Drilling & Well Completion

PDC

PDC: The Cutting Edge in Drilling & Well Completion

PDC, short for Polycrystalline Diamond Compact, is a revolutionary material used in the oil and gas industry for drilling and well completion operations. Its exceptional hardness and durability make it a game-changer in cutting through challenging formations, resulting in faster drilling rates and reduced costs.

What is PDC?

PDC is a synthetic diamond material consisting of numerous small diamond crystals that are bonded together under high pressure and temperature. This unique process creates a material with exceptional hardness and wear resistance, far exceeding the capabilities of traditional drill bits made from steel.

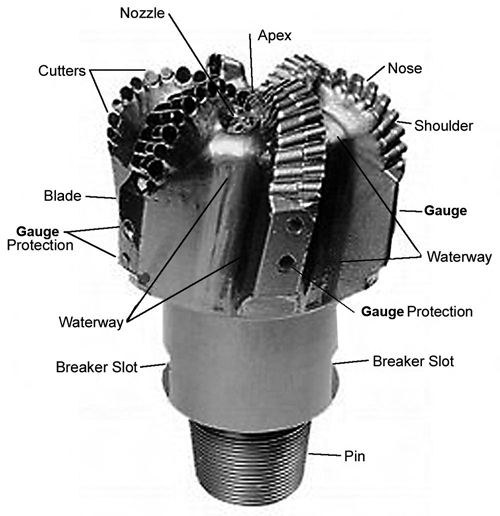

PDC Drill Bits and Cutters:

PDC bits and cutters are commonly used in various drilling applications, including:

- Rotary drilling: These bits are designed for drilling vertical or directional wells.

- Directional drilling: PDC bits are crucial for navigating complex formations and reaching targets off the vertical path.

- Horizontal drilling: PDC bits play a vital role in drilling long, horizontal sections of wells, essential for accessing unconventional resources.

- Well completion: PDC cutters are used in various completion operations, such as cutting and milling operations during well stimulation.

Key Advantages of PDC:

- Exceptional Hardness and Durability: PDC's superior hardness allows it to cut through abrasive rock formations with ease, reducing wear and tear on the bit and extending its lifespan.

- Increased Drilling Rates: PDC bits drill faster than conventional bits, leading to significant time and cost savings in drilling operations.

- Reduced Drilling Costs: The increased drilling speed and longer bit life directly translate to reduced drilling costs.

- Improved Wellbore Quality: PDC bits create cleaner and smoother wellbores, reducing the risk of complications during completion and production.

Different Types of PDC:

PDC bits come in various designs and configurations to optimize performance based on specific geological conditions and drilling objectives. Some common types include:

- Tricone PDC Bits: They feature multiple cones with PDC inserts, providing superior cutting force and excellent penetration rates.

- Fixed Cutter PDC Bits: These bits use PDC cutters fixed to a metal matrix, offering exceptional wear resistance and durability.

- Jarring PDC Bits: Designed for challenging formations, these bits utilize a jarring mechanism to break through hard rock.

Conclusion:

PDC technology has revolutionized the drilling and well completion industry, offering significant advantages in terms of speed, efficiency, and cost reduction. Its exceptional hardness, durability, and performance make it an indispensable tool for navigating complex geological formations and maximizing resource recovery. As the industry continues to push the boundaries of exploration and development, PDC will remain a cornerstone of technological innovation in drilling and well completion.

Test Your Knowledge

PDC Quiz

Instructions: Choose the best answer for each question.

1. What does PDC stand for?

a) Polycrystalline Diamond Compact b) Pressure-Driven Cutting c) Polycarbonate Drill Component d) Precision Drilling Cutter

Answer

a) Polycrystalline Diamond Compact

2. Which of these is NOT a key advantage of using PDC bits?

a) Exceptional Hardness and Durability b) Increased Drilling Rates c) Reduced Drilling Costs d) Increased risk of wellbore complications

Answer

d) Increased risk of wellbore complications

3. Which type of PDC bit is designed for navigating complex formations and reaching targets off the vertical path?

a) Tricone PDC Bits b) Fixed Cutter PDC Bits c) Jarring PDC Bits d) Directional PDC Bits

Answer

d) Directional PDC Bits

4. PDC cutters are used in which of the following applications?

a) Rotary drilling only b) Well completion operations only c) Both rotary drilling and well completion operations d) None of the above

Answer

c) Both rotary drilling and well completion operations

5. Compared to conventional drill bits, PDC bits are:

a) Less expensive b) Less durable c) Slower drilling rates d) More efficient

Answer

d) More efficient

PDC Exercise

Scenario:

You are a drilling engineer tasked with choosing the best PDC bit for a new well in a challenging shale formation. The well will be drilled horizontally to access unconventional resources.

Task:

- Research different types of PDC bits (tricone, fixed cutter, jarring) and their advantages and disadvantages.

- Consider the specific challenges of drilling shale formations (abrasion, formation toughness).

- Based on your research, recommend the most suitable PDC bit type for this well and explain your reasoning.

Exercice Correction

The best PDC bit for drilling a horizontal well in a challenging shale formation is likely a **Fixed Cutter PDC Bit**. Here's why: * **Shale Formations:** Shale is notoriously abrasive and prone to causing wear and tear on drill bits. Fixed cutter bits offer superior wear resistance due to their fixed PDC cutters embedded in a metal matrix, making them ideal for handling harsh formations. * **Horizontal Drilling:** Horizontal wells require a bit that can maintain a stable trajectory and withstand the stresses of drilling in a lateral direction. Fixed cutter bits are known for their durability and stability, making them well-suited for horizontal drilling. * **Other Considerations:** While Tricone PDC bits can offer good penetration rates, they might be less effective in shale due to the possibility of premature wear on the cones. Jarring PDC bits are designed for extremely hard formations and may not be necessary for a typical shale environment. **Conclusion:** The fixed cutter PDC bit combines the advantages of high wear resistance, stability, and durability, making it the most appropriate choice for drilling a horizontal well in a shale formation.

Books

- "Drilling Engineering" by John A. Burgess and James S. Chiaramonte: This book provides a comprehensive overview of drilling operations, including a detailed section on PDC bit technology.

- "Well Completion Design and Operations" by John A. McLennan: This book focuses on well completion techniques and includes insights on PDC cutters used in various completion operations.

- "Drilling Fluids: Fundamentals and Applications" by John A. McLennan and Richard A. S. Fraser: This book covers drilling fluids and their impact on bit performance, including PDC bits.

Articles

- "Polycrystalline Diamond Compact (PDC) Cutters: An Overview" by SPE: This article provides a comprehensive overview of PDC cutter technology, its applications, and advantages.

- "Advances in PDC Bit Design for Challenging Formations" by IADC: This article explores recent advancements in PDC bit design, focusing on improvements for drilling through complex and abrasive formations.

- "Comparative Study of PDC and Steel Drill Bits for Hard Rock Drilling" by Journal of Petroleum Science and Engineering: This article presents a comparative analysis of PDC and steel drill bits in hard rock drilling, highlighting their advantages and limitations.

Online Resources

- SPE (Society of Petroleum Engineers): The SPE website offers a vast collection of technical papers, conference proceedings, and research reports related to PDC technology in drilling.

- IADC (International Association of Drilling Contractors): The IADC website provides resources and information on PDC bit design, selection, and application.

- Schlumberger: Schlumberger, a leading oilfield services company, offers comprehensive information on PDC bit technology, including product catalogs, technical specifications, and case studies.

- Baker Hughes: Baker Hughes, another leading oilfield services company, provides similar resources on PDC bit technology, emphasizing their specific offerings and innovations.

Search Tips

- Use specific keywords: "PDC drill bits," "PDC cutter technology," "PDC bit design," "PDC bit applications," "PDC bit performance," "PDC bit selection."

- Combine keywords with industry terms: "PDC bit for shale formations," "PDC bit for horizontal drilling," "PDC bit for well completion."

- Include specific drilling parameters: "PDC bit for high-pressure, high-temperature conditions," "PDC bit for high-angle wells," "PDC bit for deepwater drilling."

- Explore scientific journals: "PDC bit research," "PDC bit advancements," "PDC bit patents."

Techniques

PDC: The Cutting Edge in Drilling & Well Completion

Chapter 1: Techniques

The application of PDC technology involves specific techniques optimized for various geological formations and drilling objectives. The success of a PDC operation hinges on understanding and properly implementing these techniques.

Selection of PDC Bits: Choosing the right PDC bit is paramount. This involves considering factors like:

- Formation type: Hard, abrasive formations require bits with robust PDC inserts and a durable matrix. Softer formations might benefit from bits with a different insert configuration.

- Drilling parameters: Weight on bit (WOB), rotational speed (RPM), and flow rate all impact bit performance and must be optimized. Incorrect parameters can lead to premature wear or inefficient drilling.

- Wellbore trajectory: Vertical, directional, or horizontal wells require different bit designs to maintain stability and optimal penetration rates.

Drilling Optimization: Achieving maximum efficiency requires real-time monitoring and adjustments. Key parameters to monitor and adjust include:

- Torque and drag: High torque and drag indicate potential problems like bit balling or sticking. Adjustments to WOB, RPM, or mud properties might be necessary.

- Rate of penetration (ROP): Continuously monitoring ROP helps identify optimal drilling parameters and allows for proactive adjustments to maintain efficiency.

- Vibration and shock: Excessive vibration indicates potential problems with bit stability or formation interaction. Adjustments to drilling parameters or bit selection might be needed.

Advanced Techniques: Modern PDC drilling incorporates advanced techniques to further enhance efficiency and performance:

- Managed Pressure Drilling (MPD): MPD utilizes precise pressure control to prevent formation kicks and optimize wellbore stability, especially beneficial in challenging formations.

- Rotary Steerable Systems (RSS): RSS allows for precise directional control, enabling efficient drilling of complex wellbores. PDC bits are ideally suited for use with RSS.

- Real-time data acquisition and analysis: Sophisticated sensors and data analysis software provide valuable insights into bit performance, allowing for real-time optimization.

Chapter 2: Models

Predictive modeling plays a crucial role in optimizing PDC drilling operations. Several models are employed to anticipate performance and minimize risks.

Bit Life Prediction Models: These models estimate the expected lifespan of a PDC bit based on factors like formation properties, drilling parameters, and bit design. Accurate predictions help optimize bit selection and reduce non-productive time (NPT).

ROP Prediction Models: These models estimate the anticipated rate of penetration based on formation properties, drilling parameters, and bit design. Accurate predictions help optimize drilling parameters and plan efficient drilling operations.

Mechanical and Thermal Models: These complex models simulate the interactions between the PDC bit, the formation, and the drilling fluid. They help predict bit wear, thermal stresses, and potential failure modes, contributing to improved bit design and drilling optimization.

Empirical Models: Simpler empirical models, based on historical data, are often used for quick estimations of ROP and bit life. They are useful for initial planning but may lack the accuracy of more complex models.

Chapter 3: Software

Specialized software plays a critical role in PDC drilling operations, from planning and simulation to real-time monitoring and data analysis.

Drilling Simulation Software: This software allows engineers to simulate different drilling scenarios, optimizing drilling parameters and predicting bit performance before commencing operations.

Data Acquisition and Monitoring Software: Real-time data acquisition systems, coupled with sophisticated software, provide continuous monitoring of key parameters such as ROP, torque, drag, and vibration. This data allows for real-time adjustments and optimization of the drilling process.

Wellbore Trajectory Planning Software: This software enables precise planning of wellbore trajectories, taking into account formation properties, geological constraints, and drilling limitations.

Data Analysis and Interpretation Software: This software helps analyze large datasets acquired during drilling operations, identifying trends, anomalies, and potential problems. This information is crucial for optimizing future drilling operations.

Chapter 4: Best Practices

Adhering to best practices is crucial for maximizing the efficiency and longevity of PDC drilling operations.

Pre-Drilling Planning: Thorough pre-drilling planning, including geological surveys, formation analysis, and selection of appropriate PDC bits and drilling parameters, is essential for success.

Proper Mud Selection: Selecting the right drilling mud is vital for maintaining wellbore stability, optimizing ROP, and minimizing bit wear.

Regular Bit Inspections: Regular inspections of the PDC bit during drilling operations help identify potential problems early on, preventing catastrophic failures and reducing NPT.

Data Logging and Analysis: Continuous logging and analysis of drilling data is crucial for optimizing drilling parameters and improving future operations.

Safety Procedures: Adherence to strict safety procedures is essential to prevent accidents and protect personnel and equipment.

Chapter 5: Case Studies

Several case studies highlight the successful application of PDC technology in diverse geological settings and drilling scenarios.

(Example Case Study 1): A case study detailing the use of PDC bits in drilling a horizontal well through a challenging shale formation, showcasing the improved ROP and reduced drilling costs compared to conventional bits. Quantifiable data like ROP increase percentage, cost savings, and reduced NPT should be included.

(Example Case Study 2): A case study demonstrating the application of PDC bits in a deepwater drilling operation, highlighting the importance of bit selection and drilling optimization for maximizing efficiency in a harsh environment. The challenges faced (high pressure, temperature) and how PDC technology overcame them should be detailed.

(Example Case Study 3): A comparison of different PDC bit designs in a specific formation, demonstrating the impact of bit design on ROP, bit life, and overall drilling efficiency.

Each case study should include details on the specific geological conditions, the PDC technology employed, the results achieved, and the lessons learned. Quantifiable data should be included to support the conclusions drawn. This section would need to be populated with real-world examples.

- PDC bit PDC Bits: Revolutionizing…

- PDC Log PDC Log: Guiding the Bullet t…

- perforation depth control log (PDC log) Pinpointing Perforation Depth…

- polycrystalline diamond compact (PDC) The Cutting Edge of Oil & Gas…

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments