Mechanical Engineering

Classification Of Pumps

Deciphering the World of Pumps: A Classification Guide for Mechanical Engineers

Pumps, the unsung heroes of many industrial processes, are essential for moving fluids from one point to another. Understanding the different types of pumps and their classifications is crucial for choosing the right tool for the job. While various classifications exist based on application, material, or handled fluid, a more fundamental and comprehensive approach focuses on the energy transfer mechanism.

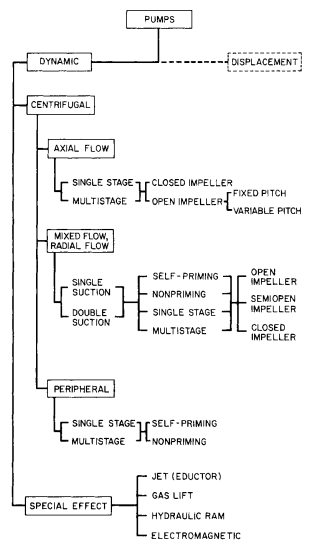

This article dives into the core classification system used in mechanical engineering, dividing pumps into two primary categories: dynamic and displacement.

Dynamic Pumps:

- Energy transfer: Continuous energy addition to increase fluid velocity. This increased velocity is subsequently converted into pressure as the fluid slows down within or beyond the pump.

- Subcategories:

- Centrifugal pumps: The most common type, using a rotating impeller to impart velocity to the fluid. They are further categorized based on impeller design (radial, mixed flow, axial), number of stages (single, multi-stage), and other factors.

- Other special-effect pumps: Include axial flow pumps, mixed flow pumps, and jet pumps, each operating on a specific principle of fluid velocity manipulation.

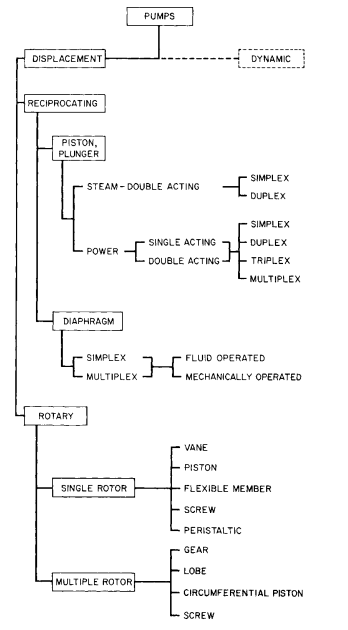

Displacement Pumps:

- Energy transfer: Periodic energy addition through the movement of a boundary, directly increasing the pressure within a confined volume of fluid.

- Subcategories:

- Reciprocating pumps: Use reciprocating pistons or plungers to displace the fluid, common examples being piston pumps, diaphragm pumps, and plunger pumps.

- Rotary pumps: Employ rotating elements like gears, screws, or vanes to displace the fluid, including gear pumps, screw pumps, vane pumps, and lobe pumps.

Beyond the Basics:

This basic classification serves as a foundation for understanding pump operation and selection. Further detailed information on specific pump types, their working principles, and applications can be found in specialized literature and engineering handbooks.

By mastering the fundamental classification system, engineers can navigate the vast world of pumps with confidence, selecting the most appropriate type for their specific needs and ensuring efficient and reliable fluid handling in any industrial application.

Test Your Knowledge

Quiz: Deciphering the World of Pumps

Instructions: Choose the best answer for each question.

1. Which of the following is NOT a subcategory of dynamic pumps?

a) Centrifugal pumps b) Reciprocating pumps c) Axial flow pumps d) Mixed flow pumps

Answer

b) Reciprocating pumps

2. How do dynamic pumps transfer energy to the fluid?

a) By directly compressing the fluid b) By increasing fluid velocity and converting it to pressure c) By using a rotating element to displace the fluid d) By creating a vacuum to draw the fluid

Answer

b) By increasing fluid velocity and converting it to pressure

3. Which of the following is a type of displacement pump?

a) Centrifugal pump b) Jet pump c) Gear pump d) Axial flow pump

Answer

c) Gear pump

4. What is the primary difference between dynamic and displacement pumps?

a) The type of fluid they can handle b) The pressure they can generate c) The energy transfer mechanism d) Their application in industry

Answer

c) The energy transfer mechanism

5. Which of the following statements is TRUE about centrifugal pumps?

a) They are primarily used for high-pressure applications b) They are always single-stage pumps c) They use a rotating impeller to increase fluid velocity d) They are more efficient than displacement pumps

Answer

c) They use a rotating impeller to increase fluid velocity

Exercise: Pump Selection

Scenario: You are tasked with designing a pumping system for a water treatment plant. The system needs to move 500 gallons per minute (gpm) of water from a reservoir to a storage tank located 100 feet above the reservoir.

Task:

- Based on the information provided, would you recommend a dynamic pump or a displacement pump for this application?

- Explain your reasoning, considering the flow rate, pressure requirements, and application.

Exercice Correction

**Recommendation:** In this scenario, a **dynamic pump**, specifically a **centrifugal pump**, would be the most suitable choice. **Reasoning:** * **Flow Rate:** Centrifugal pumps are well-suited for handling high flow rates, like the 500 gpm required in this application. * **Pressure Requirements:** Moving water 100 feet vertically requires overcoming significant head pressure. Centrifugal pumps can be designed to generate the necessary pressure for this application. * **Application:** Water treatment plants typically use centrifugal pumps for tasks like moving large volumes of water, which aligns with this scenario. While displacement pumps can be used for certain applications, they are generally less efficient for high-volume, high-pressure scenarios like this.

Books

- Fluid Mechanics by Frank M. White: A comprehensive textbook covering fluid mechanics principles, including pump theory and classification.

- Pump Handbook by Igor J. Karassik, William C. Krutzsch, et al.: A widely acclaimed reference guide with detailed information on pump types, selection, operation, and maintenance.

- Pumping Machinery by Roy C. Daugherty and Joseph B. Franzini: Another comprehensive textbook covering pump fundamentals, classification, and design.

- Centrifugal Pumps by A.J. Stepanoff: A detailed exploration of centrifugal pumps, their design, operation, and applications.

Articles

- Classification of Pumps by Machinery Lubrication: A concise article outlining the basic categories of pumps and their working principles.

- Types of Pumps and Their Applications by Engineering ToolBox: An informative article summarizing different pump types and their suitability for various applications.

- Pump Technology: A Comprehensive Overview by KSB: A company website offering a detailed overview of pump technology, including various pump types and their advantages.

Online Resources

- Pump University by Goulds Pumps: An extensive online resource covering pump fundamentals, selection, operation, and troubleshooting.

- Fluid Mechanics for Engineers by MIT OpenCourseware: A free online course covering fluid mechanics principles, including pump theory and applications.

- Wikipedia - Pump : A detailed overview of pumps, their history, working principles, and classifications.

Search Tips

- Use specific keywords like "pump classification," "types of pumps," "dynamic pumps," "displacement pumps," and "centrifugal pumps."

- Combine keywords with specific pump types, for example, "gear pump classification" or "screw pump operation."

- Explore advanced search operators like "site:gov" or "site:edu" to find resources from government websites or educational institutions.

- Utilize image search to find visual representations of different pump types.

Techniques

Deciphering the World of Pumps: A Classification Guide for Mechanical Engineers

This expanded guide delves deeper into pump classification, breaking down the information into distinct chapters for clarity and comprehensive understanding.

Chapter 1: Techniques for Pump Classification

Pump classification relies primarily on the method of energy transfer to the fluid. This fundamental principle divides pumps into two main categories:

Dynamic Pumps: These pumps continuously add energy to the fluid, increasing its velocity. This kinetic energy is then converted into pressure as the fluid slows down. The key characteristic is the continuous flow nature. Analysis techniques for dynamic pumps often involve examining flow patterns, pressure gradients, and impeller designs using computational fluid dynamics (CFD) and experimental methods like flow visualization.

Displacement Pumps: These pumps add energy intermittently, typically by changing the volume of a chamber containing the fluid. This directly increases the pressure. The flow is pulsating rather than continuous. Analysis for these pumps might involve examining the geometry of the pumping chambers, valve timing, and fluid compressibility.

Further classification within these categories often involves considerations like:

- Flow rate: Volume of fluid moved per unit time.

- Head: The vertical distance the pump can lift the fluid, representing pressure.

- Efficiency: Ratio of output power to input power.

- Fluid properties: Viscosity, density, corrosiveness, etc., influencing material selection and pump design.

- Application: Specific industrial process or application dictates pump choice.

Chapter 2: Models of Pumps

Understanding the underlying models helps predict pump performance and select appropriate equipment. These models can be broadly categorized as:

Empirical Models: Based on experimental data and correlations. These models are useful for predicting performance within the range of tested conditions but may lack accuracy outside that range. Examples include affinity laws for scaling pump performance.

Theoretical Models: Derived from fundamental fluid mechanics principles. These models offer a deeper understanding of pump behavior and can be applied to a wider range of operating conditions. However, they may require simplifying assumptions and may not always accurately capture real-world complexities. Examples include models based on the Navier-Stokes equations for flow prediction in pump impellers.

Computational Fluid Dynamics (CFD) Models: Use numerical methods to solve the governing fluid mechanics equations for complex geometries. These provide detailed flow patterns and performance predictions, but are computationally intensive and require expertise.

Specific models exist for different pump types, reflecting their unique operating principles. For example, centrifugal pump models account for impeller geometry, blade angles, and flow velocities, while reciprocating pump models consider piston motion, valve timing, and fluid compressibility.

Chapter 3: Software for Pump Selection and Analysis

Various software packages are available to aid in pump selection, analysis, and design:

Pump selection software: These programs allow users to input application requirements (flow rate, head, fluid properties) and select suitable pumps from a database. They often provide performance curves and cost comparisons.

CFD software: Packages like ANSYS Fluent, COMSOL Multiphysics, and OpenFOAM allow detailed simulation of fluid flow within pumps, enabling optimization of designs and prediction of performance under varying conditions.

Performance prediction software: Software specifically designed to predict pump performance characteristics based on geometric parameters and operating conditions.

CAD software: Used for creating and modifying 3D pump designs, facilitating the integration of simulations and allowing for improved design optimization.

The choice of software depends on the specific needs, from simple selection to detailed analysis and design.

Chapter 4: Best Practices in Pump Selection and Operation

Optimizing pump selection and operation is crucial for efficiency and longevity. Best practices include:

Accurate needs assessment: Precisely define the required flow rate, head, fluid properties, and operating conditions before selecting a pump.

Proper sizing: Select a pump with sufficient capacity to meet peak demands while considering future expansion needs.

Material compatibility: Ensure the pump materials are compatible with the handled fluid to prevent corrosion or degradation.

Regular maintenance: Implement a schedule for routine inspection, cleaning, and repair to prevent failures and ensure optimal performance.

Energy efficiency: Select high-efficiency pumps and implement strategies to reduce energy consumption, such as variable speed drives.

System optimization: Design the entire pumping system (piping, valves, etc.) for optimal flow and minimizing energy losses.

Chapter 5: Case Studies in Pump Application

Analyzing real-world examples provides valuable insights into pump selection and applications:

Case Study 1: Water supply system: Discuss the selection of centrifugal pumps for large-scale water distribution networks, considering flow rates, head requirements, and energy efficiency.

Case Study 2: Chemical processing plant: Analyze the choice of specific pumps (e.g., positive displacement pumps) for handling corrosive or viscous fluids, highlighting material selection and safety considerations.

Case Study 3: Oil and gas industry: Showcase the application of specialized pumps for handling high-pressure fluids or slurries, emphasizing reliability and durability requirements.

Case Study 4: HVAC systems: Illustrate the use of various pump types in heating, ventilation, and air conditioning systems, considering energy efficiency and noise reduction.

These case studies demonstrate how various pump types are applied in diverse contexts, emphasizing the importance of careful selection and system design.

- Actual Cost of Work Performed ("ACWP") Understanding Actual Cost of …

- Actual Cost of Work Performed ("ACWP") Understanding the Actual Cost…

- Actual Cost of Work Performed ("ACWP") Understanding the Actual Cost…

- Actual Cost of Work Performed ("ACWP") Understanding ACWP: The True …

- Actual Cost of Work Performed ("ACWP") Understanding Actual Cost of …

- Basis of Estimate Unpacking the "Basis of Estim…

- Area of Project Application Area of Project Application: …

- Area of Project Management Application ("APMA") Understanding the Area of Pro…

- As-of Date As-of Date: The Snapshot in T…

- back off Back Off: A Crucial Maneuver …

- Back Off Back Off: A Critical Step in …

- Bearden Unit of Consistency The Bearden Unit of Consisten…

- Bag-Off Bag-Off: Inflatable Devices f…

- Barrels of Oil Equivalent, BOE Unpacking the Barrel: Underst…

- Benefits Profiles Benefits Profiles: A Crucial …

- Best and Final Contract Offer Best and Final Contract Offer…

- Bill of materials Bill of Materials: The Bluepr…

- Bill of Materials Decoding the Bill of Material…

- Best and Final Offer Best and Final Offer: A High-…

- Bills of Materials The Backbone of Production: U…

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments