Pipeline Construction

Funnel Viscosity

Funnel Viscosity: A Simple, Practical Approach to Viscosity Measurement

In the world of materials science and engineering, understanding the viscosity of fluids is crucial. Viscosity, a measure of a fluid's resistance to flow, plays a significant role in numerous applications, from manufacturing processes to food production. While sophisticated techniques like rotational viscometry exist, a simpler, more practical method is often employed: Funnel Viscosity.

What is Funnel Viscosity?

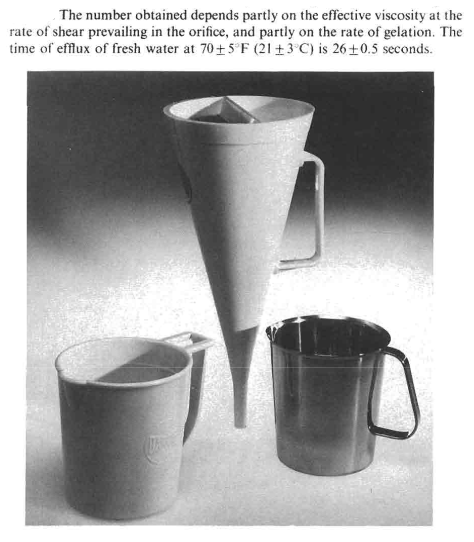

Funnel viscosity, also known as Marsh funnel viscosity, is a measurement that quantifies the time it takes for a specific volume (typically 1 liter) of fluid to flow through a standardized funnel known as the Marsh funnel.

How Does it Work?

The Marsh funnel, a cone-shaped vessel with a specific orifice size, is filled with the fluid. The time taken for the fluid to drain through the orifice is recorded. This time, measured in seconds, is the funnel viscosity. A longer time indicates higher viscosity, meaning the fluid is more resistant to flow.

Key Features of Funnel Viscosity:

- Simplicity: The method is straightforward, requiring minimal equipment and expertise.

- Low Cost: Marsh funnels are inexpensive and readily available.

- Practicality: Ideal for quick, on-site viscosity checks, particularly in industrial settings.

- Relativity: Funnel viscosity provides a relative measure, useful for comparing different batches or grades of the same fluid.

Limitations of Funnel Viscosity:

- Limited Accuracy: The method is less accurate than other techniques like rotational viscometry.

- Influence of Factors: Factors like fluid temperature, pressure, and funnel size can affect the measurement.

- Non-Standardisation: Different funnel sizes exist, making comparisons between measurements obtained using different funnels challenging.

Applications of Funnel Viscosity:

Funnel viscosity is widely used in various industries, including:

- Paints and Coatings: Monitoring the viscosity of paints and coatings to ensure proper application and drying.

- Food Processing: Controlling the viscosity of sauces, syrups, and other food products.

- Petroleum: Evaluating the viscosity of crude oil and other petroleum products.

- Construction: Monitoring the consistency of concrete mixes.

In Conclusion:

Funnel viscosity, despite its limitations, remains a valuable tool for rapid, practical viscosity assessment in diverse settings. Its simplicity, affordability, and ease of use make it a reliable method for quality control and consistency monitoring in numerous applications. However, it's essential to recognize its limitations and use it in conjunction with other, more precise techniques when high accuracy is required.

Test Your Knowledge

Funnel Viscosity Quiz:

Instructions: Choose the best answer for each question.

1. What is the primary purpose of using a Marsh funnel in viscosity measurement?

a) To heat the fluid before measurement. b) To precisely measure the volume of the fluid. c) To determine the time it takes for a specific volume of fluid to flow through the funnel. d) To filter impurities from the fluid.

Answer

c) To determine the time it takes for a specific volume of fluid to flow through the funnel.

2. Which of the following is NOT a key feature of funnel viscosity measurement?

a) Simplicity b) Low cost c) High accuracy d) Practicality

Answer

c) High accuracy

3. In what industry is funnel viscosity commonly used to monitor the consistency of concrete mixes?

a) Food processing b) Construction c) Petroleum d) Paints and coatings

Answer

b) Construction

4. What does a longer funnel viscosity time indicate about the fluid?

a) The fluid is less viscous. b) The fluid is more viscous. c) The fluid is at a higher temperature. d) The fluid is at a lower pressure.

Answer

b) The fluid is more viscous.

5. What is a significant limitation of funnel viscosity measurement?

a) It requires expensive equipment. b) It is not suitable for industrial applications. c) It is highly sensitive to changes in temperature and pressure. d) It is less accurate than other viscosity measurement methods.

Answer

d) It is less accurate than other viscosity measurement methods.

Funnel Viscosity Exercise:

Instructions:

Imagine you are a quality control inspector at a paint manufacturing company. You need to ensure that all batches of paint have a consistent viscosity. You use a Marsh funnel to measure the viscosity of a new batch of paint. The time it takes for 1 liter of paint to flow through the funnel is 45 seconds.

1. What is the funnel viscosity of this batch of paint?

2. You compare this measurement to the previous batch of paint, which had a funnel viscosity of 50 seconds. What can you conclude about the viscosity of the new batch of paint compared to the previous batch?

3. Explain why it is important to maintain consistent viscosity in paint production.

Exercise Correction

**1. The funnel viscosity of the new batch of paint is 45 seconds.**

**2. The new batch of paint has a lower viscosity than the previous batch.** This is because it took less time for the paint to flow through the funnel.

**3. Maintaining consistent viscosity in paint production is crucial for several reasons:**

- **Even application:** A consistent viscosity ensures the paint applies evenly and smoothly to surfaces, avoiding streaks or uneven coverage.

- **Drying time:** Viscosity impacts how quickly the paint dries. Consistent viscosity helps maintain predictable drying times and prevents uneven drying.

- **Durability:** The viscosity of the paint affects its final durability. Consistent viscosity helps ensure a strong, long-lasting coating.

Books

- "Viscosity and Rheology" by H.A. Barnes (1995) - Comprehensive overview of viscosity, including a section on funnel viscosity.

- "Practical Rheology: A Guide to Measuring Viscosity and Flow Properties" by K. Walters (1996) - Provides a practical guide to viscosity measurement techniques, including funnel viscosity.

- "Fluid Mechanics" by F.M. White (2006) - A standard textbook on fluid mechanics that touches upon the concept of viscosity and its measurement.

Articles

- "Funnel Viscosity: A Simple, Practical Approach to Viscosity Measurement" by [Your Name] (2023) - This article itself! Provides a basic introduction to funnel viscosity.

- "Determination of Funnel Viscosity" by ASTM International (D2196-11) - A standard test method for funnel viscosity determination.

- "A Comparison of Funnel Viscosity and Rotational Viscometry for Measuring the Viscosity of Paint" by J.M. Smith et al. (2010) - A study comparing funnel viscosity with a more accurate method, highlighting its limitations.

Online Resources

- ASTM International: https://www.astm.org/ - Offers standards and resources for various materials testing, including viscosity measurement.

- Wikipedia: https://en.wikipedia.org/wiki/Viscosity - A comprehensive overview of viscosity, its measurement, and applications.

- Viscometer Manufacturers: Check websites of viscometer manufacturers (e.g., Brookfield, Anton Paar) for technical information on viscosity measurement and related topics.

Search Tips

- "Funnel Viscosity ASTM": This will return relevant ASTM standards related to funnel viscosity measurement.

- "Marsh Funnel Viscosity": This will provide results specific to the Marsh funnel and its application.

- "Funnel Viscosity vs. Rotational Viscometry": This search will help you find resources comparing the two techniques.

Techniques

Funnel Viscosity: A Detailed Exploration

This document expands on the concept of funnel viscosity, breaking it down into specific chapters for clarity and detailed understanding.

Chapter 1: Techniques

Funnel viscosity measurement relies on a simple yet effective technique: measuring the flow time of a fluid through a standardized funnel. The most common type is the Marsh funnel, characterized by a specific cone angle and orifice diameter. The standard procedure involves:

Preparation: Ensure the funnel is clean and dry. The fluid should be at a controlled and consistent temperature, as temperature significantly impacts viscosity. Pre-heating or cooling may be necessary.

Filling: Fill the funnel completely to the designated fill line, avoiding air bubbles. Gentle tapping may be necessary to remove trapped air.

Timing: Start the timer precisely the moment the fluid begins to flow from the orifice. Stop the timer when the specified volume (usually 1 liter) has completely drained.

Recording: Record the flow time in seconds. This time represents the funnel viscosity. Multiple measurements should be taken and averaged to improve accuracy and account for variations.

Cleaning: Thoroughly clean the funnel after each measurement to prevent cross-contamination.

Variations exist in funnel design, including the size of the orifice and the overall cone angle. These variations necessitate specifying the exact funnel type used when reporting results, as direct comparison between measurements from different funnels is problematic. Some less common techniques might involve using different funnel shapes or even simple, improvised funnels for quick, less-precise assessments.

Chapter 2: Models

While funnel viscosity doesn't rely on a complex mathematical model like rotational viscometry, understanding the underlying physics helps interpret the results. The flow through the funnel is governed by factors including:

- Gravity: The driving force for fluid flow.

- Fluid viscosity: The resistance to flow, directly related to the flow time.

- Funnel geometry: The cone angle and orifice diameter significantly affect the flow rate.

- Fluid density: A denser fluid will flow slightly faster due to increased gravitational force.

- Surface tension: Can influence the initial flow behavior, particularly for low-viscosity fluids.

A simplified model can be expressed as a relationship between flow time (t) and viscosity (η): t ∝ η. This proportionality suggests that flow time increases linearly with viscosity, although this is an approximation and doesn't account for all the variables involved. More sophisticated models incorporating the various factors listed above would require extensive empirical calibration and are rarely used in practice due to the inherent simplicity of the method.

Chapter 3: Software

Specialized software is rarely used for funnel viscosity measurements. The process is manual, primarily involving timing the flow and recording the result. However, spreadsheet software (like Microsoft Excel or Google Sheets) can be useful for:

- Data logging: Recording multiple measurements, averaging the results, and calculating standard deviations.

- Data analysis: Comparing viscosity values from different batches or samples.

- Data visualization: Creating graphs and charts to illustrate trends in viscosity.

More advanced statistical software packages could be used for more in-depth analysis if multiple factors (temperature, pressure, etc.) are being controlled and studied simultaneously. However, for typical funnel viscosity applications, basic spreadsheet functionalities are sufficient.

Chapter 4: Best Practices

To ensure reliable and consistent funnel viscosity measurements, adhere to these best practices:

- Temperature control: Maintain a constant temperature throughout the measurement process.

- Cleanliness: Clean the funnel thoroughly before and after each measurement to prevent contamination.

- Consistent filling: Fill the funnel to the designated mark consistently to ensure a repeatable starting volume.

- Multiple measurements: Take several measurements and average the results to minimize errors.

- Appropriate funnel selection: Select a funnel appropriate for the viscosity range of the fluid being measured.

- Calibration: Periodically check the funnel for any damage or wear that might affect the accuracy.

- Documentation: Record all relevant details, including the funnel type, temperature, and the number of measurements.

Chapter 5: Case Studies

Case Study 1: Paint Viscosity Control: A paint manufacturer uses funnel viscosity to quickly assess the viscosity of different paint batches during production. Consistent funnel viscosity readings ensure the paint maintains the desired application properties. Deviations from the target flow time trigger adjustments to the paint formulation.

Case Study 2: Concrete Mix Consistency: A construction company uses funnel viscosity to monitor the consistency of concrete mixes on-site. The flow time helps ensure the concrete is workable and meets the required specifications. A significantly shorter or longer flow time might indicate problems with the mix proportions or water content.

Case Study 3: Food Product Quality Control: A food processing plant uses funnel viscosity to control the viscosity of sauces and syrups. Regular checks ensure the products maintain the desired consistency and flow characteristics. Changes in funnel viscosity can trigger adjustments to the processing parameters or ingredient ratios.

These case studies illustrate how funnel viscosity provides a simple yet effective way to monitor and control the viscosity of various materials in different industries. While less precise than other techniques, its simplicity and low cost make it a practical tool for rapid, on-site quality control.

- Drain funnel Drain Funnels: The Unsung Her…

- Kinematic Viscosity Kinematic Viscosity: A Key Pa…

- Dynamic Viscosity (produced fluid) Understanding Dynamic Viscosi…

- K (viscosity) Understanding K-Factor: A Key…

- Marsh Funnel Understanding the Marsh Funne…

- n (viscosity) Understanding Viscosity and i…

- Plastic Viscosity Plastic Viscosity: Understand…

- Shear Stress (viscosity) Shear Stress: A Crucial Force…

- Viscosity Viscosity: A Sticky Subject i…

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments