Ingénierie des réservoirs

Salt Dome

Le secret salé du pétrole et du gaz : explorer les dômes de sel

Les dômes de sel, de grandes formations souterraines de sel gemme, sont bien plus que de simples ingrédients culinaires. Dans le monde de l'exploration pétrolière et gazière, ces structures géologiques jouent un rôle crucial, à la fois comme de potentiels trésors et de potentiels défis.

Un flux lent et constant :

Imaginez un liquide épais et visqueux qui s'infiltre lentement à travers un solide. C'est l'essence d'un dôme de sel. Ces formations sont créées sur des millions d'années lorsque des couches de sel, enfouies profondément dans la terre, sont soumises à une pression et à une chaleur intenses. Cela provoque la mobilité du sel, comme un glacier se déplaçant lentement, et il "coule" progressivement à travers les formations rocheuses environnantes.

Le piège du réservoir :

Les dômes de sel sont très recherchés par les compagnies pétrolières et gazières car ils créent souvent des conditions idéales pour l'accumulation d'hydrocarbures.

- Structure : Le mouvement ascendant du sel crée une structure en forme de dôme, repoussant les couches de roche existantes.

- Barriers imperméables : Le sel est imperméable, ce qui signifie qu'il ne permet pas aux fluides de le traverser. Cela agit comme une barrière, piégeant le pétrole et le gaz dans les couches de roche poreuses sous le dôme.

- Formation du réservoir : La pression ascendante du sel peut également déformer et plier les formations rocheuses environnantes, créant des pièges supplémentaires pour les hydrocarbures.

Un défi salé :

Cependant, les dômes de sel présentent également des défis importants pour les opérations pétrolières et gazières:

- Effondrement du tubage : Le mouvement du sel peut exercer une pression immense sur les tubages de puits, entraînant une défaillance structurelle et des fuites potentielles.

- Instabilité du puits : La présence de sel peut rendre difficile le forage et le maintien de puits stables.

- Corrosion : Le sel est très corrosif, présentant des risques pour l'équipement et réduisant potentiellement la durée de vie des puits.

Naviguer dans le sel :

Malgré les défis, les récompenses potentielles de l'exploration des dômes de sel en font une cible précieuse pour les compagnies pétrolières et gazières. Des technologies de pointe comme l'imagerie sismique 3D permettent une analyse détaillée de ces formations, permettant de meilleures stratégies de forage et de minimiser les risques.

L'avenir du sel :

Alors que l'exploration pétrolière et gazière continue de s'enfoncer dans des environnements plus profonds et plus complexes, la compréhension des dômes de sel est cruciale. Des recherches et des innovations supplémentaires dans les techniques de forage et les matériaux sont nécessaires pour naviguer efficacement dans ces géants salés et déverrouiller leurs ressources cachées tout en assurant des opérations sûres et durables.

Test Your Knowledge

Quiz: The Salty Secret to Oil & Gas

Instructions: Choose the best answer for each question.

1. What is the primary reason salt domes are important to oil and gas exploration?

a) They provide a source of salt for drilling fluids. b) They create ideal conditions for hydrocarbon accumulation. c) They are rich in natural gas deposits. d) They are easily accessible for drilling.

Answer

b) They create ideal conditions for hydrocarbon accumulation.

2. How are salt domes formed?

a) Volcanic eruptions pushing up salt layers. b) Chemical reactions between seawater and rock. c) Intense pressure and heat causing salt to flow upwards. d) Erosion of surrounding rock layers exposing salt deposits.

Answer

c) Intense pressure and heat causing salt to flow upwards.

3. What makes salt domes act as a trap for oil and gas?

a) Their high porosity allows for easy oil and gas flow. b) They are impermeable, preventing oil and gas from escaping. c) They contain natural gas hydrates that release gas upon drilling. d) They are filled with cavities that act as natural reservoirs.

Answer

b) They are impermeable, preventing oil and gas from escaping.

4. What is a major challenge associated with drilling in salt domes?

a) High temperatures can melt drilling equipment. b) Salt can corrode equipment and cause wellbore instability. c) Salt domes are often located in remote and inaccessible areas. d) Salt formations are too dense to penetrate with current drilling technology.

Answer

b) Salt can corrode equipment and cause wellbore instability.

5. What technology is crucial for understanding and navigating salt domes during oil and gas exploration?

a) Satellite imagery for mapping salt dome locations. b) 3D seismic imaging for detailed analysis of salt formations. c) Deep sea drilling equipment for accessing salt domes under the ocean. d) Artificial intelligence for predicting salt dome movements.

Answer

b) 3D seismic imaging for detailed analysis of salt formations.

Exercise: The Salty Challenge

Imagine you are an oil and gas engineer working on a project to extract hydrocarbons from a salt dome. You need to present a plan to your team that addresses the potential challenges posed by the salt formation. Include:

- Potential risks associated with salt domes: Corrosion, wellbore instability, casing collapse, etc.

- Strategies to mitigate these risks: Special drilling techniques, corrosion-resistant materials, advanced monitoring systems, etc.

- Importance of thorough geological analysis and advanced technologies: 3D seismic imaging, simulations, etc.

Instructions: Create a short presentation or written report outlining your plan to your team, highlighting the importance of understanding and managing the challenges presented by salt domes.

Exercice Correction

This exercise is designed to assess your understanding of the challenges associated with salt domes and your ability to propose solutions. A strong response would demonstrate:

- Identification of key risks: Corrosion, wellbore instability, casing collapse, salt creep, etc.

- Effective mitigation strategies: Special drilling fluids, corrosion-resistant materials, cementing techniques, real-time monitoring, advanced well design.

- Emphasize the role of geological analysis and technologies: 3D seismic imaging, salt dome simulations, wellbore stability analysis.

- Clear and concise presentation: Structured plan, logical flow of information, and easy-to-understand language.

Remember, the key is to present a well-rounded plan that showcases your understanding of the challenges and how you would approach them as an oil and gas engineer.

Books

- Petroleum Geology by Selley, R. C. (2005): This comprehensive textbook covers salt dome formation, their role as hydrocarbon traps, and challenges associated with their exploration.

- Salt Tectonics by Jackson, M. P. A. & Talbot, C. J. (2011): This book provides detailed information on salt tectonics, including the formation, evolution, and implications of salt domes for hydrocarbon exploration.

- The Geology of Petroleum by Levorsen, A. I. (1967): A classic text that explores various geological features relevant to oil and gas exploration, including salt domes.

Articles

- "Salt Domes: A Geological Overview" by Rowan, M. G. & Laubach, S. E. (AAPG Bulletin, 2001): This article provides a detailed overview of salt dome formation and their importance in hydrocarbon accumulation.

- "Salt Tectonics: A Review" by Talbot, C. J. & Jackson, M. P. A. (Journal of Structural Geology, 1992): This article reviews various aspects of salt tectonics, including their impact on hydrocarbon exploration.

- "Drilling Challenges in Salt Domes" by Williams, B. & Maughan, A. (SPE Journal, 2005): This article discusses challenges related to drilling in salt domes, including casing collapse and wellbore instability.

Online Resources

- AAPG (American Association of Petroleum Geologists): Their website has numerous publications and resources related to salt tectonics and hydrocarbon exploration.

- SPE (Society of Petroleum Engineers): This organization provides articles, case studies, and technical papers focused on oil and gas production, including challenges associated with drilling in salt domes.

- USGS (United States Geological Survey): Their website offers geological information and maps related to salt domes in various regions.

Search Tips

- Use specific keywords: "salt dome formation," "salt dome hydrocarbon traps," "salt dome drilling challenges," "salt tectonics oil exploration."

- Combine keywords with location: "salt domes Gulf of Mexico," "salt domes North Sea."

- Use quotation marks for specific phrases: "salt dome exploration techniques."

- Filter by publication type: "salt dome drilling articles," "salt dome geology books."

Techniques

Chapter 1: Techniques for Exploring Salt Domes

The exploration and exploitation of hydrocarbons trapped within or adjacent to salt domes require specialized techniques due to the unique geological challenges presented by these formations. These challenges include the salt's plasticity, its potential for diapirism (upward movement), and its corrosive nature. The following techniques are crucial for successful exploration and production:

1. Seismic Imaging: High-resolution 3D and 4D seismic surveys are essential for detailed mapping of salt dome structures. These techniques provide images of the subsurface, revealing the shape, size, and internal structure of the salt dome, as well as the surrounding sedimentary layers where hydrocarbons might be trapped. Advanced processing techniques, such as pre-stack depth migration (PSDM), are often necessary to accurately image the complex geometry of salt bodies.

2. Well Logging: Once a well is drilled, various logging tools are used to characterize the formations encountered. These tools measure properties such as porosity, permeability, and fluid saturation, helping to identify potential hydrocarbon reservoirs. Special logging tools are needed to cope with the harsh conditions presented by salt formations, including high temperatures and pressures.

3. Drilling Techniques: Drilling through salt domes presents unique challenges due to the salt's plasticity and tendency to flow. Specialized drilling fluids and techniques are required to maintain wellbore stability and prevent borehole collapse. Directional drilling and horizontal drilling are often employed to reach reservoirs located beneath or around the salt dome. This may involve the use of advanced drilling bits and real-time monitoring of wellbore conditions.

4. Formation Evaluation: A comprehensive formation evaluation program is crucial to determine the producibility of any discovered hydrocarbon reservoirs. This involves integrating data from seismic surveys, well logs, and core analysis to build a detailed geological model of the reservoir. This model is then used to optimize production strategies.

5. Reservoir Simulation: Numerical reservoir simulation is used to predict the behavior of the reservoir under various production scenarios. This helps to optimize production rates and maximize hydrocarbon recovery. The simulations must account for the complex geometry and physical properties of the salt dome and the surrounding formations.

Chapter 2: Geological Models of Salt Domes

Understanding the geological processes that form and influence salt domes is paramount for successful exploration and production. Several models attempt to explain the formation and evolution of these structures:

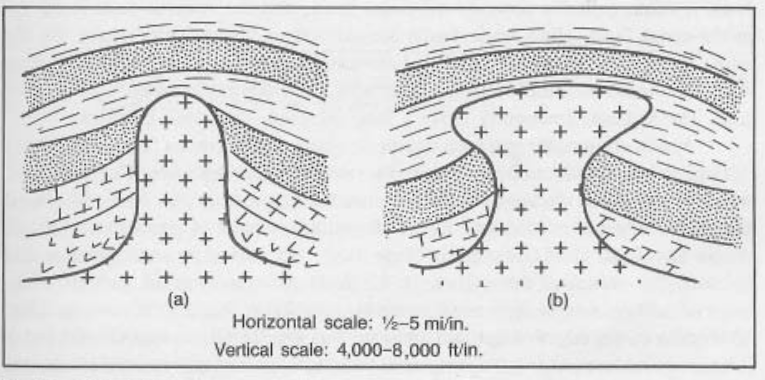

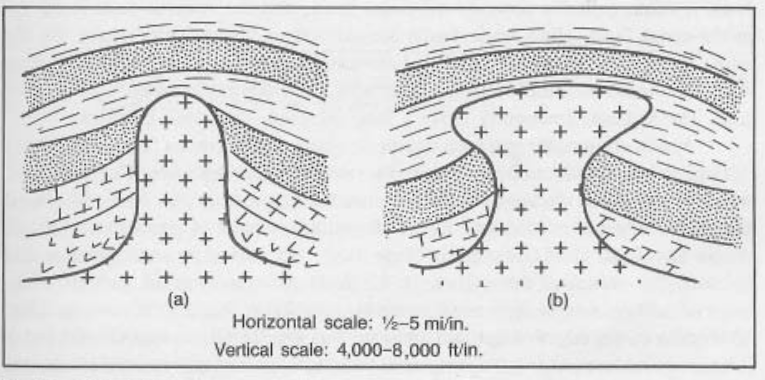

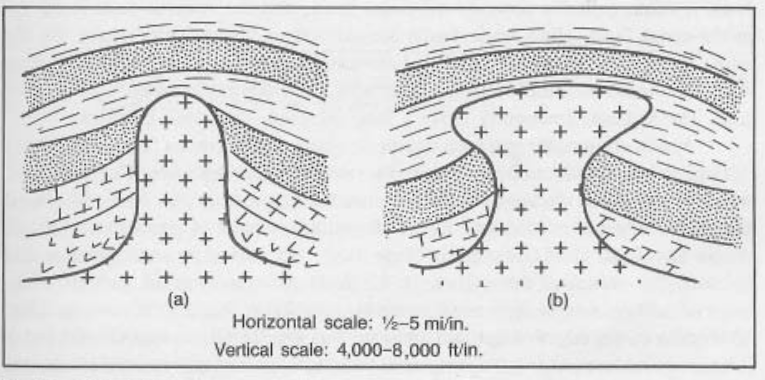

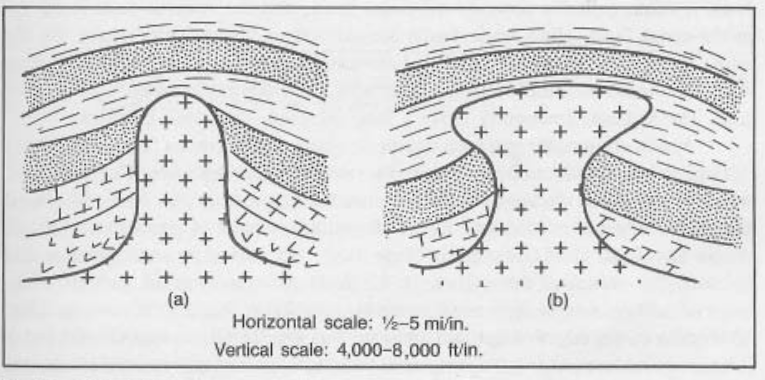

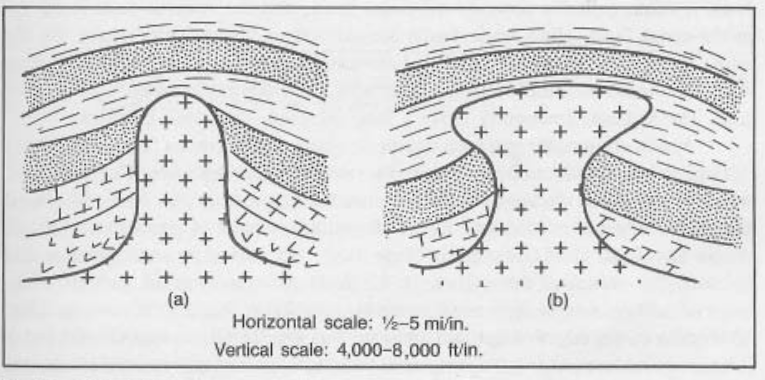

1. Diapirism: The most widely accepted model for salt dome formation is diapirism. This involves the upward movement of less dense salt through denser overlying sediments due to density contrasts and tectonic forces. The salt rises as a diapir, deforming the surrounding strata and creating traps for hydrocarbons. Different models exist to explain the dynamics of this process, considering factors like buoyancy forces, sediment loading, and tectonic stress.

2. Halokinesis: This term encompasses the various kinematic processes involved in salt movement, including flow, folding, and faulting. Understanding these processes is crucial for predicting the shape and distribution of hydrocarbons within and around the salt dome.

3. Structural Models: Geologists use structural geological models to reconstruct the history of deformation and the current three-dimensional configuration of the salt dome and surrounding strata. These models often incorporate data from seismic surveys, well logs, and geological mapping. They help predict the location of potential hydrocarbon traps and assess the risk of drilling hazards.

4. Hydrocarbon Trap Models: Specific models are used to understand how hydrocarbons are trapped within and around salt domes. These traps can include: * Stratigraphic traps: Hydrocarbons are trapped by changes in rock permeability and porosity. * Structural traps: Hydrocarbons are trapped by folds and faults created by the upward movement of the salt. * Combination traps: Hydrocarbons are trapped by a combination of stratigraphic and structural factors.

5. Dynamic Models: These integrate the effects of pressure, temperature, and fluid flow to better understand the evolution of the salt dome and its impact on reservoir properties over time. They can help predict how the reservoir will respond to production.

Chapter 3: Software for Salt Dome Exploration and Production

Sophisticated software packages are essential for managing the vast amounts of data involved in salt dome exploration and production. These tools facilitate interpretation, modeling, and simulation. Key software categories include:

1. Seismic Interpretation Software: Packages like Petrel, Kingdom, and SeisSpace are used to process and interpret seismic data, creating 3D images of the subsurface. These tools allow for the identification of salt bodies, faults, and potential hydrocarbon reservoirs. Advanced algorithms are used to handle the complex wave propagation effects associated with salt.

2. Well Log Analysis Software: Software such as Techlog and Interactive Petrophysics are used to analyze well log data, determining porosity, permeability, and fluid saturation. These tools help characterize reservoirs and estimate hydrocarbon reserves.

3. Reservoir Simulation Software: Software like Eclipse, CMG, and STARS are used to model reservoir behavior under various production scenarios. These tools consider the complex geometry and properties of salt domes to predict production rates and optimize recovery strategies.

4. Geological Modeling Software: Software such as Gocad and Leapfrog Geo are used to build 3D geological models of salt domes and their surrounding formations. These models integrate data from seismic surveys, well logs, and geological mapping to create a comprehensive understanding of the subsurface.

5. Data Management Software: Specialized software is used to manage the large datasets involved in salt dome exploration and production. These systems facilitate data sharing, collaboration, and efficient workflow management. Geospatial database systems and cloud-based platforms are increasingly used to manage this data effectively.

Chapter 4: Best Practices for Salt Dome Exploration and Production

Safe and efficient exploration and production in salt dome environments requires adherence to best practices:

1. Comprehensive Pre-Drilling Planning: Thorough geological and geophysical studies are crucial before drilling begins. This involves detailed seismic imaging, well log analysis, and geological modeling to understand the complexities of the salt dome and its surrounding formations. This minimizes drilling risks and improves the chances of successful hydrocarbon discovery.

2. Advanced Drilling Techniques: Specialized drilling techniques and fluids are required to maintain wellbore stability while drilling through plastic salt formations. Real-time monitoring of drilling parameters is essential to prevent wellbore collapse and other hazards.

3. Wellbore Stability Management: The use of appropriate drilling muds and casing programs is critical to prevent wellbore instability. Regular monitoring of wellbore pressure and temperature is needed to prevent casing failure.

4. Corrosion Management: Salt is highly corrosive; therefore, corrosion-resistant materials and inhibitors are required for well completion and production equipment. Regular inspection and maintenance are essential to extend the life of equipment.

5. Environmental Monitoring and Protection: Rigorous environmental monitoring programs are needed to protect the environment from potential hazards associated with salt dome exploration and production. This includes monitoring of air and water quality, and management of drilling waste.

6. Risk Assessment and Management: A comprehensive risk assessment is essential to identify and mitigate potential hazards throughout the project lifecycle. This involves considering geological, technical, and environmental risks.

7. Data Integration and Collaboration: Effective data management and integration are crucial for making informed decisions. This requires close collaboration between geologists, geophysicists, engineers, and other specialists.

Chapter 5: Case Studies of Salt Dome Exploration and Production

Several case studies illustrate the complexities and successes of salt dome exploration and production. Specific examples should be included here, detailing:

Successful discoveries: Discuss fields where significant hydrocarbon reserves were found within or adjacent to salt domes, highlighting the techniques used and the challenges overcome. Include details on reservoir characteristics, production rates, and recovery factors. Examples from the Gulf of Mexico, North Sea, or other regions with significant salt dome provinces would be relevant.

Drilling challenges and solutions: Describe specific instances where drilling difficulties were encountered (e.g., wellbore instability, casing collapse, salt creep), and how these challenges were addressed using innovative techniques and technologies.

Environmental considerations: Showcase examples of effective environmental management strategies implemented during salt dome exploration and production, including waste management and mitigation of potential environmental impacts.

Technological advancements: Highlight the role of technological advancements (e.g., advanced seismic imaging, improved drilling techniques, enhanced oil recovery methods) in improving the efficiency and safety of salt dome operations.

Each case study should provide a concise description of the geological setting, exploration and production strategies employed, and the key results achieved, drawing lessons learned and best practices for future endeavors. The inclusion of specific geographic locations and company names (where appropriate and publicly available) will add value and credibility to the case studies.

- Basalt Basalte : La pierre angulaire…

- Dome Dômes : Les Trésors Cachés de…

- Salt Bed Storage Stockage en gisement de sel :…

- Salt Cavern Les cavernes de sel : Un stoc…

- Subsalt Sous-sel : Dévoiler des tréso…

- Domestic production Production nationale : la lig…

- Rock Salt Sel gemme : un outil essentie…

- Saltation Saltation : Les particules qu…

- Salt Bridging Material Matériau de pontage salin : U…

- Sized Salt Sel Fin : Un Acteur Clé dans …

- Salt (brine) Le Sel (Saumure) dans le Pétr…

- Salt Water (production) Eau Salée (Production) : Une …

- Demande de justification des dépenses Naviguer dans la de… Planification et ordonnancement du projet

- Coût budgété du travail planifié Comprendre le Coût … Estimation et contrôle des coûts

- Les limites de batterie Comprendre les limi… Termes techniques généraux

- Outil DV Outil DV : Un éléme… Forage et complétion de puits

- SOMMAIRE TOC : Comprendre le… Termes techniques généraux

Comments