MATERIAL HANDLING INSTRUCTIONS

(1) Materials shall be handled without any damages and distortions in accordance with the following before, during and after transportation. Materials shall not be affected any serious injuries and notches by clamp.

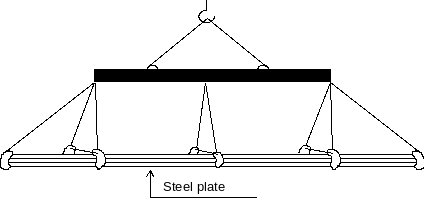

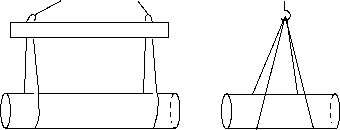

(2) Applicable type & size of spreader and numbers, length & size of wire-rope or hacker shall be suitable for lifting and handling of materials. Spreader shall be used for lifting and handling of large flat/curved rectangular plate as shown below.

or

(3) Installation of sleepers

After unloading of shell plates or steel plates from ship, or trailer, sleepers shall be installed by considering the length of shell plates or steel plates in order to keep the shell plates curvature or the flatness of steel plates.

The quantity of sleeper shall be increased to the both ends from center of shell plates or steel plates.

(4) Adjustment of the position of sleeper

On the sleepers which had been installed, one (1) sling of shell plates or steel plates shall be loaded on trial.

If the shell plates can not get a smooth curvature as specified or the steel plates do not get flatness as specified, they shall be lifted immediately from the sleepers.

After then, the sleepers shall be moved or added to adjust the position or height against soil condition of the ground.

The work mentioned above shall be done over again until the smoothing curvature or the flatness shall be got.

(5) Pipes or structural shapes longer than 5.500 mm shall be lifted by using plural wire ropes or nylon slings with spreader.

(6) Small materials and parts such as flanges, tees, etc. shall be handled by manual, hoist-crane or fork-lift depend on the size, weight, quantity and shape of them.

TRANSPORTATION INSTRUCTION

Transport of Shell Plate and/or Steel Plate

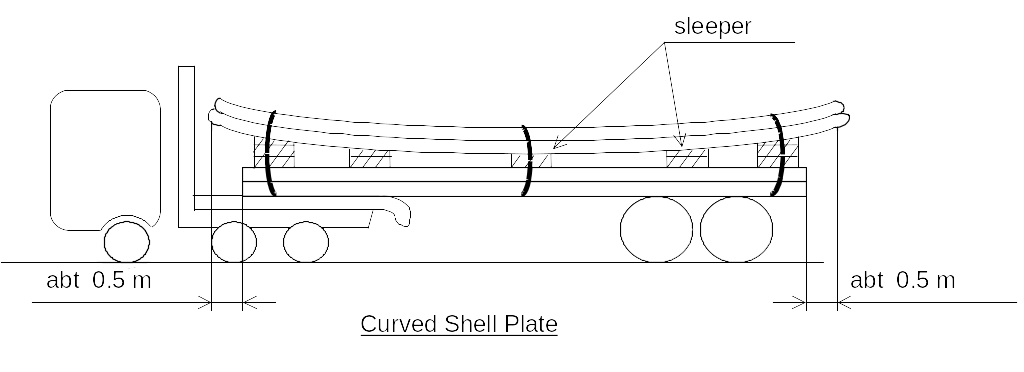

(1) Shell plate and/or steel plate shall be transported to the construction site by trailer at the suitable manner not to be caused any damages or distortions to the plates as shown below.

(2) The respective protrusion of shell plate and/or steel plates from the front and back of the bed of the trailer will normally be limited approx. 0.5 meter.

In case of the protrusion is more than 0.5 meter, sufficient length of trailer or preventive measures against damage shall be considered.

(3) The space between the protruded edge from the front and back of the trailer head has to be sufficient in order to avoid touching the steel plates edge to the trailer head in case the trailer takes a sharp turn.

(4) The position, size and quantity of sleepers on the trailer should be determined in accordance with length of the shell plates and/or steel plates and length of trailer for the purpose of keeping the curvature of the shell plate and/or the flatness of steel plates as specified.

(5) Shell plate and/or steel plate shall be fastened to the bed of trailer at the appropriate internals with wire or chain in order to avoid the sliding the plates.

Or

(6) Transportation shown below which the length of trailer is shorter than the length of shell plate and/or steel plates shall be prohibited.

In case of the condition as below will be expected, sufficient length of trailer or preventive measures against damage shall be considered.

Or

STORAGE INSTRUCTIONS

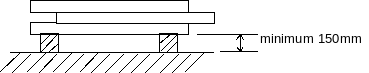

All materials should not be stored directly on the ground.

The dunnage, such as sleepers, supports, pallets, etc., should be provided between the tank materials & products and ground.

All goods packaged in wooden box, especially purchasing equipments (See Table A) should be stored in the warehouse, or covered by polyethylene sheet, etc.

All large materials such as “shell plates”, bottom plates, roof plates, structural steels, pipes an covered by polyethylene sheet if necessary and other fabricated materials, etc. may be stored in the open air stock yard and

(1) Steel plates should be kept minimum 150mm away from the ground as shown below.

(2) Shell plates shall be stored as shown in Fig. 5 to keep the curvature of the shell plate as specified in stock yard, ocean vessels, barges or on trailers.

Pieces of shell plates for piles shall be decided in accordance with the capacity, capability or endurability of the bed, floor, ground, etc. of trailers, ocean vessels, barges, stock yard, etc.

SPECIAL HANDLING INSTRUCTIONS

Large Plates

When spreader is shorter than the plate, additional steel wire ropes and plate gloves shall be provided.

When plate gloves may be considered to slide from the rolled or dished plate such as shell plate, spreader with plate gloves shall be used.

When the center of gravity is not at the center of the materials such as fan shaped roof plate, plate shall be lifted at the centre of gravity.

When stainless steel plate is lifted, rubber sheet or other suitable pad shall be provided between plate and plate gloves to prevent direct contact.

Either magnet or vacuum lifter shall be used depending on the kind or type of materials.

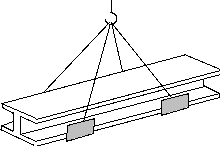

Small plates Structural shapes

Small plates or structural shapes shall be lifted by use of a spreader and or two steel wire ropes.

Rubber piece or other suitable pad shall be provided between the materials and wires to protect damages of both.

(Long size materials)

(Short size materials)

For stainless steel materials, nylon sling ropes should be used instead of steel wire ropes.

Pipes

Pipes shall be lifted by using a spreader with two steel wire ropes or a fulcrum.

(Long size pipes) (Short size pipes)

When bended pipes or pipes with elbows are lifted, the steel wire ropes shall be squeezed tightly not to slide off.

For stainless steel pipes, and coated pipes or spools, nylon sling ropes should be used instead of steel wire ropes.

Other pre-fabricated materials

Suitable lifting tools and equipments shall be used considering the shape or type of pre-fabricated materials.

Miscellaneous small or light items are handled by hand or fork-lift/crane with the pallet.

For stainless steel materials, nylon sling ropes should be used as far as practical.

When steel wire ropes and or plate gloves are used, suitable pad shall be provided between rope and material to prevent direct contact.

Comments

Craig

on June 5, 2025 at 7:46 p.m.Position certainly used.. casino en ligne Cheers, An abundance of info! casino en ligne Really a good deal of helpful knowledge. casino en ligne francais You have made your position quite well!! casino en ligne francais Valuable posts, Cheers! casino en ligne francais Many thanks! Plenty of information. casino en ligne fiable Regards. Numerous material! casino en ligne fiable Factor very well regarded!! casino en ligne Helpful content, Thanks a lot. casino en ligne Many thanks, Quite a lot of write ups. casino en ligne

Marilyn

on June 6, 2025 at 9:44 p.m.Valuable postings Regards! casino en ligne Wow plenty of valuable material! casino en ligne France With thanks. Awesome stuff! casino en ligne France You have made your position extremely clearly!! casino en ligne francais You expressed that wonderfully. casino en ligne fiable Amazing tons of fantastic tips. casino en ligne Great content Thanks! casino en ligne Many thanks. I like this. casino en ligne You said it adequately.. casino en ligne francais Superb info, Regards. casino en ligne