Reliability Engineering

Fatigue Strength

Fatigue Strength: The Endurance of Materials Under Repetitive Stress

In the world of engineering, materials are subjected to a wide range of stresses. While a single, high-stress event might be catastrophic, repetitive stress, even at lower magnitudes, can lead to unexpected and often devastating failures. This phenomenon is known as fatigue, and fatigue strength is a crucial measure of a material's ability to withstand such cyclic loading.

Understanding Fatigue Strength:

Imagine a piece of metal being bent back and forth repeatedly. With each bend, tiny cracks begin to form and grow within the material. Over time, these microscopic fractures coalesce, leading to a catastrophic failure, even though the applied stress is significantly lower than the material's ultimate tensile strength.

Fatigue strength quantifies the maximum stress a material can withstand for a specified number of cycles without failing. It is typically expressed as a stress amplitude, represented by the symbol σa, and is measured in units of stress (e.g., MPa, psi).

Key Factors Influencing Fatigue Strength:

Several factors play a crucial role in determining a material's fatigue strength:

- Material Properties: The inherent properties of the material, such as its microstructure, hardness, and ductility, greatly influence its fatigue resistance.

- Stress Amplitude and Mean Stress: The magnitude of the stress fluctuations and the average stress level during cycling directly impact fatigue life. Higher stress amplitudes and mean stresses generally lead to shorter fatigue lives.

- Stress Concentration: Sharp corners, holes, or other geometric irregularities in a component can concentrate stress, significantly reducing fatigue strength.

- Environmental Conditions: Temperature, humidity, and corrosive environments can accelerate fatigue crack growth, decreasing fatigue life.

- Surface Finish: A smooth surface reduces the likelihood of stress concentration, improving fatigue strength.

- Loading Frequency: The rate at which the load is applied can affect fatigue behavior. Higher frequencies can lead to increased fatigue damage.

S-N Curve: Visualizing Fatigue Life:

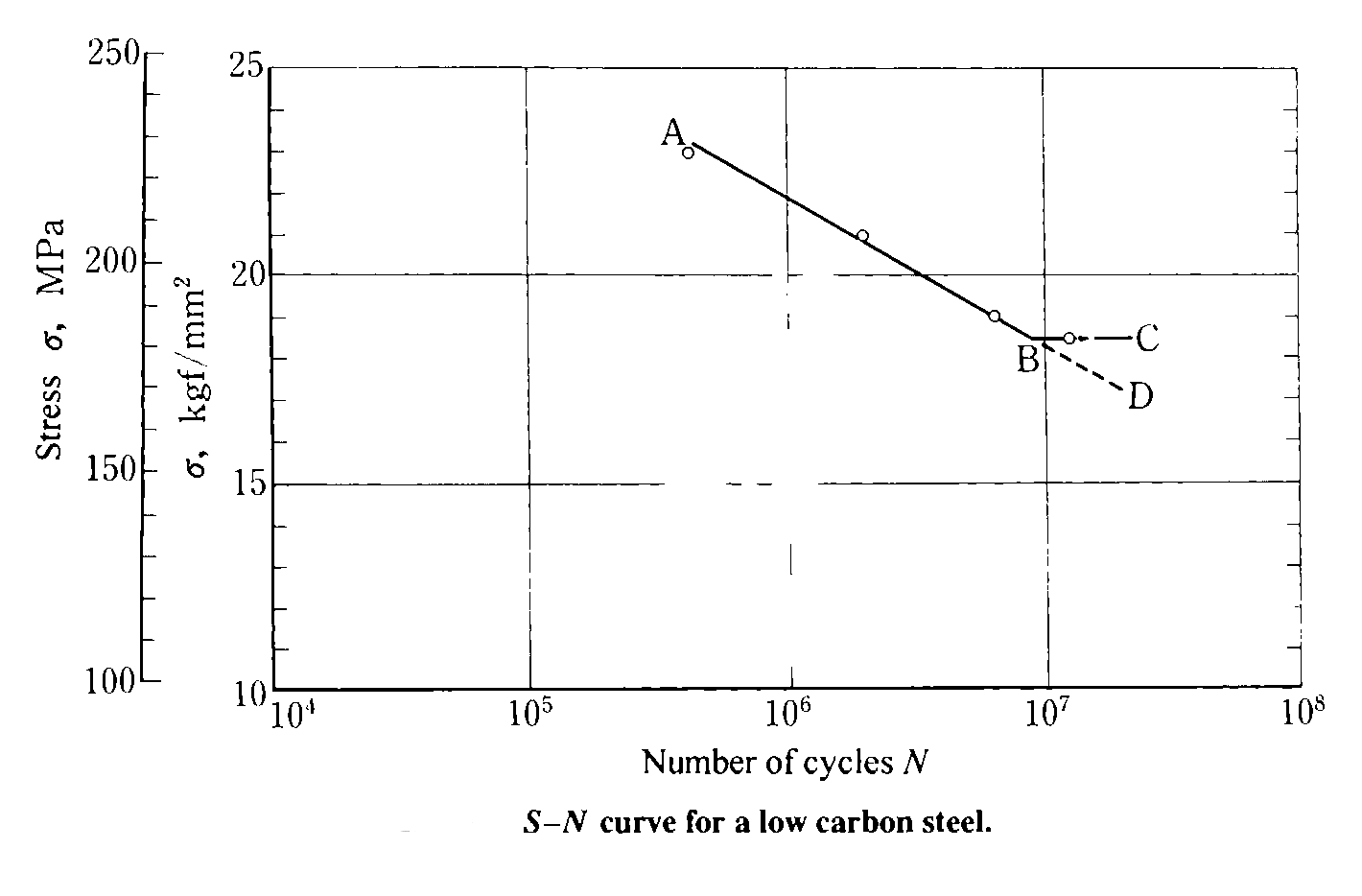

The relationship between stress amplitude and fatigue life is often represented graphically using an S-N curve. This curve plots the stress amplitude (σa) against the number of cycles to failure (N). The S-N curve helps engineers predict the fatigue life of a component based on the expected stress levels and loading conditions.

Applications of Fatigue Strength:

Fatigue strength is a critical consideration in many engineering applications, particularly those involving:

- Aircraft and aerospace components: Subject to repeated loading during flight and landing.

- Automotive parts: Exposed to vibrations and repetitive stresses from engine operation.

- Bridges and structures: Designed to withstand cyclic loads from traffic and wind.

- Medical implants: Require long-term durability under physiological stresses.

Conclusion:

Fatigue strength is an essential parameter for ensuring the safety and reliability of structures and components under cyclic loading. By understanding the factors influencing fatigue strength and employing appropriate design practices, engineers can mitigate fatigue failure risks and extend the lifespan of various engineered systems.

Test Your Knowledge

Fatigue Strength Quiz

Instructions: Choose the best answer for each question.

1. What is the primary cause of fatigue failure in materials? a) A single, high-stress event b) Repetitive stress at lower magnitudes c) Chemical corrosion d) Temperature fluctuations

Answer

b) Repetitive stress at lower magnitudes

2. What does fatigue strength quantify? a) The maximum stress a material can withstand before permanent deformation b) The maximum stress a material can withstand for a specified number of cycles without failing c) The rate at which a material will corrode under cyclic loading d) The amount of energy a material can absorb before fracturing

Answer

b) The maximum stress a material can withstand for a specified number of cycles without failing

3. Which of the following factors does NOT influence fatigue strength? a) Material properties b) Stress amplitude and mean stress c) Ambient lighting conditions d) Stress concentration

Answer

c) Ambient lighting conditions

4. What is an S-N curve used for? a) Predicting the fatigue life of a component based on stress levels and loading conditions b) Determining the ultimate tensile strength of a material c) Measuring the rate of corrosion in a material d) Calculating the amount of energy absorbed by a material during impact

Answer

a) Predicting the fatigue life of a component based on stress levels and loading conditions

5. Which of the following applications is NOT significantly affected by fatigue strength? a) Aircraft wings b) Building foundations c) Medical implants d) Electrical wiring

Answer

d) Electrical wiring

Fatigue Strength Exercise

Scenario: A steel bridge is being designed to withstand the weight of heavy trucks passing over it. The expected stress amplitude experienced by the bridge's main support beams is 100 MPa. Using the S-N curve provided below, estimate the fatigue life of the support beams.

S-N Curve:

Exercise Correction:

Exercise Correction

To estimate the fatigue life, locate the stress amplitude of 100 MPa on the y-axis of the S-N curve. Then, draw a horizontal line from that point until it intersects the S-N curve. From the point of intersection, draw a vertical line down to the x-axis. This intersection point on the x-axis represents the estimated fatigue life in cycles. **Note:** The exact fatigue life will depend on the specific S-N curve provided and the units of the x-axis.

Books

- "Fatigue of Materials" by J.A. Bannantine, J.J. Comer, and J.L. Handrock (This is a classic textbook covering a wide range of topics on fatigue).

- "Fatigue Design" by D.A. Crandall and N.C. Dahl (Provides a practical approach to fatigue analysis and design).

- "Fundamentals of Fatigue" by C. Laird (An introductory text focusing on the basic principles of fatigue).

- "Fatigue and Fracture Mechanics" by S. Suresh (A comprehensive treatment of fatigue and fracture mechanics).

- "Fatigue and Durability" by S.H. Wang (Offers a detailed analysis of fatigue and durability considerations in structural design).

Articles

- "Fatigue Crack Growth" by Paris and Erdogan (A seminal paper on fatigue crack growth).

- "A Unified Approach to Fatigue Crack Growth" by Elber (Introduces the concept of crack closure in fatigue).

- "Fatigue Life Prediction Methods: A Review" by Suresh and Ritchie (Provides an overview of various fatigue life prediction methods).

- "Fatigue Damage Accumulation: A Review" by Langer (Discusses the concept of fatigue damage accumulation).

Online Resources

- ASM International - Fatigue and Fracture: https://www.asminternational.org/web/ (ASM International provides comprehensive information on fatigue and fracture).

- National Institute of Standards and Technology (NIST) Fatigue Website: https://www.nist.gov/ (NIST offers valuable resources on fatigue testing and analysis).

- Fatigue Analysis Software: Several software packages are available for fatigue analysis, such as ANSYS, ABAQUS, and FE-SAFE.

Search Tips

- "Fatigue Strength" "Material Name": For specific materials, like "Fatigue Strength Aluminum".

- "Fatigue Testing Standards": For information on relevant testing standards, like ASTM or ISO.

- "Fatigue Life Prediction": To learn about methods for estimating fatigue life.

- "Fatigue Crack Growth Rate": For information on crack propagation during fatigue.

Techniques

Chapter 1: Techniques for Fatigue Strength Evaluation

This chapter delves into the methods employed to assess the fatigue strength of materials and components. These techniques are essential for understanding the material's response to cyclic loading and predicting its fatigue life.

1.1 Experimental Techniques

Fatigue Testing: This involves subjecting a specimen to controlled cyclic loading and monitoring its response until failure. Several fatigue testing methods are available, each with its advantages and limitations.

- Constant Amplitude Fatigue Testing: The most common method, where the stress amplitude remains constant throughout the test. It provides a basic understanding of fatigue behavior and is often used to generate S-N curves.

- Variable Amplitude Fatigue Testing: Simulates real-world loading conditions where stress amplitudes vary over time. This method is more complex but offers a more accurate prediction of fatigue life under realistic scenarios.

- Strain-Controlled Fatigue Testing: Focuses on strain rather than stress, particularly useful for ductile materials.

- Crack Growth Testing: Measures the rate at which fatigue cracks propagate under cyclic loading. This technique is vital for predicting the remaining life of a component with pre-existing cracks.

Fracture Mechanics: This branch of mechanics deals with the behavior of materials containing cracks. It allows for the prediction of crack growth rate and remaining life under fatigue loading.

- Stress Intensity Factor (K): A parameter used to characterize the stress field around a crack tip. It is crucial for understanding crack growth behavior.

- Paris Law: An empirical equation relating crack growth rate to stress intensity factor range.

1.2 Numerical Techniques

- Finite Element Analysis (FEA): A computer-based method used to simulate the stress and strain distribution in complex geometries. It helps predict fatigue life by identifying stress concentrations and crack initiation sites.

- Computational Fatigue Analysis: Combines FEA with fatigue models to predict the fatigue life of components under various loading conditions.

1.3 Other Techniques

- Acoustic Emission: Detects the high-frequency sound waves emitted during crack initiation and propagation.

- Ultrasonic Inspection: Uses sound waves to identify cracks and defects in materials.

- Metallographic Analysis: Examines the microstructure of the material using microscopy to identify fatigue damage mechanisms.

1.4 Conclusion

The combination of experimental, numerical, and other techniques provides a comprehensive approach to evaluating fatigue strength. By understanding the strengths and weaknesses of each method, engineers can select the most appropriate technique for their specific needs, ensuring the safety and reliability of components under cyclic loading.

Chapter 2: Models for Fatigue Strength Prediction

This chapter explores the various models used to predict the fatigue strength of materials and components. These models are essential for design engineers to ensure that components can withstand the intended cyclic loads over their operational lifespan.

2.1 S-N Curves and the Basquin Equation

- S-N Curve: A graphical representation of the relationship between stress amplitude and the number of cycles to failure. It is the most fundamental tool for fatigue life prediction.

- Basquin Equation: An empirical equation describing the linear portion of the S-N curve in a log-log scale. It is often used to predict fatigue life for high cycle fatigue.

2.2 Goodman Diagram

- Mean Stress Effect: The average stress level during cyclic loading can influence fatigue life. The Goodman diagram graphically represents this relationship.

- Goodman Equation: A mathematical expression that incorporates the mean stress effect in fatigue life prediction.

2.3 Fatigue Crack Growth Models

- Paris Law: An empirical equation that relates crack growth rate to stress intensity factor range. It is commonly used for predicting fatigue life in the presence of pre-existing cracks.

- Other Crack Growth Models: Various other models have been developed to improve the accuracy and scope of fatigue crack growth prediction, particularly in situations involving complex loading conditions.

2.4 Fatigue Damage Accumulation Models

- Miner's Rule: A linear damage accumulation model that predicts the fatigue life under variable amplitude loading. It assumes that each load cycle contributes proportionally to the total damage.

- Other Damage Accumulation Models: Several non-linear damage accumulation models have been proposed to account for the non-linear nature of fatigue damage under variable amplitude loading.

2.5 Fatigue Life Prediction Software

- Commercial Software: Several software packages are available for fatigue life prediction, incorporating various fatigue models and analysis techniques.

- Open-Source Software: Some open-source software options are available, providing a cost-effective alternative for fatigue analysis.

2.6 Conclusion

The models discussed in this chapter provide powerful tools for predicting fatigue life and ensuring component safety. By selecting the appropriate model for the specific application and incorporating realistic assumptions, engineers can achieve accurate and reliable fatigue life predictions.

Chapter 3: Software for Fatigue Analysis

This chapter explores the various software tools available for fatigue analysis. These software programs streamline the process of fatigue assessment and provide valuable insights into component behavior under cyclic loading.

3.1 Types of Fatigue Analysis Software

- General Purpose FEA Software: These software packages, such as ANSYS, Abaqus, and Nastran, provide comprehensive capabilities for structural analysis, including fatigue analysis modules.

- Specialized Fatigue Analysis Software: Software specifically designed for fatigue analysis, such as nCode DesignLife, Fe-Safe, and Fatigue Analyst, offer dedicated tools and features for predicting fatigue life.

- Open Source Fatigue Analysis Software: Several open source software programs, like FatigueX and pyFatigue, provide free alternatives for basic fatigue analysis.

3.2 Key Features of Fatigue Analysis Software

- Pre-Processing: Defining the geometry, material properties, and loading conditions for the analysis.

- Finite Element Analysis (FEA): Solving for the stress and strain distribution within the component.

- Fatigue Damage Calculation: Applying fatigue models and damage accumulation rules to estimate the fatigue life.

- Post-Processing and Visualization: Visualizing the results, including stress contours, crack propagation paths, and fatigue life contours.

- Reporting and Documentation: Generating reports and documentation for fatigue analysis findings.

3.3 Advantages of Using Fatigue Analysis Software

- Enhanced Accuracy: Software packages offer a more accurate and comprehensive approach to fatigue analysis, compared to manual calculations.

- Time and Cost Savings: Automation of fatigue analysis reduces the time and effort required for manual calculations.

- Improved Decision Making: Software provides valuable insights and visualizations that aid in design decisions.

- Enhanced Collaboration: Software packages facilitate collaboration and data sharing among engineers and designers.

3.4 Choosing the Right Fatigue Analysis Software

The choice of software depends on the complexity of the analysis, the desired level of accuracy, and available budget. Consider the following factors:

- Functionality and Features: Ensure that the software provides the necessary tools for your specific needs.

- Ease of Use and Learning Curve: Select software with a user-friendly interface and adequate learning resources.

- Compatibility and Integration: Choose software compatible with your existing CAD systems and other engineering tools.

- Cost and Licensing: Balance the cost of software with the potential benefits.

3.5 Conclusion

Fatigue analysis software plays a crucial role in ensuring the safety and reliability of components under cyclic loading. By leveraging the capabilities of these powerful tools, engineers can effectively analyze fatigue behavior, predict component life, and optimize designs to enhance durability and performance.

Chapter 4: Best Practices for Fatigue Strength Design

This chapter discusses crucial design principles and best practices for mitigating fatigue failure and enhancing the fatigue strength of components. Implementing these practices during design and manufacturing can significantly improve the reliability and lifespan of structures and machinery.

4.1 Design for Fatigue Resistance

- Avoid Stress Concentrations: Minimize geometric features that can concentrate stress, such as sharp corners, holes, and abrupt changes in cross-section. Employ fillets, rounds, and smooth transitions to redistribute stress.

- Optimize Geometry and Material Selection: Choose materials with inherent fatigue resistance and optimize component geometry to minimize stress amplitudes and improve load distribution.

- Consider Mean Stress Effects: Account for the average stress level during cyclic loading and employ design strategies to minimize its impact on fatigue life.

- Use Fatigue-Resistant Surface Treatments: Apply surface treatments like shot peening, surface rolling, and coatings to improve surface integrity and fatigue resistance.

4.2 Manufacturing and Assembly Considerations

- Control Manufacturing Tolerances: Maintain precise control over dimensions, tolerances, and surface finish during manufacturing to minimize stress concentrations and variations in fatigue strength.

- Minimize Residual Stresses: Implement processes like heat treatment and stress relieving to reduce residual stresses introduced during manufacturing and assembly.

- Avoid Defects and Imperfections: Ensure proper quality control during manufacturing to minimize defects, inclusions, and other imperfections that can initiate fatigue cracks.

- Proper Assembly and Handling: Handle components carefully during assembly to avoid damage that can compromise their fatigue strength.

4.3 Fatigue Testing and Verification

- Prototype Testing: Perform fatigue testing on prototypes to validate design assumptions and verify fatigue life predictions.

- In-Service Monitoring: Implement monitoring systems to track the fatigue loading experienced by components in actual service and identify potential fatigue problems early.

- Regular Inspections: Schedule regular inspections to identify fatigue cracks and other damage before they become critical.

4.4 Additional Best Practices

- Utilize Fatigue Design Guides and Standards: Consult established design guides and standards, such as ASME, ASTM, and ISO, for fatigue design recommendations and best practices.

- Seek Expert Advice: Consult with fatigue experts and specialists for complex fatigue design problems and for assistance in selecting appropriate materials and analysis techniques.

- Embrace Continuous Improvement: Continuously evaluate fatigue design practices and incorporate new technologies and insights to enhance fatigue resistance and extend component life.

4.5 Conclusion

By adhering to these best practices, engineers can create designs that effectively resist fatigue failure and ensure the long-term reliability of components under cyclic loading. By integrating fatigue considerations throughout the design, manufacturing, and operation phases, engineers can contribute to the safety, efficiency, and sustainability of various engineering systems.

Chapter 5: Case Studies in Fatigue Strength Applications

This chapter presents real-world case studies that illustrate the critical role of fatigue strength considerations in various engineering applications. These case studies highlight the importance of proper fatigue analysis, design practices, and material selection in ensuring component reliability and preventing catastrophic failures.

5.1 Case Study: Fatigue Failure of an Aircraft Wing

- Background: A fatigue crack developed in the wing of a commercial aircraft during flight, leading to an emergency landing.

- Cause of Failure: Stress concentration at a fastener hole and a lack of adequate fatigue analysis during the design phase.

- Lessons Learned: The importance of comprehensive fatigue analysis, including stress concentration effects, and the need for robust design practices to mitigate fatigue risks in aircraft components.

5.2 Case Study: Fatigue Failure of a Bridge Girder

- Background: A fatigue crack developed in a bridge girder, leading to concerns about structural integrity.

- Cause of Failure: Stress concentration at a weld joint and insufficient consideration of fatigue loading in the design.

- Lessons Learned: The importance of understanding the impact of welding on fatigue strength, using appropriate fatigue analysis techniques, and implementing proper inspection and maintenance procedures for bridge structures.

5.3 Case Study: Fatigue Life Extension of a Wind Turbine Blade

- Background: Wind turbine blades are subjected to significant cyclic loading from wind gusts, requiring robust fatigue design.

- Solution: Employing advanced composite materials, optimized blade geometry, and advanced fatigue analysis techniques to extend fatigue life and reduce maintenance costs.

- Lessons Learned: The advantages of using high-performance materials, incorporating design innovations, and leveraging advanced analysis tools for fatigue life optimization in wind turbine components.

5.4 Case Study: Fatigue Performance Enhancement of Medical Implants

- Background: Medical implants, such as hip replacements and dental implants, must withstand repeated loading from physiological stresses.

- Solution: Developing biocompatible materials with high fatigue strength, designing implants with optimized geometries, and performing rigorous fatigue testing to ensure long-term performance.

- Lessons Learned: The critical need for material selection, design optimization, and thorough testing to guarantee the reliability and longevity of medical implants.

5.5 Conclusion

These case studies demonstrate the real-world consequences of inadequate fatigue considerations and the importance of employing sound engineering practices to prevent fatigue failures. By learning from past failures and embracing best practices, engineers can design and manufacture components that are resilient against cyclic loading and contribute to the safe and reliable operation of various engineered systems.

- Corrosion Fatigue Corrosion Fatigue: A Silent T…

- Fatigue Fatigue: The Silent Killer of…

- Final Strength Final Strength: The Ultimate …

- Gel Strength Gel Strength: A Key Parameter…

- Gel Strength (drilling) Gel Strength: A Crucial Facto…

- Initial Gel Strength Understanding Initial Gel Str…

- Shear Strength Shear Strength: The Key to Ge…

- WBS (rock strength) WBS: The Bedrock of Wellbore …

- Rock Shear Strength Rock Shear Strength: A Crucia…

- Tensile Strength Tensile Strength: The Backbon…

- Yield Strength (metal) Understanding Yield Strength …

- Ultimate Strength The Ultimate Strength: A Mate…

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments