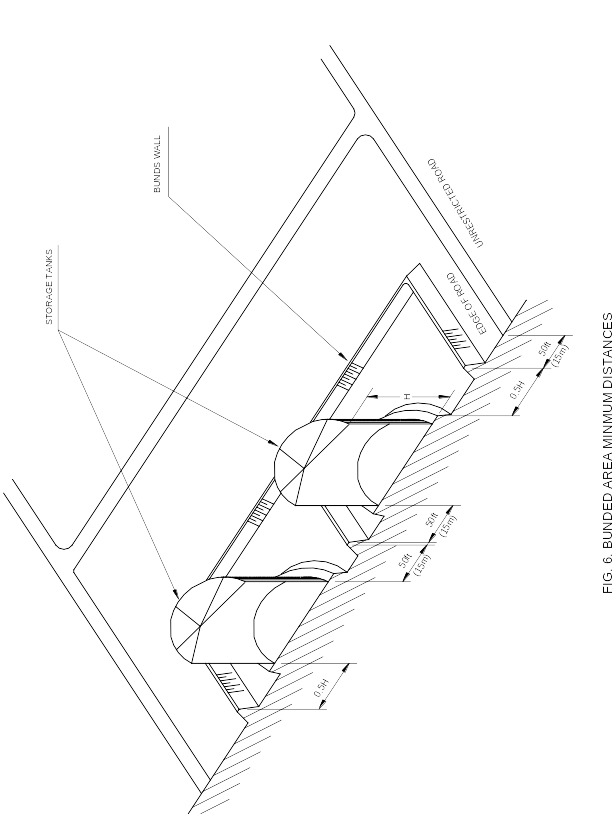

(c) The net capacity of a bunded area shall equal the capacity of the largest tank plus the cubic space occupied by the remaining tanks, up to the level of the bund wall.

This allows for one tank being breached with the remaining tanks undamaged. The height of the bund wall is determined by the net capacity of the bund, plus a free-board of 1 ft (0.3 m).

It is recommended that when calculating the size of a bunded area, a bund wall height is first selected.

The maximum height of a bund wall shall not be greater than 6.5 ft (2.0 m), unless a greater height is approved by the Owner.

The overall size of the bunded area is governed by calculation as above or by spacing limitations as shown in Figure 6.

Consideration of accessways inside the bunded area should be made when locating tanks within that area.

The spacing of a group of tanks within a bunded area shall be in accordance with the IP Refining Safety Code, Section 5. The layout of storage areas in relation to other facilities shall be in accordance with Tables 1A (B), and Figures 6 and 7.

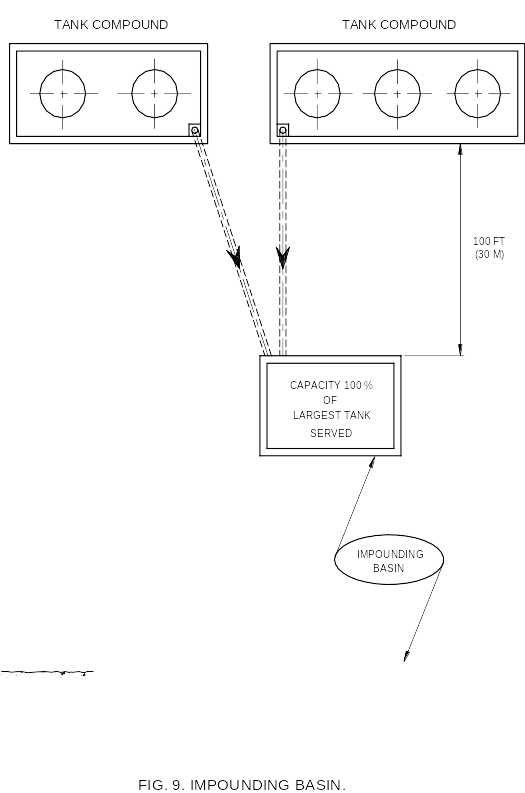

When full containment cannot be met by a bunded area, an impounding basin may be used, see Figure 9. One basin can serve up to 10 tanks or a total capacity of 6.3MM bb1 (1,000,000 m3). The capacity of the basin together with the tank enclosure, should not be less than the capacity of the largest tank served. The surface area of the basin shall be limited to 100,000 ft2(9,000m2) to facilitate fire fighting. Consideration should be given by the Vendor/Contractor to the economics of the cost of civil works in this type of installation.

Pressurised Storage

General

Pressurised LPG is normally stored in spheres or bullets. The following paragraphs provides the requirements for layout and spacing for spheres and bullets. This specification does not cover semi-refrigerated storage.

Location

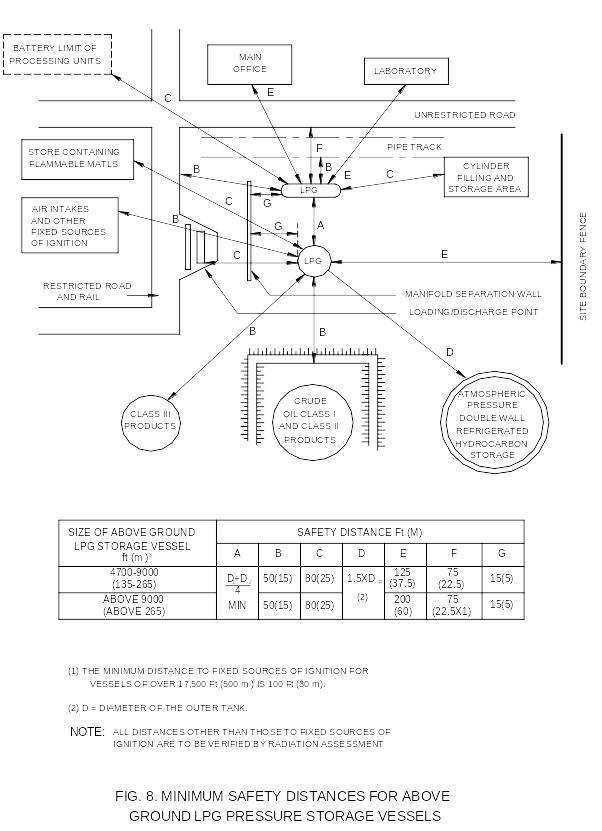

Spheres or bullets shall be located downwind from process areas, administration buildings and workshops, or residential areas. Location in relation to process units and other facilities shall be in accordance with Figure 8. Reference shall also be made to the Institute of Petroleum (IP) Model Code of Safe Practice Part 9, and to the LP Gas Association LPG Codes of Practice No 1, Part 1.

If there is any apparent conflict of information from the above codes and guidelines, the IP Code Part 9 shall be the governing criterion.

The location of pressurised storage areas shall provide easy accessibility for fire‑fighting.

Layout and Spacing

(a) Spheres

Spheres should always be located in one row. The maximum number of spheres in one group or row shall be 6. Any one group shall be separated from another by a distance of 50 ft (15 m).

The minimum distance between spheres shall be 1 x diameter of the larger sphere, with a minimum of 8 ft (2.5 m) and a maximum of 30 ft (9 m).

The sphere storage area shall be paved and provided with low walls with a maximum height of 2 ft (600 mm) on three sides, and shall slope toward a collection gutter of approximately 35 ft3(10 m3) capacity.

(b) Bullets

Bullets, either earth mounded or aboveground, shall be located side by side at a minimum separation distance of 5 ft (1.5 m) or 0.25 times the sum of the adjacent vessel diameters, whichever is the greater. Bullets shall not face spheres, process plants, control rooms etc., in case of an explosion, when the head of the bullet could act as a projectile.

Oily Water Separators and Skimming Ponds

Separators and ponds shall be located a minimum of 150 ft (45 m) from process operating areas and other sources of ignition. These facilities shall be located downwind to avoid vapours or bad odours affecting the plant. Equipment directly associated with oily water separators shall be spaced for ease of maintenance and operating access.

Comments

Haula

on 19 septembre 2024 at 03:35Dear Tidjma.tn, Thank you so much for your detailed information regarding plant layout and spacing. However, I am curious about your references to support the statements made. If possible, could you please share your list of references, particularly for the information regarding flares? Thank you!

Response :

Please refer to chapter : DESIGN-Codes and Standards

Yong

on 26 avril 2025 at 21:48You actually make it seem really easy together with your presentation butt I in finding this topic to be really something whiich I think I'd never understand. It sort of feels tooo complicated and extremely huge for me. I amm looking forward for your next publish, I will attempt to get the dangle oof it! http://boyarka-inform.com/