Oil & Gas Processing

Hydrocyclone

Hydrocyclones: The Whirlwind of Separation in Oil & Gas

Hydrocyclones, also known as cyclones, are versatile pieces of equipment used extensively in the oil and gas industry. They are essentially cone-shaped devices that leverage centrifugal force to separate fluids and the solid particles dispersed within them. This separation process is crucial for various operations, including:

1. Sand Removal:

Hydrocyclones are essential for removing sand and other solid particles from produced fluids (oil, gas, and water) before they reach downstream processing equipment. These solids can cause abrasion, blockage, and even damage to valuable equipment. By spinning the fluid rapidly, the heavier sand particles are flung outwards and settle at the bottom of the cone, while the lighter fluids are discharged from the top.

2. Desanding:

Desanding is a crucial step in treating produced water before it can be safely discharged or reused. Hydrocyclones effectively remove sand, silt, and other solids from the water, reducing the risk of clogging and improving the overall quality of the water.

3. Dehydration:

Hydrocyclones can be used to separate water from oil and gas, thereby reducing the water content in the produced fluids. This process, known as dehydration, is essential for optimizing the efficiency of downstream processing and maximizing the value of the extracted hydrocarbons.

4. Solids Removal from Drilling Fluids:

Drilling fluids, used to lubricate and cool drill bits, can become contaminated with solids during drilling operations. Hydrocyclones effectively remove these solids, ensuring the efficient and safe operation of the drilling process.

How It Works:

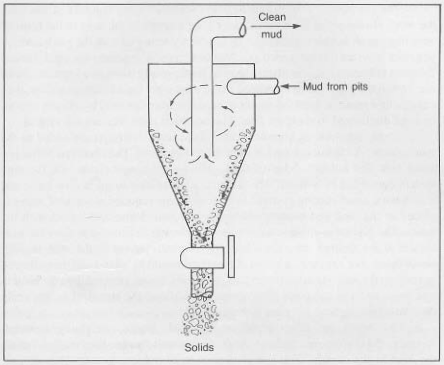

The principle behind hydrocyclone operation is simple yet effective:

- Tangential Feed: The fluid mixture enters the hydrocyclone tangentially, creating a swirling, vortex-like motion.

- Centrifugal Force: As the fluid spins, centrifugal force pulls the heavier solids towards the outside of the cone.

- Separation: The heavier solids settle at the bottom of the cone and are discharged as a concentrated stream, while the lighter fluids are discharged from the top.

Advantages of Hydrocyclones:

- Simplicity and Low Maintenance: Hydrocyclones are relatively simple in design and have minimal moving parts, requiring minimal maintenance.

- Efficiency: They can achieve high separation efficiencies, effectively removing even small solid particles.

- Cost-Effectiveness: Compared to other separation technologies, hydrocyclones are often more cost-effective in terms of initial investment and operating costs.

- Versatility: Hydrocyclones can be used for a wide range of applications, including different fluid types and solid particle sizes.

Conclusion:

Hydrocyclones are vital tools in the oil and gas industry, playing a critical role in various operations, from sand removal to dehydration. Their simple design, high efficiency, and cost-effectiveness make them essential for maintaining the smooth and reliable operation of oil and gas facilities, ultimately contributing to the efficient and safe production of valuable resources.

Test Your Knowledge

Hydrocyclone Quiz

Instructions: Choose the best answer for each question.

1. What is the primary function of a hydrocyclone?

a) To mix fluids and solids b) To separate fluids and solids c) To heat fluids d) To cool fluids

Answer

b) To separate fluids and solids

2. Which of the following is NOT a common application of hydrocyclones in the oil and gas industry?

a) Sand removal b) Desanding c) Dehydration d) Water injection

Answer

d) Water injection

3. What force is primarily responsible for the separation process in a hydrocyclone?

a) Gravity b) Magnetic force c) Centrifugal force d) Electrostatic force

Answer

c) Centrifugal force

4. Which of the following is an advantage of using hydrocyclones?

a) High maintenance requirements b) Low separation efficiency c) High capital investment costs d) Simplicity and low maintenance

Answer

d) Simplicity and low maintenance

5. How does the fluid enter a hydrocyclone?

a) From the bottom, vertically b) From the top, vertically c) Tangentially, creating a swirl d) Horizontally, without any swirl

Answer

c) Tangentially, creating a swirl

Hydrocyclone Exercise

Scenario: You are working on a drilling rig and the drilling mud is becoming too thick due to excessive solid particles. A hydrocyclone is used to remove these solids. Explain how the hydrocyclone would work in this scenario to improve the drilling fluid.

Exercice Correction

The drilling mud is pumped into the hydrocyclone tangentially, creating a swirling motion. This swirling motion generates centrifugal force, which pushes the heavier solid particles outwards towards the wall of the cone. These solids then settle at the bottom of the cone and are discharged as a concentrated stream, known as the underflow. The lighter, cleaner drilling fluid exits the top of the cone, known as the overflow, and is recirculated back into the drilling system. This process effectively removes the excess solids from the drilling mud, reducing its viscosity and improving its ability to lubricate and cool the drill bit.

Books

- "Hydrocyclones: Principles and Applications" by G. T. Gillespie and J. D. Wilson: This comprehensive book provides a detailed overview of hydrocyclone theory, design, and applications in various industries, including oil and gas.

- "Separation Technology in the Oil and Gas Industry" edited by A. L. Kohl and R. Nielsen: This volume includes a chapter on hydrocyclones, discussing their application in oil and gas processing.

- "Handbook of Separation Techniques for Chemical Engineers" edited by P. A. Schweitzer: Contains a chapter on centrifugal separators, which covers the principles of hydrocyclones and their use in various industries.

Articles

- "Hydrocyclones: A Powerful Tool for Sand Removal in Oil and Gas Production" by J. P. Smith: Provides a practical overview of hydrocyclone application in sand removal, covering design considerations and performance optimization.

- "Hydrocyclone Performance in Oilfield Applications: A Review" by M. J. Brown: This review article analyzes the efficiency and limitations of hydrocyclones in various oilfield applications, including desanding and dehydration.

- "The Use of Hydrocyclones for Desanding in Oil and Gas Production" by K. L. Jones: Discusses the specific challenges and solutions related to desanding in oil and gas production using hydrocyclones.

- "Hydrocyclones for Solids Removal from Drilling Fluids" by R. T. Davis: Examines the role of hydrocyclones in removing solids from drilling fluids, highlighting their impact on drilling efficiency and wellbore stability.

Online Resources

- "Hydrocyclones" on Wikipedia: Provides a basic overview of hydrocyclones, covering their history, principles, and applications.

- "Hydrocyclones" on the website of the American Society of Mechanical Engineers (ASME): Offers technical resources and information on hydrocyclone design and operation, including industry standards.

- "Hydrocyclones in the Oil and Gas Industry" by Schlumberger: Provides a case study highlighting the successful use of hydrocyclones for sand removal in oil and gas production.

Search Tips

- Use specific keywords: "hydrocyclones oil and gas", "hydrocyclones sand removal", "hydrocyclones desanding", "hydrocyclones drilling fluids"

- Use quotation marks for specific phrases: "hydrocyclone efficiency"

- Combine keywords with industry names: "hydrocyclones in oil and gas industry"

- Use site: operator to target specific websites: "site:slb.com hydrocyclones"

Techniques

Hydrocyclones in Oil & Gas: A Comprehensive Guide

This guide breaks down the crucial aspects of hydrocyclones in the oil and gas industry, covering techniques, models, software, best practices, and case studies.

Chapter 1: Techniques

The effectiveness of a hydrocyclone hinges on understanding and optimizing several key techniques:

Tangential Inlet Design: The angle and geometry of the tangential inlet significantly influence the vortex formation and separation efficiency. Precise design is crucial for maximizing centrifugal force and minimizing pressure loss. Variations include single-inlet, multiple-inlet, and spiral-inlet designs, each with its own advantages depending on the application and particle size distribution.

Vortex Finder and Apex Design: The shape and size of the vortex finder (the central tube) controls the overflow rate of the clarified fluid. The apex design influences the underflow concentration and discharge. Optimizing these elements is key to achieving the desired separation sharpness.

Underflow and Overflow Discharge Configurations: The design and placement of the underflow and overflow discharge points affect the separation efficiency and pressure drop. Precise control over these parameters is crucial to avoid recirculation and maintain the desired separation. Techniques like using adjustable spouts or vortex breakers can enhance separation.

Pressure Control and Optimization: The inlet pressure significantly impacts the centrifugal force and consequently, the separation efficiency. Optimizing pressure is critical and often involves balancing efficiency against energy consumption. Techniques like pressure regulation valves and monitoring systems help achieve this.

Chapter 2: Models

Various hydrocyclone models exist, each tailored to specific applications and fluid characteristics:

Conventional Hydrocyclones: These are the most common type, characterized by their simple conical shape and relatively low pressure drop. They are effective for a wide range of applications but may not be optimal for very fine particle separation.

High-efficiency Hydrocyclones: These designs incorporate features like optimized vortex finders and improved inlet geometries to achieve higher separation efficiencies, especially for finer particles. They often have higher pressure drops than conventional designs.

Multi-stage Hydrocyclones: These systems connect multiple hydrocyclones in series, increasing the overall separation efficiency. Each stage handles a specific particle size range, improving the overall removal of solids.

Specialized Hydrocyclones: Specialized designs cater to specific needs, such as those used for high-viscosity fluids or those incorporating magnetic fields for enhanced separation of magnetic particles.

Chapter 3: Software

Computational Fluid Dynamics (CFD) software plays a vital role in hydrocyclone design and optimization:

CFD Simulation: Software such as ANSYS Fluent, COMSOL Multiphysics, and OpenFOAM allow engineers to simulate the fluid flow and particle separation within a hydrocyclone. This helps optimize design parameters and predict performance before physical construction.

Particle Tracking: Specialized modules within CFD software track the movement of individual particles, enabling accurate prediction of separation efficiency and particle size distribution in the underflow and overflow streams.

Optimization Algorithms: These tools automate the design optimization process, exploring different design parameters to identify the optimal configuration based on specified performance criteria.

Chapter 4: Best Practices

Effective hydrocyclone operation requires adherence to best practices:

Regular Inspection and Maintenance: Regular inspections are essential to identify and address potential issues like wear and tear, blockages, or leaks, ensuring continuous optimal performance. Preventive maintenance schedules should be implemented.

Feed Preparation: Proper preparation of the feed stream is crucial. This involves pre-screening to remove oversized particles that could damage the hydrocyclone and ensuring a consistent feed flow rate to maintain optimal separation.

Monitoring and Control: Continuous monitoring of key parameters like pressure, flow rate, and underflow/overflow concentrations allows for early detection of operational problems and enables timely adjustments.

Proper Material Selection: Selecting appropriate materials based on the corrosive nature of the fluids and the abrasive nature of the solids is vital to ensure the longevity of the hydrocyclone.

Chapter 5: Case Studies

Real-world examples demonstrate the versatility and effectiveness of hydrocyclones:

Case Study 1: Sand Removal from Produced Water: A case study could detail a specific oil and gas production facility where hydrocyclones were implemented to effectively remove sand from produced water, reducing downstream equipment wear and improving water discharge quality. Quantifiable results like percentage of sand removed and cost savings would be included.

Case Study 2: Dehydration of Crude Oil: Another case study could focus on the use of hydrocyclones for dehydrating crude oil, illustrating how these devices improved the efficiency of downstream processing and minimized the water content in the final product. Performance metrics such as water content reduction and throughput would be highlighted.

Case Study 3: Solids Removal from Drilling Fluids: A case study focusing on drilling operations would show how hydrocyclones significantly reduced solids content in drilling fluids, maintaining drilling efficiency and reducing the need for frequent fluid replacement. Metrics like reduced downtime and improved drilling rate could be presented.

This comprehensive guide offers a detailed understanding of hydrocyclones and their application in the oil and gas industry. By understanding the techniques, models, software, best practices, and case studies presented, engineers and operators can optimize their use and maximize efficiency.

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments