Forage et complétion de puits

Casing

L'épine dorsale de la production pétrolière et gazière : comprendre le tubage dans le forage et l'achèvement des puits

Le processus d'extraction du pétrole et du gaz des profondeurs de la Terre est une entreprise complexe et soigneusement orchestrée. L'un des composants essentiels de cette opération est le **tubage**, un élément crucial de la conception des puits qui constitue le fondement même d'une production sûre et efficace.

**Qu'est-ce que le tubage ?**

Le tubage fait référence à une ou plusieurs rangées de tubes en acier, généralement avec des raccords filetés, qui sont descendues dans le puits foré. Il agit comme une **barrière**, empêchant le mouvement non désiré des fluides entre les différentes formations géologiques et l'environnement environnant. En essence, le tubage agit comme un bouclier protecteur, garantissant que le puits reste stable et que les hydrocarbures extraits atteignent la surface sans contamination.

**Pourquoi le tubage est-il essentiel ?**

Le tubage joue un rôle vital dans de multiples aspects du forage et de l'achèvement des puits :

- **Stabilité du puits :** Le tubage fournit un support structurel au puits, empêchant son effondrement, en particulier dans les formations instables.

- **Contrôle des fluides :** Le tubage isole les différentes couches géologiques, empêchant le mélange des fluides provenant de différentes zones. Ceci est crucial pour une production efficace et pour garantir l'intégrité du puits.

- **Protection de l'environnement :** Le tubage empêche la migration des fluides produits, comme le pétrole ou le gaz, dans les aquifères environnants ou d'autres sources d'eau, protégeant ainsi l'environnement.

- **Sécurité :** Le tubage contribue de manière significative à la sécurité globale des opérations de forage et d'achèvement des puits en fournissant un environnement stable et contrôlé.

**Cimentation du tubage :**

Pour améliorer encore son efficacité, le tubage est généralement **cimenté** en place. Ce processus consiste à pomper une boue de ciment entre le tubage et la paroi du puits. Le ciment durcit et forme une barrière solide et imperméable qui fixe le tubage et crée un joint permanent.

**Types de tubage :**

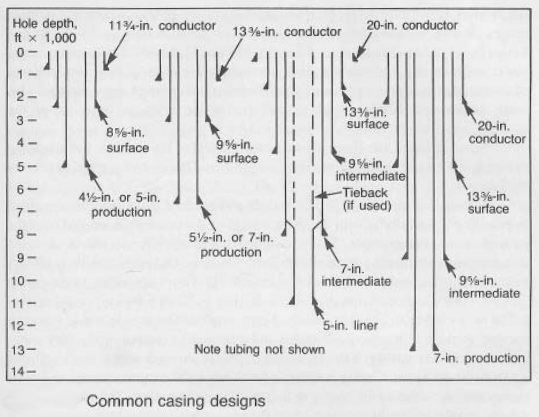

Différentes conceptions de puits peuvent nécessiter différents types de tubage, chacun servant un but spécifique :

- **Tubage de conducteur :** La première rangée de tubage installée, elle permet de stabiliser la partie supérieure du puits et fournit un chemin pour la circulation de la boue de forage.

- **Tubage de surface :** Ce tubage est posé sous le tubage de conducteur et isole les zones d'eau douce du puits.

- **Tubage intermédiaire :** Ce tubage est posé entre le tubage de surface et le tubage de production, fournissant une isolation zonale supplémentaire et stabilisant davantage le puits.

- **Tubage de production :** La dernière rangée de tubage, elle isole la zone de production et permet l'écoulement des hydrocarbures vers la surface.

**Conclusion :**

Le tubage est un élément fondamental du forage et de l'achèvement des puits, servant d'épine dorsale à une production d'hydrocarbures sûre et efficace. Son rôle dans la garantie de la stabilité du puits, du contrôle des fluides, de la protection de l'environnement et de la sécurité ne saurait être surestimé. Comprendre les différents types de tubage et leurs fonctionnalités est crucial pour toute personne impliquée dans l'industrie pétrolière et gazière. Alors que nous continuons à explorer et à extraire des ressources des profondeurs de la Terre, l'importance du tubage pour maintenir des opérations durables et responsables ne fera que croître.

Test Your Knowledge

Casing Quiz:

Instructions: Choose the best answer for each question.

1. What is the primary function of casing in oil and gas drilling?

(a) To provide a pathway for drilling mud circulation (b) To isolate different geological layers and prevent fluid mixing (c) To stabilize the wellbore and prevent collapse (d) All of the above

Answer

The correct answer is (d) All of the above.

2. Which type of casing is typically installed first?

(a) Production casing (b) Surface casing (c) Intermediate casing (d) Conductor casing

Answer

The correct answer is (d) Conductor casing.

3. What is the main purpose of cementing the casing?

(a) To enhance the strength of the casing itself (b) To create a barrier between the casing and the borehole wall (c) To prevent corrosion of the casing (d) To reduce the weight of the casing string

Answer

The correct answer is (b) To create a barrier between the casing and the borehole wall.

4. Which of the following is NOT a benefit of using casing in well drilling?

(a) Increased drilling speed (b) Improved wellbore stability (c) Enhanced environmental protection (d) Reduced risk of blowouts

Answer

The correct answer is (a) Increased drilling speed.

5. What is the primary purpose of the production casing?

(a) To isolate freshwater zones from the wellbore (b) To provide a pathway for drilling mud circulation (c) To isolate the producing zone and allow hydrocarbon flow to the surface (d) To stabilize the upper portion of the wellbore

Answer

The correct answer is (c) To isolate the producing zone and allow hydrocarbon flow to the surface.

Casing Exercise:

Scenario: You are working on a drilling project and the well plan includes the following casing strings:

- Conductor Casing: 20-inch diameter, 80 feet deep

- Surface Casing: 13 3/8-inch diameter, 1500 feet deep

- Intermediate Casing: 9 5/8-inch diameter, 4000 feet deep

- Production Casing: 7-inch diameter, 10,000 feet deep

Task: Create a simple diagram showing the placement of each casing string in the wellbore, indicating the depth of each string and the corresponding diameter.

Exercice Correction

Your diagram should show the casing strings stacked in the wellbore, starting with the conductor casing at the top and going down to the production casing at the bottom. Each string should be labeled with its diameter and depth. The diagram might look something like this:

|-------------| 20" - 80 feet (Conductor Casing) |-------------| 13 3/8" - 1500 feet (Surface Casing) |-------------| 9 5/8" - 4000 feet (Intermediate Casing) |-------------| 7" - 10,000 feet (Production Casing)

You can also use a more visual representation like a simple vertical line with the different casing sections labelled and sized appropriately. The key is to show the relative depths and diameters of each casing string.

Books

- "Petroleum Engineering: Drilling and Well Completion" by William C. Lyons

- "Drilling Engineering" by Robert F. Mitchell and Paul D. Valentine

- "Fundamentals of Reservoir Engineering" by John C. Donaldson and Harold H. Ramey Jr.

- "Well Completion Engineering" by Thomas F. Zaba and Robert M. Campbell

Articles

- "Casing and Cementing Technology" by Society of Petroleum Engineers (SPE)

- "Casing Design and Selection" by Schlumberger

- "Casing Integrity: A Critical Review" by SPE

- "The Importance of Casing in Well Construction" by Halliburton

Online Resources

- Society of Petroleum Engineers (SPE) - https://www.spe.org/

- Schlumberger - https://www.slb.com/

- Halliburton - https://www.halliburton.com/

- Baker Hughes - https://www.bakerhughes.com/

- Drillinginfo - https://www.drillinginfo.com/

Search Tips

- "Casing design oil & gas"

- "Casing installation procedures"

- "Casing failure analysis"

- "Casing cementing techniques"

- "Types of casing strings"

- "Casing inspection methods"

- "Casing and environmental regulations"

Techniques

Chapter 1: Techniques in Casing Operations

This chapter details the various techniques employed during casing operations, focusing on the practical aspects of installation and cementing.

1.1 Casing Running:

The process of lowering the casing string into the wellbore is a crucial step. This involves carefully controlling the descent to avoid damage to the casing or the wellbore. Techniques include:

- Free Fall: A faster method suitable for shorter strings and stable wellbores. Requires careful monitoring to prevent damage.

- Controlled Descent: Uses a traveling block and crown block system, offering greater control over the lowering speed and preventing damage in challenging formations.

- Casing Running Tools: Specialized tools are employed to guide the casing, manage tension, and facilitate connections. These may include elevators, slips, and power tongs.

1.2 Cementing:

Cementing the casing is essential for wellbore integrity and zonal isolation. This section covers various cementing techniques:

- Primary Cementing: The initial cementing operation after casing placement. This uses a slurry pumped between the casing and the wellbore to form a solid seal. Factors influencing this include slurry design (density, rheology), placement techniques (displacement, centralizers), and zonal isolation requirements.

- Secondary Cementing: Used to repair damaged primary cement jobs or to enhance zonal isolation. This may involve squeezing cement through perforations or using specialized techniques to reach specific zones.

- Plug and Perf Cementing: A method where the cement is selectively placed in specific zones using plugs and perforations. This improves efficiency and minimizes cement usage.

1.3 Testing and Evaluation:

After cementing, testing is crucial to ensure the integrity of the casing and cement. Common techniques include:

- Pressure Testing: Applying pressure to the casing to check for leaks in the cement or casing itself.

- Cement Bond Logging: Measuring the bond strength between the cement and the casing, and the cement and formation.

- Temperature Logging: Assessing the cement quality and identifying potential channels or voids.

Chapter 2: Casing Models and Design

This chapter discusses the various models and considerations involved in designing casing strings for specific well conditions.

2.1 Casing Selection:

The selection of appropriate casing is critical and depends on several factors:

- Wellbore Geometry: Diameter, depth, and inclination of the wellbore influence casing size and grade.

- Formation Pressure: The pressure exerted by the formations dictates the required casing strength and pressure rating.

- Formation Properties: The strength and stability of the surrounding formations influence the need for support and isolation.

- Fluid Properties: The type and properties of the fluids in the wellbore influence casing material selection (e.g., corrosion resistance).

2.2 Stress Analysis:

Analyzing the stress exerted on the casing is crucial to ensure its long-term integrity. This usually involves:

- Finite Element Analysis (FEA): Sophisticated models used to predict casing stresses under various load conditions.

- Simplified Analytical Models: Less computationally intensive models used for initial assessments.

- Collapse and Burst Pressure Calculations: Determining the maximum pressure the casing can withstand before failure.

2.3 Casing String Design Optimization:

Optimizing casing string design involves balancing various factors, including cost, wellbore stability, and operational safety. This often requires iterative calculations and simulations to achieve the most suitable design.

Chapter 3: Software Used in Casing Design and Operations

This chapter covers the software applications used in casing design, analysis, and operations.

3.1 Casing Design Software:

Several specialized software packages are employed for casing design and analysis:

- Well Engineering Software: Such as Landmark's OpenWorks, Schlumberger's Petrel, and similar packages, provide modules for casing design, stress analysis, and cement modeling.

- FEA Software: Packages like ANSYS and Abaqus allow for detailed stress analysis of casing under complex loading conditions.

3.2 Data Acquisition and Management Software:

This includes software for gathering, processing, and interpreting data from downhole sensors and logging tools during and after casing operations. Examples include:

- Logging Software: Used to interpret cement bond logs, temperature logs, and other downhole measurements.

- Wellbore Surveying Software: Essential for accurate wellbore mapping and casing placement.

3.3 Simulation and Optimization Software:

Software packages can simulate the cementing process, predict cement placement, and optimize casing string designs to minimize risks and costs.

3.4 Data Visualization Tools: Tools and software for clear visualization of the wellbore, casing, and cement are necessary for effective analysis and decision-making.

Chapter 4: Best Practices in Casing Operations

This chapter highlights best practices for safe and efficient casing operations.

4.1 Planning and Preparation:

Thorough planning is essential, including:

- Well Design Review: Careful review of the well design parameters to ensure appropriate casing selection and placement.

- Risk Assessment: Identifying potential hazards and implementing mitigation measures.

- Material Selection and Quality Control: Ensuring the use of high-quality casing materials.

4.2 Execution and Monitoring:

During operations, close monitoring is critical:

- Real-time Data Monitoring: Tracking key parameters like casing tension, pressure, and temperature.

- Communication and Coordination: Maintaining clear communication between the drilling crew and engineering personnel.

- Emergency Procedures: Having well-defined procedures for handling unexpected events.

4.3 Post-Operation Verification:

After operations are complete, verification is crucial:

- Thorough Testing: Ensuring the integrity of the casing and cement through various testing methods.

- Data Analysis: Reviewing the data gathered during operations to identify areas for improvement.

- Documentation: Maintaining accurate and complete records of all aspects of the operation.

Chapter 5: Case Studies in Casing Operations

This chapter presents real-world examples highlighting successful casing operations, challenges encountered, and lessons learned.

(Note: Specific case studies would require detailed information about individual projects which is not available here. The following outlines a potential structure for each case study.)

Case Study Format:

- Project Overview: Brief description of the well and its location.

- Challenges Faced: Description of any specific difficulties encountered during the casing operation (e.g., challenging formations, equipment failure, unexpected events).

- Solutions Implemented: Details of the solutions employed to overcome the challenges.

- Results and Outcomes: The outcome of the operation, including any lessons learned.

- Best Practices Demonstrated: Highlighting best practices employed during the operation.

(Example Case Study Outline – Replace with actual case study details):

Case Study 1: Successful Casing in a High-Pressure, High-Temperature Well: This case study will describe a successful casing operation in a high-pressure, high-temperature environment, focusing on the casing design, cementing techniques, and monitoring procedures used to ensure successful well completion.

Case Study 2: Case Study of a Failed Cement Job and Remedial Actions: This case study will illustrate a situation where a cement job failed and the remedial actions taken to resolve the issue. The analysis will focus on the root cause of the failure, the corrective measures, and the lessons learned for future operations.

This structured format allows for multiple case studies to be added, showcasing a range of scenarios and experiences within casing operations. The inclusion of specific numerical data, diagrams, and images would further enhance these case studies.

- Bottom Casing Packoff Comprendre le Joint de Fond d…

- casing Le tubage : L'épine dorsale d…

- Casing-Annular Pressure Pression Annulaire du Tubage …

- casing centralizer Bien centré : Le rôle crucial…

- Casing Centralizer Garder le cap : L'importa…

- Casing Collar Log Journal des Colliers de Tubag…

- Casing Coupling Couplage de tubage : Le héros…

- casing coupling (collar) Accouplements de tubage : les…

- casing crew Les héros méconnus de la cons…

- Casing Crew Les héros méconnus du pétrole…

- casing cutter Coupe-tubage : Un outil cruci…

- Casing Cutter Coupe-gaines : L'outil de pré…

- Casing Grade Classe de tubage : L'épine do…

- casing gun Les canons de perforation : L…

- casing hanger Le Héros Insoupçonné de l'Ach…

- Casing Hanger Le héros méconnu de la produc…

- casinghead La Tête de Tubage : Un Compos…

- Casing Head Tête de tubage : Le lien cruc…

- Casing Head La tête de tubage : Un compos…

- Casing Cladding Revêtement de tubage : Colmat…

- Demande de justification des dépenses Naviguer dans la de… Planification et ordonnancement du projet

- Coût budgété du travail planifié Comprendre le Coût … Estimation et contrôle des coûts

- Les limites de batterie Comprendre les limi… Termes techniques généraux

- Outil DV Outil DV : Un éléme… Forage et complétion de puits

- SOMMAIRE TOC : Comprendre le… Termes techniques généraux

Comments