Drilling & Well Completion

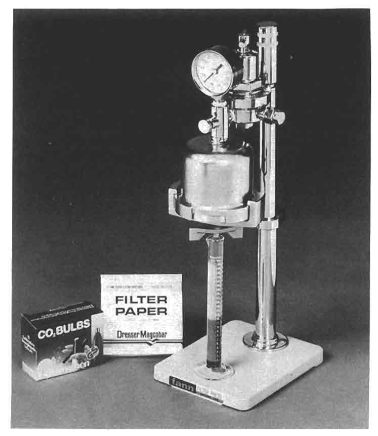

Fann Viscometer

The Fann Viscometer: A Crucial Tool for Oil & Gas Operations

The Fann Viscometer stands as a cornerstone instrument in the oil and gas industry, serving as a reliable tool for measuring the rheological properties of drilling fluids, cement slurries, and other oil-field fluids. Its ability to accurately determine viscosity under varying conditions makes it indispensable for optimizing drilling operations, cementing processes, and overall production efficiency.

What is a Fann Viscometer?

The Fann Viscometer is a rotational viscometer that measures the viscosity of non-Newtonian fluids, like drilling muds and cement slurries. These fluids exhibit a changing viscosity depending on the applied shear stress. Unlike Newtonian fluids, which have a constant viscosity, non-Newtonian fluids can become thinner or thicker with increasing shear rate.

How Does it Work?

The Fann Viscometer consists of a rotating bob (a cylindrical spindle) immersed in the fluid. The bob is connected to a rotating shaft, which is driven by a motor. The viscometer measures the torque required to rotate the bob at a specific speed, which is directly proportional to the fluid's viscosity. This torque is measured in units of "Fann Units" (FU).

Key Applications in Oil & Gas:

- Drilling Operations:

- Fluid Optimization: The Fann Viscometer helps determine the optimal mud viscosity for efficient drilling, ensuring adequate hole cleaning, bit stability, and formation stability.

- Preventing Hole Collapse: By adjusting the viscosity based on formation pressures, the Fann Viscometer aids in preventing wellbore instability and potential collapse.

- Cementing Operations:

- Slurry Characterization: The viscometer helps evaluate the rheological properties of cement slurries, ensuring proper flowability and placement in the wellbore.

- Preventing Channel Formation: It helps in designing cement slurries that minimize channel formation, ensuring a complete and effective cement job.

- Production Enhancement:

- Fluid Flow Analysis: The Fann Viscometer allows for the assessment of the flow behavior of produced fluids, aiding in optimizing production rates and minimizing flow restrictions.

- Downhole Equipment Design: By understanding the rheology of fluids, engineers can design downhole equipment that operates effectively under challenging conditions.

Advantages of the Fann Viscometer:

- Versatility: The Fann Viscometer can measure a wide range of viscosities, from low to high.

- Reliability: It provides consistently accurate results, contributing to reliable decision-making.

- Ease of Use: It is relatively easy to operate, requiring minimal training.

- Portability: The Fann Viscometer is available in both portable and lab-based versions, facilitating on-site measurements and quick analysis.

Summary:

The Fann Viscometer plays a pivotal role in ensuring safe and efficient oil and gas operations. Its ability to accurately measure the viscosity of non-Newtonian fluids, coupled with its versatility and user-friendliness, makes it an indispensable tool for optimizing drilling, cementing, and production processes. Its continued use throughout the industry highlights its enduring value in ensuring a successful and profitable oil and gas venture.

Test Your Knowledge

Fann Viscometer Quiz:

Instructions: Choose the best answer for each question.

1. What type of fluids does the Fann Viscometer primarily measure? a) Newtonian fluids b) Non-Newtonian fluids c) Both Newtonian and non-Newtonian fluids d) Gaseous fluids

Answer

b) Non-Newtonian fluids

2. What is the unit of measurement for torque in a Fann Viscometer? a) Pascal (Pa) b) Newton (N) c) Fann Units (FU) d) Centipoise (cP)

Answer

c) Fann Units (FU)

3. Which of the following is NOT a key application of the Fann Viscometer in oil and gas operations? a) Optimizing drilling mud viscosity b) Characterizing cement slurry properties c) Determining the pressure of a reservoir d) Assessing the flow behavior of produced fluids

Answer

c) Determining the pressure of a reservoir

4. What is a significant advantage of the Fann Viscometer? a) It can only measure low viscosities. b) It is expensive and requires specialized training to operate. c) It is versatile and can measure a wide range of viscosities. d) It is only available in stationary laboratory models.

Answer

c) It is versatile and can measure a wide range of viscosities.

5. How does the Fann Viscometer measure viscosity? a) By measuring the time it takes for a specific volume of fluid to flow through a narrow tube. b) By measuring the resistance a rotating bob experiences in the fluid. c) By measuring the density of the fluid. d) By measuring the temperature of the fluid.

Answer

b) By measuring the resistance a rotating bob experiences in the fluid.

Fann Viscometer Exercise:

Scenario: You are working on a drilling operation and need to adjust the drilling mud viscosity. The current mud has a viscosity of 40 FU. The recommended viscosity for optimal hole cleaning and bit stability in this formation is between 25 FU and 35 FU.

Task: Describe the steps you would take to adjust the mud viscosity to the desired range using the Fann Viscometer. Include the specific actions you would take based on the current viscosity reading.

Exercice Correction

Here's a possible solution:

Analyze the current viscosity: The current mud viscosity of 40 FU is higher than the recommended range (25-35 FU). This indicates that the mud is too thick and might hinder efficient hole cleaning and bit stability.

Determine the adjustment needed: We need to reduce the viscosity by approximately 5-15 FU.

Identify the mud properties to adjust: There are several ways to reduce mud viscosity. You could:

- Add water: Diluting the mud with water will generally decrease viscosity.

- Adjust the barite content: Barite is a weighting material that increases density and viscosity. Reducing the barite content can lower the viscosity.

- Add a viscosity reducer: Chemicals like lignosulfonate or other viscosity reducers can effectively lower the mud viscosity.

Start with a small adjustment: Begin with a small change to the mud, like adding a small amount of water or reducing the barite by a small percentage.

Measure the viscosity after each adjustment: Use the Fann Viscometer to measure the mud viscosity after each adjustment. Document the results and the adjustments made.

Continue adjusting until the desired viscosity is achieved: Continue adjusting the mud properties in small increments, measuring the viscosity after each change until the viscosity falls within the desired range of 25-35 FU.

Monitor the mud viscosity: Once the desired viscosity is achieved, continue to monitor the mud viscosity throughout the drilling operation. Factors like drilling rate, formation pressures, and the amount of cuttings in the mud can affect viscosity, so adjustments might be necessary.

Books

- Drilling Fluids: Fundamentals and Applications by George R. Gray (This comprehensive book covers drilling fluid properties, including viscosity, and the role of the Fann viscometer in drilling operations.)

- Cementing: Fundamentals and Applications by H.C. Hsieh and R.B. Graham (This book explores cement slurry rheology and the importance of Fann viscometer measurements in cementing operations.)

- Reservoir Engineering Handbook by Tarek Ahmed (While not focused solely on Fann Viscometer, this book provides a broad understanding of fluid flow in reservoirs, where viscosity plays a crucial role.)

Articles

- "Rheological Properties of Drilling Fluids" by J.C. Jaeger (This article discusses the different types of drilling fluids and their rheological behavior, emphasizing the importance of Fann viscometer measurements.)

- "The Role of Rheology in Cementing Operations" by P.D. O'Brien (This article focuses on the application of rheology, including Fann Viscometer measurements, in optimizing cement slurry properties for successful cementing.)

- "Viscosity and Its Influence on Drilling Fluid Performance" by S.P. Sharma (This article details the impact of viscosity on drilling fluid performance, highlighting the significance of Fann viscometer measurements in optimizing drilling operations.)

Online Resources

- Fann Instrument Company Website: This website provides detailed information about Fann viscometers, their applications, and technical specifications. (https://www.fanninstruments.com/)

- API Recommended Practice 13B-1: Drilling Fluids (API, 2019): This industry standard provides guidance on drilling fluid properties, including viscosity measurements, and the use of the Fann viscometer.

- SPE Journal: This online journal frequently publishes articles related to drilling fluids, cementing, and reservoir engineering, often including information on rheology and Fann viscometer applications.

Search Tips

- "Fann Viscometer drilling fluids": This search will provide articles and resources specific to the use of Fann viscometer in drilling fluids.

- "Fann Viscometer cement slurry": This search will lead you to resources related to Fann viscometer applications in cementing operations.

- "Fann viscometer measurement techniques": This search will guide you to resources explaining the specific methods used for measuring viscosity with a Fann viscometer.

- "Fann viscometer calibration": This search will provide information on ensuring the accuracy of your Fann viscometer measurements through proper calibration.

Techniques

The Fann Viscometer: A Deep Dive

This document expands upon the introductory material provided, breaking down the information into distinct chapters for clarity.

Chapter 1: Techniques

The Fann viscometer employs a rotational method to determine the viscosity of fluids. The core technique involves measuring the torque required to rotate a bob (spindle) immersed in the test fluid at a pre-determined rotational speed. This torque is directly proportional to the fluid's viscosity. Several key techniques are crucial for accurate measurements:

- Sample Preparation: Proper sample preparation is critical. This includes ensuring the sample is homogenous, free of air bubbles (degassing may be necessary), and at the correct temperature. The temperature of the sample significantly impacts viscosity, therefore precise temperature control is essential, often using a temperature-controlled bath.

- Calibration: Regular calibration of the Fann viscometer is vital for maintaining accuracy. This involves using standard fluids of known viscosities to verify the instrument's readings. Calibration procedures should adhere strictly to the manufacturer's instructions.

- Measurement Procedure: A standardized procedure should be followed to ensure consistent and reliable results. This includes carefully immersing the bob in the sample, allowing for equilibration, and recording the torque readings at various speeds (typically 300 and 600 rpm for drilling muds). Multiple readings at each speed are usually taken and averaged.

- Data Interpretation: The obtained torque readings are converted into Fann Units (FU) using the instrument's calibration. These FU values, alongside other rheological parameters, provide insights into the fluid's behavior under different shear rates. Understanding the rheological model (discussed in the next chapter) is crucial for correct interpretation.

- Advanced Techniques: Techniques like yield point determination (using the Marsh funnel or other methods in conjunction with the Fann viscometer) and gel strength measurement expand the capabilities of the Fann viscometer in characterizing drilling fluids.

Chapter 2: Models

The Fann viscometer primarily measures apparent viscosity, which changes depending on the shear rate applied. To understand and predict the fluid's behavior under different conditions, several rheological models can be used in conjunction with the Fann viscometer data:

- Power-Law Model: This is a common model used to describe the non-Newtonian behavior of drilling fluids. It relates shear stress to shear rate using parameters like consistency index (K) and flow behavior index (n). The Fann viscometer data provides the necessary measurements to determine these parameters.

- Bingham Plastic Model: This model represents fluids with a yield stress, meaning they behave as a solid until a certain stress is exceeded. The Fann viscometer data can be used to determine the yield stress and plastic viscosity.

- Herschel-Bulkley Model: This is a more complex model incorporating both yield stress and a shear-thinning behavior. This is a more accurate representation for some drilling fluids.

These models help predict the fluid’s behavior under various conditions, aiding in designing optimal drilling and cementing fluids. The choice of model depends on the specific fluid type and its rheological characteristics.

Chapter 3: Software

Modern Fann viscometers often come with integrated software or are compatible with software packages that automate data acquisition, analysis, and reporting. These software packages offer various features:

- Data Logging and Storage: Automated recording and storage of viscosity readings at various speeds and temperatures.

- Rheological Model Fitting: Software can fit the collected data to different rheological models (Power-law, Bingham Plastic, Herschel-Bulkley) to determine model parameters.

- Report Generation: Automatic generation of reports containing viscosity curves, model parameters, and other relevant information.

- Data Export: Exporting data to other software for further analysis and integration with other drilling or production management systems.

- Quality Control: Some software packages include features for quality control, flagging potential errors or outliers in the data.

The choice of software depends on the specific Fann viscometer model and the user's needs. Advanced software packages can significantly improve efficiency and data analysis capabilities.

Chapter 4: Best Practices

To ensure accurate and reliable results, several best practices should be followed when using a Fann viscometer:

- Regular Calibration: Regular calibration using certified standard fluids is crucial for maintaining accuracy. The frequency of calibration depends on the usage intensity and should be documented.

- Proper Cleaning and Maintenance: The viscometer should be cleaned thoroughly after each use to prevent cross-contamination and maintain its integrity. Regular maintenance, following the manufacturer’s guidelines, is essential for prolonging its lifespan.

- Temperature Control: Maintaining a constant temperature during measurements is critical as temperature significantly impacts viscosity. Use of a temperature-controlled bath is recommended.

- Standardized Procedures: Adherence to standardized operating procedures ensures consistency and reproducibility of results. These procedures should be documented and followed rigorously.

- Operator Training: Proper training of operators is essential to ensure accurate measurements and data interpretation. Training should include both theoretical and practical aspects of using the Fann viscometer.

- Data Management: Proper data management practices are crucial for traceability and future reference. Data should be stored securely and systematically.

Chapter 5: Case Studies

(This chapter requires specific examples of Fann viscometer applications. The following are illustrative examples and would need to be replaced with real-world case studies.)

- Case Study 1: Optimizing Drilling Mud Rheology: A drilling operation experienced difficulties with hole cleaning and wellbore instability. By using a Fann viscometer to carefully adjust the drilling mud rheology, the team optimized the mud's viscosity and yield point, resulting in improved hole cleaning and reduced risk of wellbore instability, leading to significant cost savings and improved drilling efficiency.

- Case Study 2: Ensuring Effective Cementing: In a challenging wellbore environment, a cementing operation utilized a Fann viscometer to analyze the rheological properties of the cement slurry. This analysis ensured that the slurry had the optimal rheology for proper placement and prevented channeling, leading to a successful cement job and avoiding costly remedial work.

- Case Study 3: Analyzing Produced Fluids: In an oil production scenario, the Fann viscometer helped analyze the flow behavior of produced fluids, identifying potential flow restrictions and contributing to the optimization of production rates and reduced downtime.

These case studies highlight the practical applications of the Fann viscometer and its contribution to improved efficiency and safety in oil and gas operations. Further examples could demonstrate its use in specific formations, with different drilling fluids, or in specific well completion scenarios.

- Fanning Equation (or friction factor) Understanding Friction Loss i…

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments