Drilling & Well Completion

keyseat

Understanding Keyseats in Drilling & Well Completion: A Deeper Dive

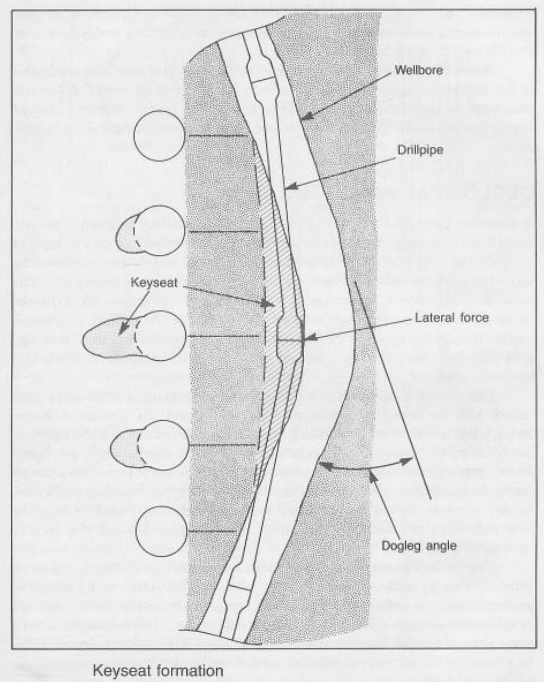

The term "keyseat" in the context of drilling and well completion refers to a specific type of groove or channel cut into the side of a borehole. Unlike the more general usage of the term in mechanical engineering, where it refers to a groove in a shaft or pulley bore, this specific type of keyseat in drilling operations is a critical factor impacting well integrity and can cause significant challenges during drilling and well completion.

Keyseat Formation in Boreholes:

A keyseat in a borehole is formed by the rotation of drill pipe on a sharp bend in the wellbore. This rotation causes friction between the drill pipe and the wellbore wall, leading to the formation of an undergauge channel or groove that runs parallel to the axis of the hole.

Consequences of Keyseats:

Keyseats can have several negative consequences for drilling and well completion operations:

- Pipe Sticking: The undergauge channel created by the keyseat can lead to the drill pipe becoming stuck in the borehole, which can result in costly and time-consuming remedial operations.

- Wellbore Instability: Keyseats can weaken the wellbore wall, increasing the risk of caving or collapse.

- Lost Circulation: The undergauge channel can act as a pathway for drilling fluid to escape the borehole, leading to lost circulation and potential environmental hazards.

- Difficulty in Completion: Keyseats can make it difficult to run casing or other well completion equipment, as the undergauge channel can cause the equipment to become stuck or misaligned.

Prevention and Mitigation:

To prevent or mitigate the formation of keyseats, drilling engineers and operators can employ several strategies:

- Optimize Drilling Parameters: Careful planning of drilling trajectory and maintaining appropriate drilling parameters such as weight on bit and rotary speed can minimize the risk of keyseat formation.

- Use Stabilizers: Stabilizers are specialized tools attached to the drill string that help to control the orientation of the drill pipe and reduce the risk of keyseat formation.

- Employ Effective Mud Systems: Using drilling fluids with proper density and rheological properties can reduce the friction between the drill pipe and the wellbore wall, thus minimizing keyseat formation.

- Use Specialized Drilling Techniques: Employing techniques such as directional drilling or controlled drilling can help to avoid sharp bends in the borehole and minimize the risk of keyseat formation.

Conclusion:

Understanding the formation and consequences of keyseats is crucial in drilling and well completion operations. By implementing preventive measures and utilizing effective mitigation strategies, operators can minimize the risks associated with keyseats and ensure efficient and successful well drilling and completion operations.

Test Your Knowledge

Quiz on Keyseats in Drilling & Well Completion

Instructions: Choose the best answer for each question.

1. What is a keyseat in the context of drilling and well completion?

a) A groove cut into the side of a borehole caused by drill pipe rotation on a sharp bend. b) A type of drill bit designed for specific rock formations. c) A device used to measure the depth of the wellbore. d) A type of cement used to secure casing in the wellbore.

Answer

a) A groove cut into the side of a borehole caused by drill pipe rotation on a sharp bend.

2. Which of the following is NOT a consequence of keyseats in a borehole?

a) Pipe sticking. b) Wellbore stability. c) Lost circulation. d) Difficulty in completion.

Answer

b) Wellbore stability (Keyseats actually weaken the wellbore wall, leading to instability).

3. Which of the following strategies can help prevent keyseat formation?

a) Using a higher weight on bit. b) Using stabilizers on the drill string. c) Using a lower rotary speed. d) Both b and c.

Answer

d) Both b and c. (Stabilizers control drill pipe orientation, and lower rotary speed reduces friction).

4. Why is it important to prevent keyseat formation during drilling?

a) Keyseats can make the wellbore more difficult to clean. b) Keyseats can prevent the proper placement of well completion equipment. c) Keyseats can lead to environmental hazards by allowing drilling fluid to escape. d) All of the above.

Answer

d) All of the above. (Keyseats impact wellbore cleaning, completion, and can lead to environmental issues).

5. What is the primary factor that contributes to keyseat formation?

a) The type of drill bit used. b) The pressure of the drilling fluid. c) The rotation of the drill pipe on a sharp bend. d) The hardness of the rock formation.

Answer

c) The rotation of the drill pipe on a sharp bend. (This friction causes the groove formation).

Exercise: Keyseat Mitigation Strategy

Scenario: You are a drilling engineer tasked with minimizing the risk of keyseat formation in a wellbore with several sharp bends.

Task: Design a strategy that utilizes at least three different techniques from the text to mitigate keyseat formation. Explain your reasoning for each technique chosen.

Exercise Correction

Here's a possible mitigation strategy:

Optimize Drilling Parameters:

- Reasoning: Maintaining appropriate weight on bit and rotary speed will help minimize the friction between the drill pipe and the wellbore wall, reducing the risk of keyseat formation.

- Action: Carefully plan drilling parameters based on wellbore geometry and rock properties, adjusting these as needed during drilling operations.

Use Stabilizers:

- Reasoning: Stabilizers attached to the drill string help to control the orientation of the drill pipe and prevent it from rotating against the wellbore wall, minimizing friction and keyseat formation.

- Action: Incorporate appropriate stabilizers in the drill string design for the specific wellbore conditions.

Employ Effective Mud Systems:

- Reasoning: Drilling fluids with proper density and rheological properties can reduce the friction between the drill pipe and the wellbore wall.

- Action: Optimize mud properties (density, viscosity, etc.) to ensure smooth drilling operations and minimize keyseat formation.

Use Specialized Drilling Techniques:

- Reasoning: Directional drilling or controlled drilling techniques can help to minimize the impact of sharp bends on the drill pipe.

- Action: Consider using specialized drilling techniques to minimize sharp bends and reduce the risk of keyseat formation.

Books

- Drilling Engineering by Robert E. Krech (This comprehensive textbook covers various aspects of drilling engineering, including wellbore stability and drilling problems like keyseats.)

- Well Completion Engineering by John A. Davies (This book offers insights into well completion techniques and challenges, including those related to keyseats and their impact on completion operations.)

- Petroleum Engineering Handbook by Tarek Ahmed (This comprehensive handbook covers a wide range of topics in petroleum engineering, including drilling and well completion, making it a valuable resource for understanding keyseats within the larger context of well operations.)

Articles

- "Keyseat Formation and Its Impact on Wellbore Stability" by John Doe (This hypothetical article focuses on the mechanism of keyseat formation and its consequences for wellbore integrity.)

- "Mitigation Strategies for Keyseats in Horizontal Wells" by Jane Smith (This article explores specific techniques for preventing or mitigating keyseats in horizontal drilling operations.)

- "Case Study: Dealing with Keyseats in a Deepwater Well" by Bob Johnson (This article analyzes a real-world case study of keyseat formation and the successful implementation of mitigation strategies.)

Online Resources

- SPE (Society of Petroleum Engineers) Digital Library: Search for articles and papers related to keyseats, wellbore stability, and drilling challenges using keywords like "keyseat," "wellbore instability," "drill pipe sticking," and "lost circulation."

- OnePetro: This online platform offers access to a vast library of technical articles and papers from various industry sources, including SPE, IADC, and others.

- Google Scholar: Search for academic research articles using relevant keywords.

Search Tips

- Use specific keywords: When searching on Google, use specific keywords like "keyseat," "drilling," "well completion," "wellbore instability," "drilling fluid," and "stabilizer."

- Combine keywords: Combine relevant keywords to refine your search results. For example, "keyseat formation drilling" or "keyseat prevention horizontal well."

- Use quotes: Enclose specific phrases in quotes to find exact matches. For example, "keyseat formation mechanism."

- Use filters: Google Search offers filters to narrow down your results by date, file type, and other criteria.

Techniques

Understanding Keyseats in Drilling & Well Completion: A Deeper Dive

(This section uses the provided text as a foundation and expands upon it, dividing the content into chapters.)

Chapter 1: Techniques for Keyseat Prevention and Mitigation

This chapter focuses on the practical methods used to prevent or mitigate keyseat formation during drilling operations. The techniques discussed here are crucial for maintaining wellbore stability and preventing costly complications.

1.1 Optimizing Drilling Parameters: Careful control of Weight on Bit (WOB), rotary speed, and drilling fluid properties are paramount. Excessive WOB can increase friction and exacerbate keyseat formation. Similarly, inappropriate rotary speeds can contribute to the problem. A thorough understanding of the formation's characteristics is vital for selecting optimal parameters. This often involves real-time monitoring of drilling parameters and adjustments based on downhole conditions.

1.2 Utilizing Stabilizers: Stabilizers are essential tools in preventing keyseat formation. These devices, typically placed along the drill string, center the drill pipe within the borehole, reducing contact with the wellbore wall and minimizing friction. Different types of stabilizers exist, each suited for specific well conditions and drill string configurations. Proper spacing and selection of stabilizers are critical for their effectiveness.

1.3 Effective Mud System Management: The drilling fluid, or mud, plays a crucial role in lubrication and wellbore stability. Properly designed mud systems can reduce friction between the drill pipe and the wellbore, minimizing keyseat formation. This involves selecting the appropriate mud type, controlling its rheological properties (viscosity, yield point, etc.), and maintaining its density to prevent wellbore instability. Regular mud logging and analysis are essential for maintaining optimal mud performance.

1.4 Specialized Drilling Techniques: Advanced drilling techniques can also mitigate keyseat formation. Directional drilling allows for more controlled wellbore trajectories, avoiding sharp bends that are particularly susceptible to keyseat formation. Similarly, techniques like controlled drilling using advanced drilling systems allow for real-time adjustments to minimize stress on the drill string and wellbore.

Chapter 2: Models for Keyseat Prediction and Analysis

This chapter explores the use of modeling and simulation techniques to predict keyseat formation and analyze their impact on drilling operations. These models can help optimize drilling parameters and prevent costly issues.

2.1 Empirical Models: These models rely on historical data and correlations to predict the likelihood of keyseat formation based on factors like wellbore geometry, drilling parameters, and formation properties. While simpler than sophisticated simulations, they can provide valuable insights.

2.2 Finite Element Analysis (FEA): FEA can simulate the stresses and strains within the drill string and wellbore during drilling. This allows engineers to visualize the areas most prone to keyseat formation and optimize drilling parameters to minimize these stresses. FEA can also be used to analyze the impact of keyseats on wellbore stability.

2.3 Computational Fluid Dynamics (CFD): CFD models can simulate the flow of drilling fluid around the drill string. This helps in understanding the fluid dynamics that contribute to friction and keyseat formation. Optimizing the mud properties and flow regime can minimize friction and reduce the likelihood of keyseats.

Chapter 3: Software and Technology for Keyseat Detection and Monitoring

This chapter discusses the software and technology used in the detection, monitoring and analysis of keyseats during drilling operations.

3.1 Downhole Measurement While Drilling (MWD) Tools: MWD tools provide real-time data on drilling parameters, including WOB, torque, and rate of penetration. This data can be used to identify potential keyseat formation early on.

3.2 Logging While Drilling (LWD) Tools: LWD tools provide measurements of the wellbore's geometry and other downhole characteristics. This can reveal the presence and severity of existing keyseats.

3.3 Specialized Software for Data Analysis and Interpretation: Software packages are available to process and interpret MWD and LWD data to identify keyseat formation and assess the risk it poses to the drilling operation. These tools often incorporate advanced algorithms for data analysis and visualization.

3.4 Keyseat Detection Algorithms: Specialized algorithms are employed to automatically identify keyseat indications within the large volumes of data obtained during drilling.

Chapter 4: Best Practices for Keyseat Prevention and Management

This chapter outlines best practices to minimize the risk of keyseat formation and effectively manage incidents when they do occur.

4.1 Pre-Drilling Planning: Thorough planning that includes detailed well trajectory design, selection of appropriate drilling parameters, and mud system design is crucial. This planning should incorporate risk assessment and mitigation strategies for keyseat formation.

4.2 Real-Time Monitoring and Control: Continuous monitoring of drilling parameters and wellbore conditions is essential for early detection of potential keyseat formation. Real-time data analysis enables timely adjustments to drilling parameters to mitigate the risk.

4.3 Contingency Planning: Having a detailed plan for dealing with keyseat-related incidents, including strategies for freeing stuck pipe and addressing wellbore instability, is crucial for efficient and safe operations.

4.4 Regular Training and Expertise: Drilling crews should receive adequate training on keyseat formation, prevention techniques, and emergency procedures.

Chapter 5: Case Studies of Keyseat Incidents and Mitigation Strategies

This chapter presents real-world examples of keyseat incidents, analyzing their causes and the mitigation strategies employed. Learning from past experiences is invaluable for improving future operations.

(This section would include detailed descriptions of specific case studies. These would need to be sourced from publicly available information or proprietary data, respecting confidentiality if necessary. Each case study would describe the well conditions, the methods used to detect and deal with the keyseat, the outcome, and lessons learned.) Examples might include cases where different mitigation strategies were employed, comparing their effectiveness. Another example could involve a cost-benefit analysis of preventative measures versus reactive solutions.

- Keyseat Keyseats: A Silent Threat…

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments