Reservoir Engineering

Clay

Clay: The Silent Architect of Oil & Gas Reservoirs

In the world of oil and gas exploration, the term "clay" may seem simple, but it holds a significant weight. These fine-grained minerals, often less than 4 microns in size, are a crucial component of the complex geological formations where hydrocarbons reside. While seemingly insignificant, clay plays a vital role in shaping the properties of reservoirs and influencing the extraction of oil and gas.

Beyond the Surface:

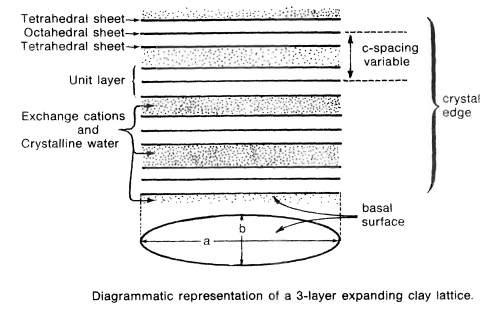

Clay minerals are primarily composed of silicate sheets, forming intricate structures at the microscopic level. In oil field jargon, the most common clay types are Smectite (montmorillinite), illite, kaolinite, and chlorite. These "authogenic clays," as they're called, exhibit an extremely high surface area-to-volume ratio, making them incredibly reactive and influential within the reservoir environment.

The Clay's Impact:

Permeability Control: Clay's high surface area and intricate structure can significantly impact the permeability of a reservoir. Clays can bind together, forming tight, impermeable layers that restrict the flow of oil and gas. Conversely, certain types of clays can act as pathways, enhancing permeability and facilitating production.

Fluid Retention: Clay minerals have an affinity for water. This affinity can lead to water retention within the reservoir, impacting the overall production of hydrocarbons. Understanding the interaction between clay and water is critical for optimizing extraction strategies.

Chemical Reactions: The reactive nature of clay minerals makes them susceptible to interactions with other elements within the reservoir. These interactions can lead to the formation of mineral scales, which can hinder production and require costly treatments.

Managing the Clay Factor:

The influence of clay on oil and gas production necessitates careful consideration and proactive management. Understanding the type and distribution of clays within a reservoir allows engineers to:

- Optimize Well Design: By mapping the distribution of clay layers, engineers can design wells that avoid problematic areas and maximize access to permeable zones.

- Predict and Prevent Formation Damage: Clay-induced formation damage, like the formation of scales, can be anticipated and mitigated through appropriate chemical treatments and well completion techniques.

- Improve Recovery: By understanding the role of clay in fluid retention, engineers can implement strategies to minimize water production and optimize hydrocarbon recovery.

The Silent Partner:

While often overlooked, clay is a crucial element in the complex tapestry of oil and gas reservoirs. Its influence on permeability, fluid retention, and chemical reactions cannot be ignored. Understanding its behavior and managing its impact are essential for successful hydrocarbon exploration and extraction. By acknowledging the role of clay, we unlock a deeper understanding of the silent architect of our energy future.

Test Your Knowledge

Quiz: Clay - The Silent Architect of Oil & Gas Reservoirs

Instructions: Choose the best answer for each question.

1. What is the primary composition of clay minerals? (a) Quartz crystals (b) Silicate sheets (c) Calcium carbonate (d) Iron oxides

Answer

(b) Silicate sheets

2. Which of the following is NOT a common type of clay mineral found in oil reservoirs? (a) Smectite (b) Illite (c) Kaolinite (d) Feldspar

Answer

(d) Feldspar

3. How can clay minerals affect the permeability of a reservoir? (a) They always increase permeability. (b) They always decrease permeability. (c) They can either increase or decrease permeability depending on the type and arrangement of clay. (d) They have no impact on permeability.

Answer

(c) They can either increase or decrease permeability depending on the type and arrangement of clay.

4. Why is it important to understand the interaction between clay and water in a reservoir? (a) Because clay can absorb water, impacting hydrocarbon production. (b) Because clay can react with water, producing harmful chemicals. (c) Because water can dissolve clay, weakening the reservoir. (d) Because water can create pathways for oil and gas to escape.

Answer

(a) Because clay can absorb water, impacting hydrocarbon production.

5. How can engineers manage the impact of clay on oil and gas production? (a) By using specialized drilling techniques to avoid clay layers. (b) By applying chemical treatments to prevent clay-induced formation damage. (c) By optimizing well design to maximize access to permeable zones. (d) All of the above.

Answer

(d) All of the above.

Exercise: Clay & Reservoir Permeability

Scenario: You are an engineer working on a new oil well. The reservoir contains a significant amount of smectite clay. Smectite is known for its swelling properties when exposed to water. Based on this information, what are your concerns regarding the well's performance and how would you address them?

Exercice Correction

**Concerns:**

* **Formation Damage:** The swelling of smectite clay when exposed to water can cause formation damage, reducing permeability and impeding oil flow. * **Water Production:** Smectite's affinity for water could lead to increased water production alongside oil, impacting overall production efficiency. * **Wellbore Stability:** The swelling clay could potentially create instability in the wellbore, leading to drilling complications and potentially even well collapse. **Addressing Concerns:**

* **Well Design:** Design the well to avoid clay-rich zones as much as possible. * **Completion Techniques:** Use completion techniques that minimize contact between the wellbore and the clay-rich formation. This could involve isolating the clay layer with a casing or using specialized completion fluids to minimize swelling. * **Chemical Treatments:** Apply chemical treatments to the wellbore to minimize clay swelling and prevent formation damage. * **Production Strategies:** Monitor water production closely and adjust production strategies to maximize oil recovery while minimizing water production. **Additional Notes:**

* It's crucial to obtain detailed geological information about the reservoir, including the distribution and properties of clay minerals. * Continuously monitor the well's performance and make adjustments as needed to optimize production and mitigate potential problems.

Books

- Clay Minerals in Petroleum Exploration and Production by David A. Spears (2013): A comprehensive overview of clay minerals, their impact on reservoir properties, and their role in exploration and production.

- Petroleum Geoscience by John Grotzinger and Thomas Jordan (2018): A textbook that covers a wide range of geological concepts, including clay mineralogy and its influence on hydrocarbon systems.

- Clay Mineralogy by Robert E. Grim (1968): A classic text on clay mineralogy, providing a solid foundation for understanding the properties and behavior of clays.

Articles

- Clay Minerals and Their Impact on Oil and Gas Production by E.S. Berner and R.A. Berner (2012): This article discusses the key ways in which clay minerals influence reservoir properties and production.

- The Role of Clay Minerals in Reservoir Characterization and Production by M.H.S. Al-Shaalan and K.M. Al-Zaabi (2015): An overview of the importance of understanding clay mineralogy for successful reservoir characterization and production.

- Clay Minerals and their Impact on Shale Gas Production by J.A. Logan and B.A. Boudreau (2016): This article focuses on the specific role of clay minerals in shale gas reservoirs, including their influence on porosity and permeability.

Online Resources

- Clay Minerals Society: This organization provides resources, publications, and research related to clay mineralogy.

- SPE Journal: This journal publishes research on various aspects of oil and gas exploration and production, including articles on clay minerals in reservoirs.

- OnePetro: A collection of online resources on various aspects of the oil and gas industry, including information on clay minerals.

Search Tips

- Use specific keywords like "clay minerals," "reservoir properties," "oil and gas production," "shale gas," "formation damage" and "permeability" to refine your search results.

- Combine these keywords with the type of clay mineral (e.g., "montmorillonite," "illite," "kaolinite").

- Include specific geographic locations (e.g., "clay minerals in the Bakken Shale") to target relevant research.

- Use quotation marks around specific phrases (e.g., "clay mineral impact on permeability") to find exact matches.

Techniques

Clay: The Silent Architect of Oil & Gas Reservoirs

This expanded text is divided into chapters for clarity.

Chapter 1: Techniques for Clay Characterization in Oil & Gas Reservoirs

The accurate characterization of clay minerals is crucial for understanding reservoir behavior. Several techniques are employed to identify clay types, their abundance, and their spatial distribution within the reservoir:

X-ray Diffraction (XRD): XRD is a primary technique for identifying clay mineral types based on their unique crystallographic structures. Quantitative XRD provides information on the relative abundances of different clay minerals. Oriented samples are preferred for better identification of clay minerals with a platy structure.

Scanning Electron Microscopy (SEM): SEM provides high-resolution images of clay particles, revealing their morphology, size distribution, and textural features. Coupled with Energy Dispersive X-ray Spectroscopy (EDS), it allows for elemental analysis of the clay minerals.

Transmission Electron Microscopy (TEM): TEM offers even higher resolution than SEM, allowing for the investigation of the clay mineral's internal structure and identification of subtle differences between clay types.

Nuclear Magnetic Resonance (NMR): NMR provides information on the pore size distribution and surface area of the clay minerals, which are crucial for understanding their impact on reservoir permeability and fluid flow.

Geochemical Analysis: Analyzing the elemental composition of the clay minerals helps in determining their origin and diagenetic history. This information can be used to predict their reactivity and influence on reservoir properties.

Well Logging: Various well logging techniques, such as gamma ray, neutron porosity, and density logs, indirectly provide information about the clay content and distribution within the reservoir. These logs often require calibration with core analysis data.

Chapter 2: Clay Mineral Models and their Impact on Reservoir Properties

Several models help predict the impact of clay minerals on reservoir properties:

Electrostatic models: These models consider the electrostatic interactions between clay particles and fluids, influencing water retention and permeability. They account for the surface charge of clay minerals and their interactions with ions in the pore water.

Hydraulic models: These focus on the impact of clay swelling and compaction on reservoir permeability and fluid flow. They incorporate parameters such as clay content, pore pressure, and effective stress.

Geochemical reaction models: These models predict the chemical reactions between clay minerals and other reservoir components (e.g., formation water, injected fluids), considering factors such as temperature, pressure, and pH. They help predict the formation of scales and other formation damage issues.

Coupled geomechanical-geochemical models: These integrated models account for the interplay between mechanical deformation (compaction, swelling) and chemical reactions within the reservoir, leading to a more comprehensive understanding of clay's influence on reservoir performance.

Many of these models are incorporated into reservoir simulators. The choice of model depends on the specific reservoir characteristics and the level of detail required.

Chapter 3: Software for Clay Analysis and Reservoir Simulation

Several software packages are available for analyzing clay data and simulating reservoir behavior in the presence of clay minerals:

Petrophysical software: Packages like Petrel, Kingdom, and Schlumberger’s Eclipse allow for the integration of clay data from various sources (core analysis, well logs) into reservoir models.

Geochemical simulation software: Software such as PHREEQC and TOUGHREACT can be used to simulate geochemical reactions involving clay minerals.

Reservoir simulators: Commercial reservoir simulators (e.g., Eclipse, CMG) incorporate models of clay behavior to predict reservoir performance, including the impact of clay on permeability, fluid flow, and formation damage.

Chapter 4: Best Practices for Managing Clay's Influence in Oil & Gas Reservoirs

Effective management of clay's impact requires a multidisciplinary approach:

Detailed characterization: Thorough characterization of clay mineralogy, distribution, and properties is essential for accurate reservoir modeling.

Integrated workflow: Integration of data from different sources (core analysis, well logs, geochemical analysis) is crucial for a comprehensive understanding of clay's influence.

Proactive formation damage prevention: Appropriate well completion techniques and chemical treatments can mitigate clay-related formation damage.

Optimized well placement and completion design: Well placement should consider clay distribution to maximize hydrocarbon production and minimize water production.

Adaptive management strategies: Regular monitoring of reservoir performance and adjustments to production strategies are necessary to account for the dynamic behavior of clay minerals.

Chapter 5: Case Studies Illustrating Clay's Impact on Reservoir Performance

Case studies from various oil and gas reservoirs illustrate the importance of understanding and managing clay's impact:

(Specific case studies would be included here, drawing on published literature. Examples might include reservoirs where clay swelling has significantly reduced permeability, or cases where clay-related formation damage has been successfully mitigated through specialized treatments.) The case studies would detail the specific clay types present, the methods used for characterization, the impact on reservoir properties, and the strategies implemented for mitigation or optimization. This section would demonstrate the practical applications of the techniques and models described in previous chapters.

- Clay-Bound Water The Unsung Hero of Clay: Unve…

- Clay Extender Clay Extenders: Thickening th…

- Clay Flocculation Clay Flocculation: A Key to O…

- Natural Clays Natural Clays in the Oil & Ga…

- Prehydrated (clay or polymer) Prehydrated: The Key to Easie…

- Clay Migration The Silent Threat: Clay Migra…

- Clay Swelling Clay Swelling: A Silent Threa…

- Mixed Layer Clays Mixed Layer Clays: A Complex …

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments