Drilling & Well Completion

kelly saver sub

The Kelly Saver Sub: Protecting Your Investment in the Drilling Process

In the high-stakes world of oil and gas exploration, every component plays a crucial role. One often overlooked but essential element is the Kelly Saver Sub, a seemingly simple piece of equipment that plays a vital role in safeguarding the longevity and efficiency of your drilling operations.

Understanding the Kelly Saver Sub

The Kelly Saver Sub is a heavy, relatively short length of pipe that acts as an intermediary between the Kelly and the drill pipe. It's essentially a protective buffer, strategically positioned to minimize wear and tear on the Kelly, a critical component in the drilling process.

Why It Matters

The Kelly is a massive, rotating, and often highly-stressed piece of machinery that connects the drilling rig's top drive to the drill string. Due to the constant movement and friction during drilling operations, the Kelly is prone to wear and tear, particularly on its threads.

This is where the Kelly Saver Sub steps in. Its strong, durable construction and precise threading design ensure that the drill pipe threads engage with the sub's threads, effectively reducing the stress and wear on the Kelly. By protecting the Kelly from excessive wear, the Kelly Saver Sub helps to:

- Extend the lifespan of the Kelly: Reducing wear on the Kelly means extending its useful life, saving you time and money on costly replacements.

- Minimize downtime: A damaged Kelly can result in significant downtime for drilling operations, impacting project schedules and overall efficiency.

- Enhance drilling performance: A well-maintained Kelly translates to smoother, more reliable drilling, minimizing interruptions and maximizing productivity.

- Reduce maintenance costs: By protecting the Kelly, you can reduce the frequency and cost of maintenance, saving valuable resources.

Choosing the Right Kelly Saver Sub

The selection of a Kelly Saver Sub is not a one-size-fits-all decision. Several factors come into play, including:

- Drilling depth: The deeper the drilling operation, the more stress the Kelly experiences, requiring a more robust Kelly Saver Sub.

- Drilling environment: Harsh conditions, such as high temperatures or abrasive formations, may require specialized Kelly Saver Subs designed to withstand extreme environments.

- Drilling fluid: The type of drilling fluid used can also influence the selection of a Kelly Saver Sub, as certain materials may be more resistant to corrosion or wear caused by specific fluids.

Conclusion

The Kelly Saver Sub might seem like a small, insignificant piece of equipment, but its importance in safeguarding the Kelly cannot be overstated. It's a simple yet effective solution that contributes significantly to the overall efficiency, safety, and cost-effectiveness of drilling operations. By investing in a high-quality Kelly Saver Sub, you're investing in the longevity of your drilling equipment and the success of your project.

Test Your Knowledge

Kelly Saver Sub Quiz

Instructions: Choose the best answer for each question.

1. What is the primary function of a Kelly Saver Sub?

a) To connect the Kelly to the drill string. b) To prevent wear and tear on the Kelly. c) To increase the drilling speed. d) To regulate the flow of drilling fluid.

Answer

b) To prevent wear and tear on the Kelly.

2. Which of the following is NOT a benefit of using a Kelly Saver Sub?

a) Extended Kelly lifespan. b) Reduced drilling downtime. c) Increased drilling depth. d) Enhanced drilling performance.

Answer

c) Increased drilling depth.

3. What factor should be considered when choosing a Kelly Saver Sub?

a) The type of drilling rig being used. b) The weight of the drill pipe. c) The drilling environment. d) The brand of the drilling fluid.

Answer

c) The drilling environment.

4. How does a Kelly Saver Sub protect the Kelly from wear and tear?

a) By acting as a shock absorber. b) By absorbing the drilling fluid. c) By redirecting the drilling force. d) By engaging the drill pipe threads, minimizing Kelly thread engagement.

Answer

d) By engaging the drill pipe threads, minimizing Kelly thread engagement.

5. Why is it important to use a high-quality Kelly Saver Sub?

a) It guarantees a longer drilling operation. b) It reduces the overall cost of drilling. c) It ensures optimal performance and reduces potential issues. d) It enhances the aesthetic appeal of the drilling rig.

Answer

c) It ensures optimal performance and reduces potential issues.

Kelly Saver Sub Exercise

Scenario: You are responsible for selecting a Kelly Saver Sub for a new drilling project in a harsh, high-temperature environment. The drilling depth is expected to be around 10,000 feet.

Task:

- Identify the key factors you need to consider when selecting a Kelly Saver Sub for this specific project.

- Explain how these factors will influence your decision in choosing the appropriate Kelly Saver Sub.

- Research and suggest at least two specific Kelly Saver Sub models that could be suitable for this project, providing their key features and benefits.

Exercice Correction

**Key factors to consider:** * **Drilling depth:** 10,000 feet requires a robust Kelly Saver Sub capable of handling high stress and wear. * **Drilling environment:** High-temperature conditions demand a Kelly Saver Sub with high temperature resistance and potentially special materials or coatings. * **Drilling fluid:** The type of drilling fluid used will influence the Kelly Saver Sub's material selection to prevent corrosion or degradation. **How these factors influence the decision:** * **Deep drilling:** A heavier-duty Kelly Saver Sub with thicker walls and robust threading will be necessary. * **High temperature:** Look for Kelly Saver Subs made from heat-resistant materials like high-alloy steel or those with specialized heat-resistant coatings. * **Drilling fluid compatibility:** Ensure the Kelly Saver Sub is compatible with the specific drilling fluid being used to prevent corrosion and premature failure. **Suggested Kelly Saver Sub models:** * **Model 1:** (Real-world example of a high-temperature, heavy-duty Kelly Saver Sub) - Describe its features, materials, and benefits related to high temperature and depth. * **Model 2:** (Another suitable model) - Describe its key features, materials, and benefits, contrasting it with the first model. Remember to research actual Kelly Saver Sub models from reputable manufacturers and provide specific product names and specifications in your suggestions.

Books

- Drilling Engineering: Principles and Applications by John C. Collins

- Petroleum Engineering Handbook by Society of Petroleum Engineers

- Drilling and Well Completion: A Practical Guide by R. B. Stewart

- Oil Well Drilling Technology by W. C. Lyons

Articles

- "Kelly Saver Sub: Protecting Your Investment in the Drilling Process" (This article)

- "The Role of Kelly Saver Sub in Reducing Drilling Costs and Improving Efficiency" (Search online)

- "Selecting the Right Kelly Saver Sub for Your Drilling Operation" (Search online)

- "Kelly Saver Sub Design and Performance: A Case Study" (Search academic databases like JSTOR, ScienceDirect, or Google Scholar)

Online Resources

- Baker Hughes: https://www.bakerhughes.com/

- Halliburton: https://www.halliburton.com/

- Schlumberger: https://www.slb.com/

- National Oilwell Varco (NOV): https://www.nov.com/

Search Tips

- "Kelly Saver Sub" + "Drilling Equipment"

- "Kelly Saver Sub" + "Oil and Gas"

- "Kelly Saver Sub" + "Technical Specifications"

- "Kelly Saver Sub" + "Manufacturer"

- "Kelly Saver Sub" + "Case Studies"

- "Kelly Saver Sub" + "Industry Standards"

- "Kelly Saver Sub" + "Best Practices"

- "Kelly Saver Sub" + "Maintenance"

- "Kelly Saver Sub" + "Troubleshooting"

- "Kelly Saver Sub" + "Safety"

Techniques

The Kelly Saver Sub: A Comprehensive Guide

Chapter 1: Techniques for Using and Maintaining Kelly Saver Subs

This chapter focuses on the practical aspects of employing and maintaining Kelly Saver Subs to maximize their effectiveness and lifespan.

Proper Installation: The correct installation of a Kelly Saver Sub is paramount. This includes ensuring proper alignment with the Kelly and drill pipe, using appropriate torque specifications, and verifying the secure connection to prevent leaks or slippage during operation. Incorrect installation can lead to premature wear and tear on both the Kelly Saver Sub and the Kelly itself. Detailed diagrams and step-by-step instructions for various types of Kelly Saver Subs would be beneficial here, along with visual aids.

Regular Inspection: Routine visual inspection for signs of wear, damage, or corrosion is crucial. This should include checking for scratches, dents, thread damage, and any indication of material fatigue. A schedule for regular inspections should be established, dependent on factors such as drilling depth, environmental conditions, and drilling fluid type. Clear guidelines on what constitutes acceptable wear and when replacement is necessary are important.

Lubrication and Cleaning: Proper lubrication of threads is vital to reduce friction and wear during make-up and break-out operations. Regular cleaning to remove drilling mud and debris is also necessary to prevent corrosion and maintain optimal performance. Recommendations on appropriate lubricants and cleaning methods should be included, taking into account compatibility with different drilling fluids.

Troubleshooting: This section will address common issues encountered with Kelly Saver Subs, such as stuck threads, leaks, or unexpected wear. Practical solutions and preventative measures for each issue should be detailed. For example, techniques for freeing stuck threads or identifying the root cause of leaks are crucial for minimizing downtime.

Chapter 2: Models and Types of Kelly Saver Subs

This chapter will explore the various designs and materials used in Kelly Saver Subs.

Material Selection: Different materials are used in the construction of Kelly Saver Subs, each with its own advantages and disadvantages. Common materials include high-strength steel alloys, specialized steels resistant to corrosion and high temperatures, and other advanced materials that can withstand extreme drilling conditions. This section should discuss the properties of different materials and their suitability for various drilling environments. Considerations such as corrosion resistance, wear resistance, and strength should be addressed.

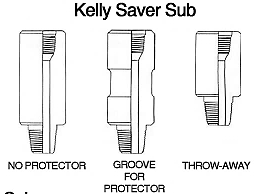

Design Variations: Kelly Saver Subs come in various designs to accommodate different Kelly sizes and drilling parameters. This section should explore these variations, including differences in thread design, length, and overall geometry. The impact of these design features on performance and lifespan should be discussed.

Specialized Subs: This section would cover specialized Kelly Saver Subs designed for specific applications, such as those used in high-temperature, high-pressure (HTHP) wells or those with enhanced corrosion resistance for specific drilling fluids.

Chapter 3: Software and Data Analysis for Kelly Saver Sub Management

This chapter will explore how software can improve the management of Kelly Saver Subs.

Data Acquisition and Logging: Integrating sensors into Kelly Saver Subs allows for real-time monitoring of key parameters, such as torque, axial load, and temperature. This data can be used to optimize drilling operations and predict potential failures. This section would detail suitable sensor technologies and data acquisition methods.

Predictive Maintenance: Using data analytics and machine learning techniques, software can analyze historical data and predict potential failures in Kelly Saver Subs, allowing for proactive maintenance and preventing costly downtime. This section would discuss the application of these techniques in predicting Kelly Saver Sub failures and optimizing maintenance schedules.

Inventory Management Software: Effective inventory management is crucial for ensuring the availability of appropriate Kelly Saver Subs when needed. This section would discuss software solutions for tracking inventory, managing stock levels, and forecasting future needs.

Chapter 4: Best Practices for Kelly Saver Sub Utilization

This chapter focuses on the optimal practices for maximizing the benefits of Kelly Saver Subs.

Selection Criteria: This section will refine the selection process based on drilling depth, environment, and fluid type, providing detailed guidelines and decision-making frameworks.

Preventive Maintenance Schedules: A detailed schedule for regular inspections, lubrication, and cleaning will be provided, considering factors like drilling hours, environmental conditions, and material degradation rates.

Training and Personnel: Proper training for rig crews on the correct installation, operation, and maintenance of Kelly Saver Subs is crucial to prevent accidents and maximize their lifespan. This section emphasizes the importance of skilled personnel and comprehensive training programs.

Cost-Benefit Analysis: This section will provide a framework for evaluating the cost-effectiveness of using Kelly Saver Subs, considering the costs of acquisition, maintenance, and potential savings from reduced downtime and extended Kelly lifespan.

Chapter 5: Case Studies of Kelly Saver Sub Application

This chapter will present real-world examples of Kelly Saver Sub usage and its impact on drilling operations.

Case Study 1: This case study could showcase a drilling project where the use of a high-quality Kelly Saver Sub significantly extended the lifespan of the Kelly, reducing downtime and saving considerable costs.

Case Study 2: This case study might focus on a challenging drilling environment (e.g., high-temperature, high-pressure well) where a specialized Kelly Saver Sub proved essential for successful drilling operations.

Case Study 3: This case study could highlight a situation where a failure to use or properly maintain a Kelly Saver Sub resulted in significant downtime and increased costs, serving as a cautionary tale.

Each case study should provide detailed information on the drilling conditions, the type of Kelly Saver Sub used, and the results achieved. Quantifiable data, such as cost savings and downtime reduction, should be included wherever possible. This chapter will demonstrate the practical value and importance of Kelly Saver Subs in various drilling scenarios.

- Activity Subtask Activity Subtask within a Pro…

- AUV (subsea) AUV (Subsea): The Unmanned Ex…

- Basket or Basket Sub Catching the Fall: Basket and…

- bent sub Bent Sub: The Unsung Hero of …

- Bent Sub Bent Subs: Navigating the Pat…

- bit sub Understanding the Bit Sub in …

- Bit Sub Understanding Bit Subs: A Cru…

- Boot Sub Boot Sub: A Vital Tool in the…

- CID (subsea) CID: The Unsung Hero of Subse…

- Circulation Sub Circulation Sub: A Lifeline f…

- Completion Bore Protector (subsea) Shielding the Heart of Subsea…

- crossover sub Bridging the Gap: Crossover S…

- Crown Plugs (subsea) Crown Plugs: Guardians of the…

- crown saver Crown Saver: A Safety Lifelin…

- BML (subsea) BML: The Underwater Lifeline …

- CATs (subsea) CATs: Connecting the Dots in …

- CIT (subsea) CIT (Subsea): The Chemical In…

- Crossover Sub Bridging the Gap: Understandi…

- Crown Saver Keeping the Block in Check: U…

- CVAR (subsea) CVAR: Enabling Efficient and …

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments