Drilling & Well Completion

PDC bit

PDC Bits: Revolutionizing Drilling Efficiency

In the demanding world of oil and gas exploration, drilling efficiency is paramount. This is where Polycrystalline Diamond Compact (PDC) bits shine. Unlike traditional roller cone bits, PDC bits employ a unique design that utilizes diamond-embedded cutting elements for superior performance.

What makes PDC bits stand out?

Superior Penetration Rates: PDC bits boast significantly higher penetration rates compared to roller cone bits, resulting in faster drilling times and reduced overall drilling costs. This is attributed to their sharp, durable diamond cutters that effectively cut through various rock formations.

Extended Bit Life: The robust diamond elements embedded in PDC bits provide exceptional wear resistance, allowing them to drill for longer durations before requiring replacement. This translates to fewer trips to the surface for bit changes, optimizing drilling operations.

Reduced Drilling Fluid Consumption: PDC bits generate less friction during drilling, leading to lower torque requirements. This reduced torque translates to less drilling fluid usage, minimizing environmental impact and operating costs.

Enhanced Hole Quality: PDC bits produce cleaner and straighter boreholes, minimizing the risk of wellbore instability and improving subsequent well completion operations.

Types of PDC Bits:

PDC bits come in various designs tailored for specific applications and geological conditions. Some common types include:

Matrix-Set PDC Bits: Featuring diamond cutters embedded within a matrix of metal, these bits are suitable for soft to medium-hard formations.

Integral PDC Bits: These bits integrate the diamond cutters directly into the bit body, providing exceptional durability for challenging formations.

Hybrid PDC Bits: Combining the advantages of matrix-set and integral designs, these bits offer versatility and enhanced performance for diverse drilling scenarios.

PDC Bits - A Game Changer for the Drilling Industry

PDC bits have revolutionized drilling practices, significantly impacting the oil and gas industry. Their superior performance, durability, and efficiency have not only reduced drilling time and costs but also contributed to improved wellbore stability and environmental sustainability. As the industry continues to seek innovative solutions for deeper and more challenging wells, PDC bits remain a key player in achieving drilling excellence.

Test Your Knowledge

PDC Bits Quiz

Instructions: Choose the best answer for each question.

1. What is the primary advantage of PDC bits over traditional roller cone bits?

a) Lower drilling costs b) Increased drilling speed c) Improved hole quality d) All of the above

Answer

d) All of the above

2. Which feature of PDC bits contributes to their superior penetration rates?

a) Diamond-embedded cutting elements b) Reduced friction during drilling c) Robust bit body design d) Enhanced hole quality

Answer

a) Diamond-embedded cutting elements

3. What type of PDC bit is best suited for drilling in soft to medium-hard formations?

a) Integral PDC bits b) Hybrid PDC bits c) Matrix-set PDC bits d) None of the above

Answer

c) Matrix-set PDC bits

4. How do PDC bits contribute to reduced drilling fluid consumption?

a) By generating less friction during drilling b) By requiring less torque for operation c) By providing extended bit life d) Both a) and b)

Answer

d) Both a) and b)

5. What is the main reason why PDC bits are considered a game changer for the drilling industry?

a) Their ability to drill through any type of rock formation b) Their low cost compared to traditional roller cone bits c) Their contribution to enhanced drilling efficiency and sustainability d) Their use in all types of drilling operations

Answer

c) Their contribution to enhanced drilling efficiency and sustainability

PDC Bits Exercise

Scenario: You are working on a drilling project in a region with hard, abrasive rock formations. You need to choose the most appropriate type of PDC bit for this specific application.

Task:

- Based on the information provided about different PDC bit types, which type would you recommend for this drilling project?

- Explain your reasoning for choosing this specific type of PDC bit.

Exercice Correction

The most suitable type of PDC bit for this scenario is the **Integral PDC bit**. Here's why:

- **Integral PDC bits** are designed for drilling through challenging formations due to their direct integration of diamond cutters into the bit body.

- This design provides exceptional durability and resistance to wear, making it ideal for handling hard, abrasive rock formations.

Books

- Drilling Engineering: By M.P. Chenevert (This book covers various aspects of drilling, including bit design and PDC bit technology.)

- Petroleum Engineering Handbook: Edited by Tarek Ahmed (This comprehensive handbook includes a section on drilling and discusses PDC bits in detail.)

Articles

- PDC Bit Technology: A Review (Available on ResearchGate and other scholarly platforms)

- The Evolution of PDC Bits by Schlumberger (Provides a historical perspective on PDC bit development and advancements)

- Understanding PDC Bit Performance by Halliburton (Explains factors influencing PDC bit performance and how to optimize their use)

- Comparative Study of Roller Cone and PDC Bits (Find relevant research articles published in journals like SPE Journal or Journal of Petroleum Science and Engineering)

Online Resources

- Schlumberger: https://www.slb.com/ (Schlumberger's website offers comprehensive information on their drilling products and services, including PDC bits.)

- Halliburton: https://www.halliburton.com/ (Halliburton's website provides insights into their PDC bit technology and application.)

- Baker Hughes: https://www.bakerhughes.com/ (Baker Hughes offers various drilling tools, including PDC bits, with detailed information available on their website.)

- IADC (International Association of Drilling Contractors): https://www.iadc.org/ (IADC website provides industry news and resources related to drilling, including information on PDC bits.)

Search Tips

- "PDC Bit" + "Review": This will find articles and resources providing an overview of PDC bit technology and their benefits.

- "PDC Bit" + "Types": This will lead you to information on different types of PDC bits and their specific applications.

- "PDC Bit" + "Performance": This will help you find research and technical papers exploring factors impacting PDC bit performance.

- "PDC Bit" + "Comparison" + "Roller Cone": This will direct you to resources comparing PDC bits with traditional roller cone bits, highlighting their advantages and disadvantages.

Techniques

Chapter 1: Techniques

PDC Bit Drilling Techniques

PDC bit drilling requires specific techniques and considerations to maximize their performance and ensure efficient and successful operations.

1. Bit Selection:

- Formation Evaluation: Analyzing rock formations with geological data and core samples is crucial to select the appropriate PDC bit design.

- Bit Size and Weight: Choosing the correct bit size and weight is essential to optimize penetration rates and minimize drilling fluid requirements.

- Number and Size of Cutters: The number and size of cutters determine the cutting capacity and wear characteristics, influencing bit life and drilling performance.

2. Drilling Parameters:

- Rotary Speed: Optimizing rotary speed is vital to achieve the desired penetration rate while minimizing bit wear and drilling fluid consumption.

- Weight on Bit (WOB): Adjusting WOB balances penetration rate and bit wear, influencing drilling efficiency and bit life.

- Drilling Fluid Properties: Selecting the appropriate drilling fluid type, density, and rheology ensures effective hole cleaning, bit lubrication, and formation stability.

3. Monitoring and Optimization:

- Downhole Data Analysis: Real-time monitoring of drilling parameters like rotary speed, WOB, torque, and penetration rate is critical to identify and adjust drilling conditions for optimal performance.

- Bit Performance Analysis: Regular analysis of bit wear patterns and drilling performance provides valuable insights for future bit selection and drilling strategy optimization.

4. Special Techniques:

- Directional Drilling: PDC bits are commonly used in directional drilling, requiring specialized techniques for steering and maintaining borehole trajectory.

- Underbalanced Drilling: PDC bits are suitable for underbalanced drilling, a technique that minimizes formation damage and enhances reservoir productivity.

5. Safety Considerations:

- Bit Run In: Proper run-in procedures ensure smooth engagement of the bit with the formation, minimizing sudden torque spikes and reducing bit damage.

- Bit Retrieval: Careful bit retrieval techniques protect the bit from damage and ensure efficient removal from the wellbore.

By carefully selecting PDC bits and implementing appropriate drilling techniques, operators can achieve exceptional drilling performance, reduce costs, and maximize well productivity.

Chapter 2: Models

Types of PDC Bits: A Detailed Look

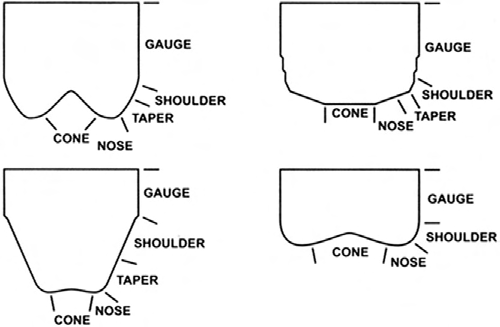

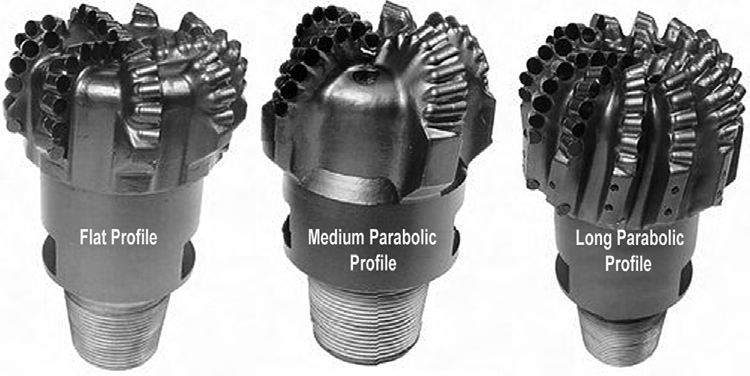

PDC bits come in a variety of designs, each optimized for specific applications and geological formations. Understanding these variations allows for informed bit selection, leading to increased drilling efficiency and cost savings.

1. Matrix-Set PDC Bits:

- Description: Diamond cutters are embedded within a metal matrix, providing a robust and versatile design.

- Applications: Suitable for drilling in soft to medium-hard formations, where the metal matrix provides support and stability.

- Advantages: Cost-effective, relatively high wear resistance, and versatile for different drilling conditions.

- Disadvantages: Lower penetration rates compared to integral PDC bits, can be susceptible to cutter loss in highly abrasive formations.

2. Integral PDC Bits:

- Description: Diamond cutters are directly integrated into the bit body, creating a single, highly durable structure.

- Applications: Ideal for drilling in hard and abrasive formations, where the integral design offers exceptional wear resistance.

- Advantages: Exceptional penetration rates, longer bit life, and high cutter retention.

- Disadvantages: Higher cost compared to matrix-set bits, may be less versatile in softer formations.

3. Hybrid PDC Bits:

- Description: Combining the advantages of matrix-set and integral designs, these bits offer a balance of durability and versatility.

- Applications: Suitable for drilling in a variety of formations, adapting to changing geological conditions.

- Advantages: Good penetration rates, decent wear resistance, and versatility for different drilling conditions.

- Disadvantages: May not be as efficient as integral bits in hard formations or as cost-effective as matrix-set bits in soft formations.

4. Specialized PDC Bits:

- Directional PDC Bits: Designed for steering the wellbore during directional drilling, incorporating features like jet nozzles and gauge pads for precise control.

- Underbalanced PDC Bits: Optimized for underbalanced drilling, with specialized designs for maximizing fluid flow and minimizing formation damage.

5. Advanced PDC Bit Designs:

- Multi-Blade PDC Bits: Utilizing multiple blades with diamond cutters, providing greater cutting area and enhanced penetration rates.

- High-Density PDC Bits: Featuring a higher concentration of diamond cutters, increasing wear resistance and improving performance in abrasive formations.

By understanding the unique characteristics and applications of different PDC bit models, operators can choose the best design for their specific drilling needs, maximizing efficiency and minimizing drilling costs.

Chapter 3: Software

PDC Bit Software: Tools for Optimization and Analysis

Software applications play a crucial role in optimizing PDC bit performance and analyzing drilling data for enhanced decision-making. These tools provide valuable insights, allowing operators to make informed decisions regarding bit selection, drilling parameters, and overall drilling operations.

1. Drilling Simulation Software:

- Function: Simulates PDC bit performance in various geological formations and drilling conditions.

- Benefits: Predicts bit life, penetration rates, and drilling fluid requirements, enabling operators to optimize drilling parameters for maximum efficiency.

- Examples: Drilling Simulator, WellPlanner, GeoMechanics.

2. Bit Selection Software:

- Function: Assists operators in selecting the appropriate PDC bit based on geological data, drilling parameters, and cost considerations.

- Benefits: Reduces the risk of selecting an unsuitable bit, minimizing downtime and optimizing drilling performance.

- Examples: Bit Selector, BitPlanner, PDCPro.

3. Drilling Data Analysis Software:

- Function: Analyzes drilling data, including penetration rates, weight on bit, torque, and drilling fluid properties, to identify trends and optimize drilling operations.

- Benefits: Provides real-time insights into bit performance, allowing operators to adjust drilling parameters for improved efficiency and reduced costs.

- Examples: Drilling Data Manager, WellWatch, DrillOp.

4. Bit Wear Analysis Software:

- Function: Analyzes bit wear patterns to predict bit life and identify potential problems, preventing premature bit failure.

- Benefits: Optimizes bit usage, reduces downtime, and minimizes drilling costs by identifying wear patterns and potential issues.

- Examples: Bit Wear Analyzer, PDC Life, BitWatch.

5. Drilling Optimization Software:

- Function: Combines data from various sources, including geological data, drilling parameters, and bit performance, to optimize drilling operations for maximum efficiency and cost reduction.

- Benefits: Provides comprehensive insights into drilling performance, enabling operators to make informed decisions and achieve optimal drilling results.

- Examples: Drilling Optimizer, WellMax, DrillPro.

By leveraging these software tools, operators can gain valuable insights into PDC bit performance, optimize drilling operations, and ultimately reduce drilling costs and enhance well productivity.

Chapter 4: Best Practices

Best Practices for Maximizing PDC Bit Performance

Achieving optimal PDC bit performance requires adhering to best practices that encompass bit selection, drilling techniques, and operational procedures. Implementing these best practices leads to enhanced drilling efficiency, minimized downtime, and reduced drilling costs.

1. Bit Selection:

- Thorough Formation Evaluation: Conduct detailed geological investigations to accurately characterize formations and select the appropriate PDC bit design.

- Consider Bit Size and Weight: Choose a bit size and weight that balances penetration rates and bit wear, ensuring optimal drilling performance.

- Evaluate Cutter Geometry: Select cutters with appropriate geometry and size for the specific rock formation, optimizing cutting efficiency and bit life.

2. Drilling Parameters:

- Optimize Rotary Speed: Adjust rotary speed based on formation hardness and bit design to maximize penetration rate while minimizing bit wear.

- Control Weight on Bit: Manage WOB to achieve a balance between penetration rate and bit wear, maximizing drilling efficiency and prolonging bit life.

- Optimize Drilling Fluid Properties: Select the appropriate drilling fluid type, density, and rheology for effective hole cleaning, bit lubrication, and formation stability.

3. Operational Procedures:

- Proper Bit Run-In: Ensure smooth bit engagement with the formation to minimize torque spikes and potential bit damage.

- Regular Monitoring and Adjustment: Continuously monitor drilling parameters like rotary speed, WOB, torque, and penetration rate to identify and address any issues impacting performance.

- Prevent Bit Damage: Handle bits carefully during transportation, installation, and retrieval to prevent potential damage and prolong bit life.

4. Data Analysis and Optimization:

- Analyze Bit Wear Patterns: Regularly examine bit wear to identify areas of excessive wear and adjust drilling parameters or bit selection for improved performance.

- Monitor Bit Life: Track bit life and compare it to expected performance to identify opportunities for improvement in drilling practices or bit selection.

- Utilize Software Tools: Leverage drilling simulation and data analysis software to optimize drilling parameters, predict bit life, and improve overall efficiency.

5. Collaboration and Training:

- Engage with Bit Manufacturers: Collaborate with PDC bit manufacturers to gather insights and recommendations for maximizing bit performance.

- Provide Operator Training: Ensure operators are adequately trained on PDC bit technology, drilling techniques, and safety procedures.

By adhering to these best practices, operators can maximize PDC bit performance, reduce drilling costs, and improve overall well productivity.

Chapter 5: Case Studies

Real-World Examples of PDC Bit Success Stories

Real-world case studies demonstrate the remarkable impact of PDC bits on drilling operations, showcasing their ability to increase drilling efficiency, reduce drilling costs, and improve well productivity. These examples illustrate the practical benefits of implementing PDC bit technology and adhering to best practices.

1. Enhanced Penetration Rates:

- Case Study: An operator drilling in a hard, abrasive formation achieved a 30% increase in penetration rates by switching from roller cone bits to PDC bits, significantly reducing drilling time and costs.

- Outcome: The increased penetration rate enabled the operator to complete the well faster, saving on drilling expenses and allowing for earlier production.

2. Extended Bit Life:

- Case Study: A company drilling in a highly abrasive formation experienced a 50% increase in bit life by utilizing PDC bits, significantly reducing bit replacement costs and minimizing downtime.

- Outcome: The extended bit life allowed for fewer trips to the surface for bit changes, optimizing drilling operations and reducing overall drilling costs.

3. Improved Hole Quality:

- Case Study: A drilling project in a challenging formation resulted in a significant reduction in wellbore instability and improved well completion operations by using PDC bits to create a cleaner and straighter borehole.

- Outcome: The improved hole quality minimized the risk of wellbore collapse, ensuring a successful well completion process and maximizing long-term productivity.

4. Reduced Drilling Fluid Consumption:

- Case Study: An operator utilizing PDC bits in a challenging drilling environment experienced a 20% reduction in drilling fluid consumption compared to using roller cone bits, minimizing environmental impact and operational costs.

- Outcome: The reduced drilling fluid consumption contributed to a more environmentally friendly drilling operation and reduced overall drilling costs.

5. Successful Directional Drilling:

- Case Study: A directional drilling project successfully navigated through complex geological formations with the aid of specialized PDC bits, achieving the target trajectory with precision and efficiency.

- Outcome: The successful directional drilling operation allowed for efficient access to the target reservoir, maximizing well productivity and minimizing environmental impact.

These case studies provide compelling evidence of the transformative impact of PDC bits on drilling operations, highlighting their ability to enhance efficiency, reduce costs, and improve overall well productivity.

Conclusion

PDC bits have revolutionized drilling operations, significantly enhancing drilling efficiency, reducing costs, and improving well productivity. By understanding the different types of PDC bits, adopting best practices, and utilizing software tools for optimization, operators can fully leverage the benefits of this innovative technology. These advancements continue to reshape the oil and gas industry, enabling exploration and production in increasingly challenging environments while minimizing environmental impact.

- Arbitrary Arbitrary: An Oil & Gas Enigm…

- Arbitration Arbitration in Oil & Gas: A C…

- babbitt Babbitting in Drilling & Well…

- backbite Backbite: The Silent Thief of…

- Bi-Center Bit Beyond the Basics: Unveiling …

- bit Cutting and Boring Elements U…

- Bit The Bit: A Crucial Component …

- Bit Breaker The Bit Breaker: A Crucial To…

- bit program Drilling a Hole: The Art of t…

- bit record The Bit Record: A Vital Tool …

- Bit Record Bit Record: A Chronicle of Dr…

- bit sub Understanding the Bit Sub in …

- Bit Sub Understanding Bit Subs: A Cru…

- Bit Weight (drilling) Bit Weight: The Driving Force…

- Bit Whirl (drilling) Bit Whirl: The Silent Killer …

- Babbitt Babbitt: The Unsung Hero of B…

- Backbite Backbite: A Silent Threat in …

- Bitumen Bitumen: The Viscous, Sticky …

- Bituminous Coal Bituminous Coal: The Workhors…

- Bituminous Coating Bituminous Coatings: Shieldin…

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments