Reservoir Engineering

Water Coning

Water Coning: A Threat to Oil Production

Water coning is a common phenomenon in oil production that can significantly reduce well productivity and ultimately, economic viability. This article will delve into the technical details of water coning, explaining its causes, consequences, and potential mitigation strategies.

The Phenomenon:

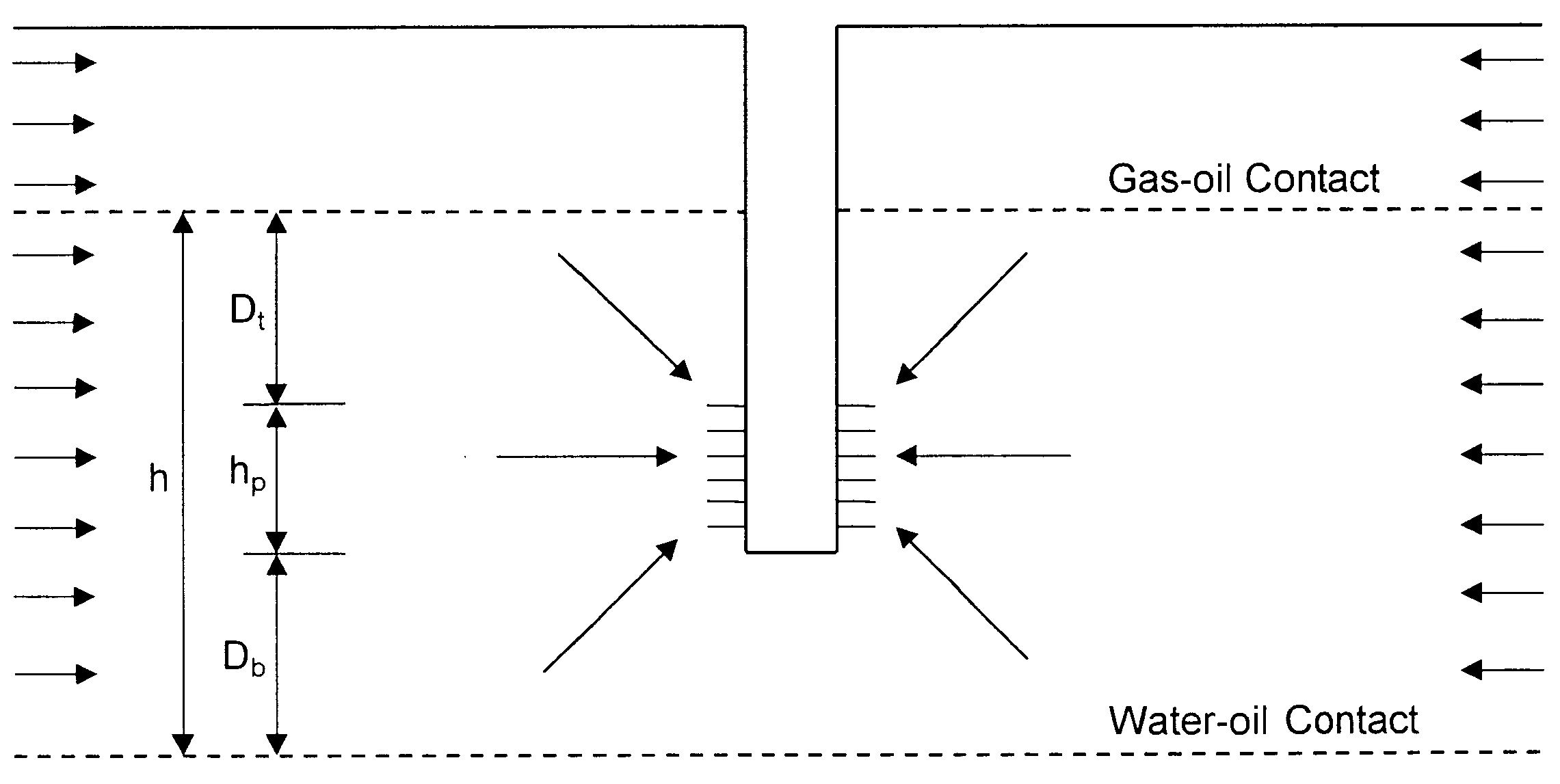

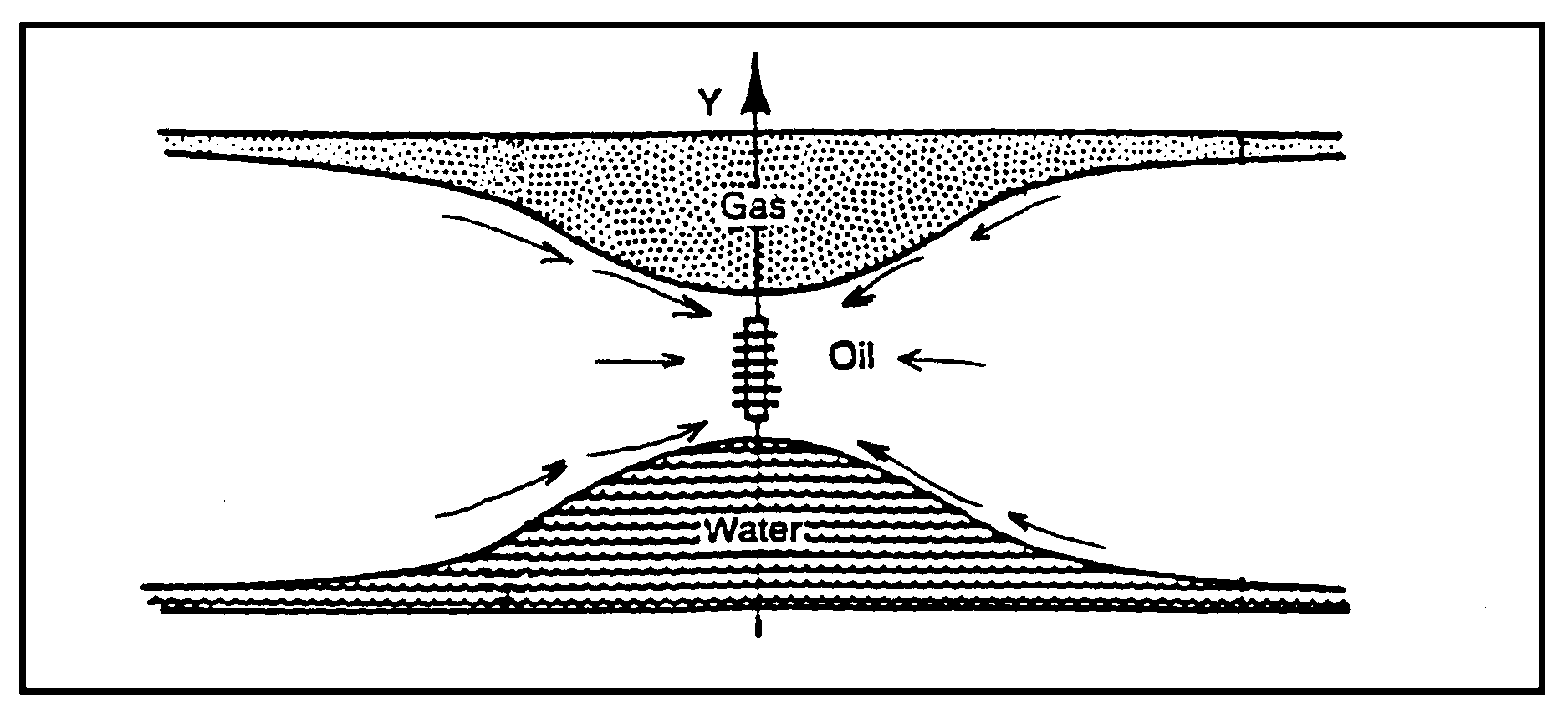

Water coning describes the upward movement of water from the underlying aquifer into the oil-bearing strata. This occurs in response to the depletion of oil and the resultant decline in reservoir pressure. As oil is extracted, the pressure difference between the oil zone and the aquifer below increases, causing water to migrate upwards along paths of high permeability. This movement, often localized to areas of high vertical permeability, can eventually lead to a "cone" of water invading the oil zone, leading to water production alongside oil.

Understanding the Mechanics:

- Pressure Gradient: The driving force behind water coning is the pressure differential between the oil reservoir and the aquifer. As oil is extracted, the pressure in the reservoir drops, creating a gradient that encourages water flow.

- Vertical Permeability: The rate and extent of water coning are heavily influenced by the vertical permeability of the rock formations. Areas with high vertical permeability provide easier pathways for water to migrate upwards.

- Well Placement: The location of the production well plays a significant role. Wells located in zones with high vertical permeability are more susceptible to water coning.

Consequences of Water Coning:

- Reduced Oil Production: The presence of water in the production stream reduces the overall volume of oil extracted.

- Increased Water Cut: Water cut refers to the percentage of water produced with oil. High water cut reduces the quality of the produced stream and increases processing costs.

- Premature Well Abandonment: Severe water coning can lead to the early abandonment of wells, especially if the water production rate becomes too high to manage economically.

Mitigation Strategies:

- Optimal Well Placement: Careful well placement is crucial to minimize the risk of water coning. Choosing locations with low vertical permeability can help minimize water movement.

- Water Injection: Injection of water back into the reservoir can help maintain pressure and counter the pressure gradient driving water coning.

- Production Rate Management: Adjusting production rates can help control the pressure difference between the oil zone and the aquifer, minimizing water coning.

- Advanced Completion Techniques: Utilizing techniques such as gravel packing and frac packing can help reduce water entry into the wellbore.

- Monitoring and Control: Continuously monitoring water cut and taking proactive measures to address water coning can help prevent premature well abandonment.

Conclusion:

Water coning is a complex phenomenon with significant implications for oil production. By understanding its causes and consequences, and employing effective mitigation strategies, producers can minimize water coning and optimize oil recovery. This is essential for ensuring the economic viability of oilfields and maximizing resource extraction.

Test Your Knowledge

Water Coning Quiz

Instructions: Choose the best answer for each question.

1. What is the primary cause of water coning? a) Increased pressure in the oil reservoir. b) Decreased pressure in the oil reservoir. c) High horizontal permeability of the rock formations. d) High density of the oil.

Answer

b) Decreased pressure in the oil reservoir.

2. Which of the following factors significantly influences the rate and extent of water coning? a) Oil viscosity. b) Water salinity. c) Vertical permeability. d) Wellbore diameter.

Answer

c) Vertical permeability.

3. What is a major consequence of water coning? a) Increased oil viscosity. b) Reduced oil production. c) Increased reservoir pressure. d) Reduced wellbore diameter.

Answer

b) Reduced oil production.

4. Which mitigation strategy involves injecting water back into the reservoir? a) Optimal well placement. b) Water injection. c) Production rate management. d) Advanced completion techniques.

Answer

b) Water injection.

5. Why is continuous monitoring of water cut crucial in managing water coning? a) To determine the oil viscosity. b) To assess the pressure in the reservoir. c) To detect and address water coning early. d) To measure the wellbore diameter.

Answer

c) To detect and address water coning early.

Water Coning Exercise

Scenario: An oil well has been experiencing increasing water production, indicating potential water coning. The well is located in a region known for its high vertical permeability.

Task:

- Identify two potential causes for water coning in this scenario.

- Suggest three mitigation strategies that could be employed to address the issue, explaining how each strategy would work in this specific context.

Exercice Correction

**1. Potential Causes:** * **High vertical permeability:** The well's location in a region with high vertical permeability facilitates the upward movement of water from the aquifer. * **Production rate:** If the production rate is too high, it can create a significant pressure differential, accelerating water coning. **2. Mitigation Strategies:** * **Reduce Production Rate:** Lowering the production rate would decrease the pressure gradient driving the water movement, slowing down coning. * **Water Injection:** Injecting water back into the reservoir would help maintain pressure and counter the downward pressure gradient. * **Advanced Completion Techniques:** Employing techniques like gravel packing could create a barrier to water flow, preventing it from entering the wellbore. This would be particularly beneficial in areas of high vertical permeability.

Books

- Petroleum Engineering Handbook: This comprehensive handbook provides detailed information on various aspects of petroleum engineering, including water coning. It covers the underlying principles, modeling techniques, and mitigation strategies.

- Reservoir Simulation: This book by Aziz and Settari delves into reservoir simulation techniques, including modeling water coning and its impact on production.

- Fundamentals of Reservoir Engineering: This book by Dake offers a thorough explanation of reservoir engineering principles, including the concept and implications of water coning.

Articles

- "Water Coning: A Review" by A.M. Al-Hussainy and R.A. Wattenbarger (Journal of Petroleum Technology, 1970): This article provides an overview of water coning, its causes, and different mitigation approaches.

- "A New Method for Predicting Water Coning" by J.C. Brigham and J.W. Woods (Society of Petroleum Engineers Journal, 1969): This article presents a mathematical model for predicting water coning and its application in reservoir management.

- "Water Coning Control by Optimized Production Rate" by D.G. Jones and R.L. Campbell (Society of Petroleum Engineers Journal, 1984): This article explores the use of production rate optimization to manage water coning and enhance oil recovery.

Online Resources

- Society of Petroleum Engineers (SPE): SPE's website offers a vast library of technical resources, including papers, presentations, and technical guides related to water coning.

- Schlumberger: Schlumberger's website provides technical information on various aspects of oil and gas production, including detailed explanations and case studies on water coning.

- Oil and Gas Journal: This journal regularly publishes articles and research reports on water coning and its impact on oil production.

Search Tips

- Use specific keywords like "water coning", "oil production", "reservoir engineering", "aquifer", "mitigation strategies" along with relevant terms like "pressure", "permeability", "well placement", "production rate".

- Include terms like "technical papers", "case studies", "research articles" in your search queries to find more relevant and detailed information.

- Utilize advanced search operators like "filetype:pdf" to focus on PDF documents, or "site:spe.org" to search within the SPE website.

Techniques

Water Coning: A Comprehensive Guide

This document expands on the provided text, breaking down the topic of water coning into separate chapters for clarity and detailed understanding.

Chapter 1: Techniques for Analyzing and Predicting Water Coning

Water coning prediction and analysis relies on a combination of empirical observations, theoretical models, and advanced simulation techniques. Understanding the reservoir characteristics is paramount. Key techniques include:

Material Balance Calculations: These calculations estimate reservoir pressure changes based on fluid withdrawal and injection. While simplified, they provide a preliminary indication of potential coning.

Pressure Transient Analysis (PTA): PTA involves analyzing pressure changes in the wellbore during production or injection. This data can be inverted to estimate reservoir properties, including vertical permeability – a crucial factor in water coning.

Well Test Analysis: Specialized well tests, such as drawdown and buildup tests, provide more detailed reservoir data for improved coning prediction. These tests help determine reservoir permeability, porosity, and skin effects.

Numerical Reservoir Simulation: Sophisticated reservoir simulation software employs numerical methods to model fluid flow in complex reservoirs. These simulations can accurately predict the movement of water and oil under various production scenarios, allowing for the optimization of well placement and production strategies. The models can incorporate detailed geological information and different fluid properties.

Analytical Models: While simpler than numerical simulations, analytical models like the Muskat model provide quick estimations of coning onset and development. These models offer valuable insights, though they rely on simplifying assumptions about reservoir geometry and properties. They are useful for initial assessments and sensitivity analyses.

Empirical Correlations: Several empirical correlations exist that relate water coning to reservoir parameters like the mobility ratio and the wellbore radius. These are quick estimations, but should be used cautiously due to their limited applicability.

Chapter 2: Models for Water Coning Prediction

Several models are employed to predict and analyze water coning, ranging from simple analytical solutions to complex numerical simulations. The choice of model depends on the available data and the desired level of accuracy.

Muskat Model: A classic analytical model that provides a simplified representation of water coning, useful for quick estimations. It makes several assumptions about reservoir geometry and fluid properties.

Dupuit-Forchheimer Model: Another analytical model that focuses on the steady-state flow of fluids in a confined aquifer. Although relatively simple, it offers insights into the long-term behavior of the cone.

Numerical Reservoir Simulation Models: These are the most comprehensive models for water coning prediction. Software packages like Eclipse, CMG, and Petrel use finite difference or finite element methods to solve complex fluid flow equations. They incorporate detailed reservoir geometry, fluid properties, and production strategies. They allow for various scenarios to be simulated.

Simplified Analytical Models: These are modifications or extensions of the Muskat or Dupuit-Forchheimer models, attempting to account for more realistic reservoir conditions such as variable permeability or wellbore storage.

The selection of the appropriate model is crucial and depends on the data availability, complexity of the reservoir, and the desired accuracy level.

Chapter 3: Software for Water Coning Analysis and Simulation

Several commercial and open-source software packages are available for water coning analysis and simulation.

Commercial Software:

- CMG: Offers a comprehensive suite of reservoir simulation tools capable of modeling complex fluid flow phenomena, including water coning.

- Eclipse (Schlumberger): A widely used reservoir simulator that includes advanced capabilities for water coning prediction.

- Petrel (Schlumberger): An integrated reservoir modeling platform that incorporates reservoir simulation, allowing for detailed analysis and prediction.

Open-Source Software: While less commonly used for industrial-scale simulations due to limitations in capabilities and validation, some open-source packages offer simplified water coning models.

The selection of software depends on the user's experience, computational resources, and project requirements. Commercial packages typically offer greater accuracy, robustness, and user support.

Chapter 4: Best Practices for Water Coning Mitigation and Management

Effective management of water coning requires a proactive and integrated approach. Best practices include:

Careful Well Placement: This is crucial to minimize the risk of early water breakthrough. Detailed reservoir characterization is essential to identify zones with low vertical permeability.

Optimized Production Strategies: Controlling production rates can help minimize the pressure differential driving water coning. This may involve adjusting production rates based on monitoring data.

Water Injection: Strategic water injection can help maintain reservoir pressure and counter the pressure gradient driving water coning.

Advanced Completion Techniques: Techniques like gravel packing and selective completion can help isolate high-permeability zones and reduce water entry into the wellbore.

Real-Time Monitoring: Continuous monitoring of water cut and pressure changes is crucial for early detection of water coning and timely intervention.

Regular Reservoir Surveillance: This includes pressure monitoring, production logging, and other techniques to track reservoir performance and identify potential issues.

Data Integration and Analysis: Combining data from various sources to build a comprehensive understanding of reservoir performance is vital for effective management.

Chapter 5: Case Studies of Water Coning and Mitigation Strategies

Case studies demonstrate how different reservoirs react to production and illustrate the effectiveness (or lack thereof) of different mitigation strategies.

(Note: Specific case studies would require detailed information on individual oil fields. The following is a template for describing a case study):

Case Study Example:

- Field Name: [Insert Field Name]

- Reservoir Characteristics: [Describe reservoir geology, fluid properties, and permeability distribution]

- Water Coning Problem: [Describe the severity and impact of water coning on production]

- Mitigation Strategies Implemented: [Detail the specific techniques used, e.g., water injection, production rate optimization, advanced completions]

- Results: [Quantify the success of the mitigation strategy in terms of reduced water cut, increased oil recovery, and economic benefits]

- Lessons Learned: [Discuss any unexpected challenges or insights gained from the experience.]

By analyzing various case studies, we can learn from past experiences, refine our understanding of water coning mechanisms, and improve the effectiveness of mitigation strategies. These studies should highlight successful strategies and those that were less effective. Detailed analyses can further enhance the understanding of the influence of various reservoir properties on the severity of water coning.

- Basic Sediment and Water or BS&W Understanding BS&W: The Hidde…

- Dewatering (fluids separation) Dewatering: A Crucial Step in…

- Free Water Knockout Free Water Knockout: The Firs…

- Bound Water Bound Water: A Silent Player …

- Bright Water TM Bright Water™: A Water Contro…

- Coning Coning: The Balancing Act of …

- Connate water Connate Water: The Unsung Her…

- Edge water Edge Water: A Stealthy Threat…

- Gas Coning Gas Coning: A Threat to Oil P…

- gone to water adj Gone to Water: The Grim Reali…

- Brackish Water Brackish Water: Where Freshwa…

- Ground Water Groundwater: The Unsung Hero …

- Clay-Bound Water The Unsung Hero of Clay: Unve…

- Formation Water Formation Water: The Hidden R…

- Condensed Water Condensed Water: A Vital Bypr…

- Cooling water Cooling Water: A Vital Compon…

- crown block and water table Crown Block and Water Table: …

- Crown Block and Water Table Crown Block and Water Table: …

- formation water Understanding Formation Water…

- Free Water Free Water: Understanding its…

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments