Traitement du pétrole et du gaz

Production Separator

Séparateurs de Production : La Première Étape Essentielle dans le Traitement du Pétrole et du Gaz

Dans le monde de la production pétrolière et gazière, un séparateur de production joue un rôle vital. Il constitue la première étape cruciale du traitement, où les fluides bruts multiphasés extraits du puits sont séparés en leurs composants individuels : le pétrole, le gaz et l'eau. Ce processus de séparation est essentiel pour un traitement en aval efficace et la maximisation des ressources précieuses.

Comprendre le Processus de Séparation :

Imaginez un mélange complexe de pétrole, de gaz et d'eau s'écoulant du puits. Ce mélange, appelé « fluide produit », est hautement pressurisé et contient des quantités importantes de gaz dissous. Le séparateur de production, un grand réservoir sous pression, utilise une combinaison de principes physiques pour réaliser cette séparation :

- Réduction de la Pression : Lorsque le fluide produit entre dans le séparateur, sa pression est réduite. Cette réduction permet aux gaz dissous de sortir de la solution et de former des bulles de gaz.

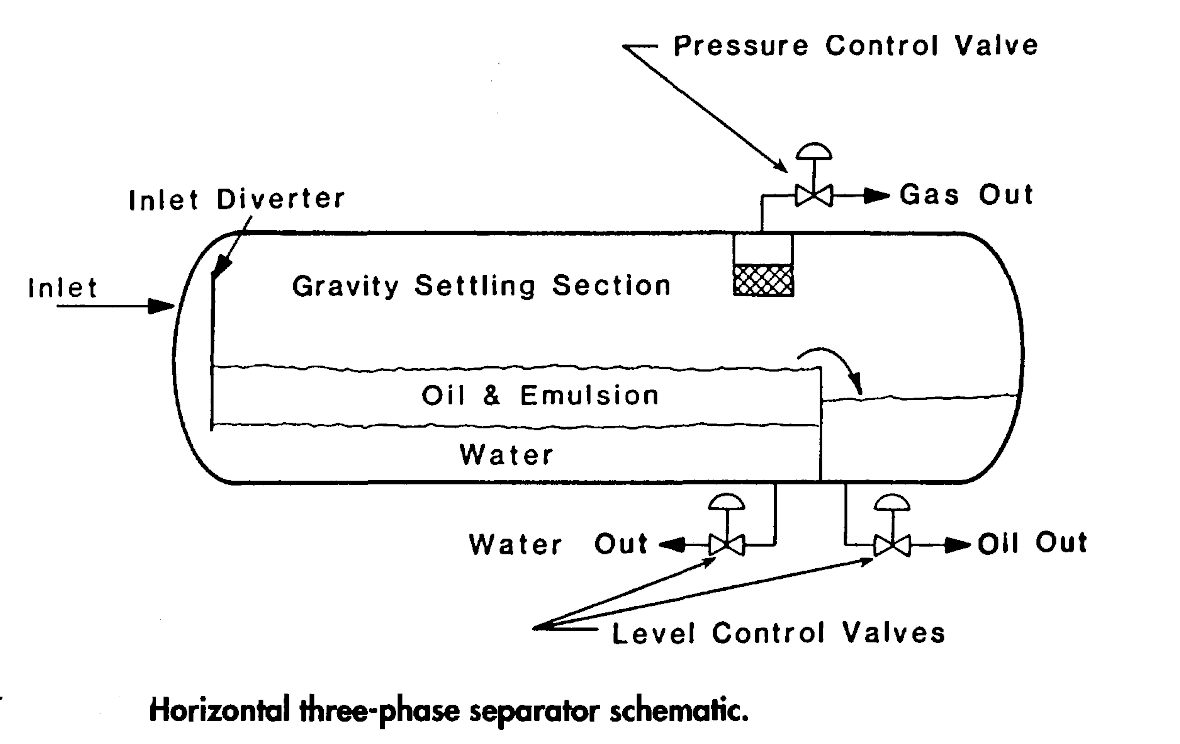

- Séparation par Gravité : Le séparateur est conçu avec différentes sections, permettant aux phases liquides plus lourdes (pétrole et eau) de se déposer au fond, tandis que la phase gazeuse plus légère monte vers le haut.

- Interfaces de Phase : Des composants internes, tels que des chicanes et des éliminateurs de brouillard, contribuent à améliorer davantage la séparation en créant des interfaces de phase définies, empêchant l'entraînement de gouttelettes liquides dans le flux de gaz.

Types de Séparateurs de Production :

Les séparateurs de production peuvent être classés de manière générale en fonction de la stratégie de séparation de phase utilisée :

- Séparateurs Biphasés : Ces séparateurs traitent un mélange de pétrole et de gaz, où l'eau est minime.

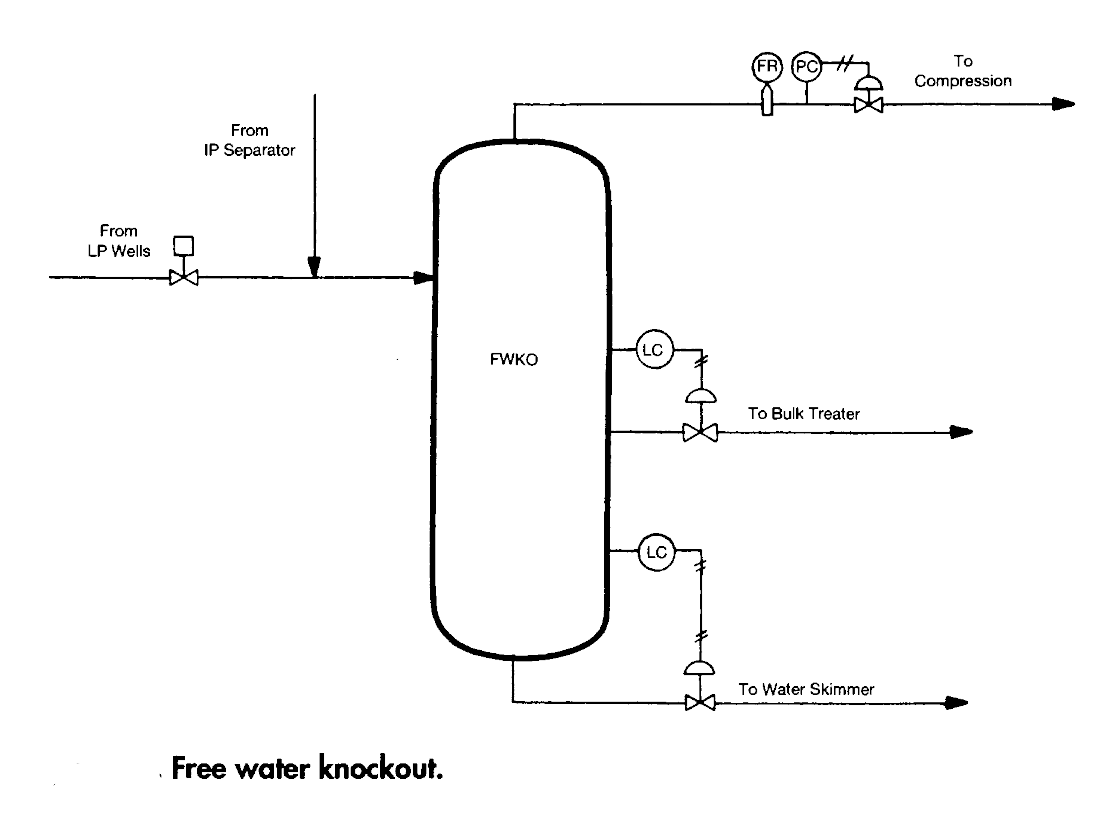

- Séparateurs Triphasés : Ces séparateurs sont conçus pour gérer les trois phases (pétrole, gaz et eau) et sont couramment utilisés dans les scénarios de production à forte teneur en eau.

Au-delà de la Séparation :

Les séparateurs de production ne se contentent pas de séparer les fluides. Ils jouent également un rôle crucial dans :

- L'élimination du Sable et des Solides : Les composants internes peuvent aider à capturer le sable et les particules solides, protégeant les équipements en aval des dommages.

- Le Contrôle des Débits : La conception du séparateur et ses composants internes contribuent à réguler les débits des fluides séparés, garantissant un traitement optimal.

- La Surveillance et le Contrôle : Des systèmes d'instrumentation et de contrôle intégrés au séparateur assurent une surveillance continue de la pression, de la température et des niveaux de fluide, permettant une intervention et une optimisation rapides.

Conclusion :

Les séparateurs de production sont des composants essentiels dans les installations de production pétrolière et gazière. Ils garantissent que les ressources précieuses sont extraites, traitées et transportées efficacement en aval de la chaîne de production. Comprendre leur fonctionnement, leurs types et leurs capacités est essentiel pour optimiser l'efficacité de la production et maximiser l'utilisation des ressources.

Test Your Knowledge

Production Separators Quiz:

Instructions: Choose the best answer for each question.

1. What is the primary function of a production separator?

a) To increase the pressure of produced fluids.

Answer

Incorrect. Production separators reduce pressure.

b) To mix oil, gas, and water.

Answer

Incorrect. Production separators separate these phases.

c) To separate oil, gas, and water from the produced fluid.

Answer

Correct. This is the primary function of a production separator.

d) To transport produced fluids to storage tanks.

Answer

Incorrect. This is a separate process after separation.

2. What physical principle allows dissolved gases to come out of solution in a production separator?

a) Gravity

Answer

Incorrect. While gravity plays a role, pressure reduction is the primary driver.

b) Pressure reduction

Answer

Correct. Lowering the pressure allows dissolved gases to form bubbles.

c) Phase interface

Answer

Incorrect. Phase interfaces help with separation, not the initial gas release.

d) Temperature increase

Answer

Incorrect. Temperature changes are not the primary driver in this process.

3. What type of production separator is suitable for handling mixtures with high water content?

a) Two-phase separator

Answer

Incorrect. Two-phase separators are designed for oil and gas mixtures.

b) Three-phase separator

Answer

Correct. Three-phase separators handle oil, gas, and water.

c) Single-phase separator

Answer

Incorrect. Single-phase separators are not used in production scenarios.

d) Multi-phase separator

Answer

Incorrect. While "multi-phase" is often used, three-phase is the specific type.

4. What is one way production separators help control flow rates?

a) By using pumps to regulate flow.

Answer

Incorrect. Pumps are not used directly within the separator.

b) By creating pressure differentials.

Answer

Correct. Design and internal components can create pressure differences to manage flow.

c) By heating the fluids.

Answer

Incorrect. Heating is not typically used to control flow rates.

d) By adding chemicals to the fluids.

Answer

Incorrect. Chemicals are not used to directly control flow rates.

5. Which of the following is NOT a benefit of using production separators?

a) Maximizing resource utilization.

Answer

Incorrect. Efficient separation leads to better resource use.

b) Reducing the risk of equipment damage.

Answer

Incorrect. Separators remove solids and help protect equipment.

c) Increasing the cost of production.

Answer

Correct. Separators are an expense, but their benefits outweigh the cost.

d) Ensuring efficient downstream processing.

Answer

Incorrect. Separation is essential for efficient downstream processes.

Production Separators Exercise:

Task: Imagine you are an engineer working on a new oil and gas production facility. The well produces a high volume of produced fluid with a significant amount of dissolved gas and water.

Design a production separator system for this facility, considering the following:

- Type of separator: Should you use a two-phase or three-phase separator? Justify your choice.

- Key components: Identify at least three essential components for the chosen separator, explaining their function.

- Monitoring and control: Explain how you would monitor and control the separator system to ensure optimal performance.

Exercise Correction:

Exercice Correction

Here's a possible solution for the exercise: **Type of Separator:** * A **three-phase separator** would be the appropriate choice. This is because the well produces a significant amount of water along with oil and gas. A three-phase separator is designed to efficiently separate these three phases. **Key Components:** * **Inlet Separator:** This component receives the produced fluid and reduces its pressure, allowing dissolved gases to come out of solution. * **Gas-Liquid Separator:** This section promotes the separation of the lighter gas phase from the heavier liquid phases (oil and water). * **Water-Oil Separator:** This section is designed to separate the water phase from the oil phase, allowing for their separate processing. **Monitoring and Control:** * **Pressure Gauges:** Monitoring pressure at various points within the separator is crucial. This helps to ensure that the pressure reduction is adequate for efficient separation. * **Level Sensors:** Sensors monitor the levels of oil, gas, and water in their respective sections. This allows for timely intervention if levels become too high or low. * **Temperature Sensors:** Monitoring temperature provides insights into potential issues like overheating or excessive cooling, which can impact separation efficiency. * **Flow Meters:** Flow meters track the volume of oil, gas, and water produced. This information is critical for production optimization. **Additional Considerations:** * **Mist Eliminators:** These devices are used to prevent liquid droplets from being carried away with the gas stream, enhancing the purity of the separated gas. * **Sand Filters:** To protect downstream equipment, a sand filter can be installed in the separator to remove any solid particles like sand. * **Instrumentation and Control System:** A control system would be integrated with the separator to provide continuous monitoring, data logging, and automated control of flow rates, pressures, and other key variables.

Books

- "Petroleum Production Systems" by E.J. Chowdhury: Covers a comprehensive overview of oil and gas production, including sections dedicated to separators and their design.

- "Production Operations" by John M. Campbell: Provides detailed insights into production operations, with chapters specifically focusing on separators and their role in fluid separation.

- "The Oil and Gas Production Handbook" by Bill G. Cobb: Offers a practical guide to oil and gas production, including information on various types of separators and their applications.

- "Handbook of Petroleum Engineering" by D.R. Mills: A comprehensive reference covering all aspects of petroleum engineering, including sections on separator design and operation.

Articles

- "Production Separators: Design, Operation, and Maintenance" by SPE: This SPE article provides a detailed explanation of separator types, design considerations, and operational best practices.

- "Understanding Production Separators and Their Importance in Oil and Gas Production" by Oil and Gas Journal: A practical overview of the role and importance of production separators in the oil and gas industry.

- "Optimizing Production Separator Performance for Enhanced Efficiency" by Hydrocarbon Engineering: This article discusses various techniques and strategies for improving separator efficiency and maximizing resource utilization.

- "The Evolution of Production Separators: From Conventional to Advanced Designs" by World Oil: Explores the technological advancements in separator design and their impact on the industry.

Online Resources

- "Production Separator Design and Operation" - Schlumberger: Provides a comprehensive guide to production separators, including their types, operating principles, and troubleshooting.

- "Production Separators" - Halliburton: Offers a detailed explanation of separator design and functionality, along with insights into their application in different production scenarios.

- "Separators - Oil and Gas" - Flowserve: Provides information on various types of separators, their features, and their role in oil and gas processing.

- "Production Separators - Oil and Gas Processing" - Chevron: Offers a technical overview of production separators and their importance in downstream processing.

Search Tips

- Use specific search terms like "production separators types," "separator design principles," "three-phase separator operation," or "production separator troubleshooting."

- Combine search terms with relevant industry keywords like "oil and gas," "petroleum engineering," or "upstream production."

- Utilize advanced search operators like "site:" to limit your search to specific websites, like those of equipment manufacturers or industry publications.

- Include specific keywords related to your specific area of interest, such as "horizontal separators," "high-pressure separators," or "gas-liquid separators."

Techniques

Chapter 1: Techniques

1.1 Introduction

This chapter delves into the fundamental techniques employed in production separators to achieve effective separation of oil, gas, and water from the multi-phase fluid stream extracted from a well.

1.2 Pressure Reduction

The initial step in separation involves reducing the pressure of the produced fluid. This pressure reduction triggers the release of dissolved gases, forming gas bubbles that can be easily separated. This process can be achieved through various methods:

- Choke Valve: A simple and commonly used method, a choke valve restricts flow, reducing pressure and promoting gas release.

- Pressure Reduction Valve: This device provides controlled pressure reduction, allowing for precise control of the separation process.

- Flash Tank: A vessel where pressure is reduced rapidly, leading to significant gas release and facilitating separation.

1.3 Gravity Separation

Once pressure reduction allows for the formation of gas bubbles, gravity plays a crucial role. The separator's design ensures that heavier liquid phases (oil and water) settle at the bottom, while the lighter gas phase rises to the top. This separation is aided by:

- Vertical Design: The vertical orientation of the separator allows for efficient gravity settling.

- Internal Baffles: These components act as obstacles to the fluid flow, promoting settling and reducing turbulence.

- Horizontal Settling Zones: Dedicated zones within the separator are designed to allow for longer settling times, enhancing separation efficiency.

1.4 Phase Interfaces

Internal components such as baffles, mist eliminators, and coalescers are designed to create defined phase interfaces between the separated fluids. These interfaces prevent the entrainment of liquid droplets in the gas stream, ensuring a purer gas phase.

- Mist Eliminators: These elements capture and remove fine liquid droplets from the gas stream, achieving greater purity.

- Coalescers: These components promote the merging of smaller droplets into larger ones, aiding in gravity settling and improving separation efficiency.

1.5 Other Techniques

- Centrifugal Separation: This technique utilizes centrifugal force to separate phases, particularly effective for separating fine droplets.

- Membrane Separation: This method employs membranes to separate components based on their size or permeability, often used for gas purification.

1.6 Conclusion

The techniques described above work in tandem to effectively separate the oil, gas, and water phases from the produced fluid. Understanding these techniques is essential for optimizing production separator design and ensuring efficient separation.

Chapter 2: Models

2.1 Introduction

Production separator models provide a framework for understanding the separation process and predicting its performance. These models can be used to optimize separator design, predict separation efficiency, and analyze the impact of various operating conditions.

2.2 Empirical Models

These models rely on experimental data and empirical correlations to estimate separation efficiency. They are relatively simple to implement but may lack accuracy for complex separation scenarios.

- Stokes Law: Used to calculate the settling velocity of particles, providing insights into the separation of solid particles and liquid droplets.

- Two-Phase Flow Models: These models focus on the interaction between oil and gas phases, considering factors like pressure drop and flow patterns.

2.3 Computational Fluid Dynamics (CFD)

CFD models utilize numerical simulations to analyze fluid flow and separation within the separator. They offer detailed insights into flow patterns, pressure distribution, and separation efficiency.

- CFD software: Specialized software packages like ANSYS Fluent and STAR-CCM+ are used to perform CFD simulations.

- Advantages: High accuracy, detailed analysis of flow behavior, and optimization of separator design.

2.4 Artificial Neural Networks (ANN)

ANN models utilize machine learning algorithms to establish relationships between input parameters (e.g., flow rate, pressure, temperature) and output parameters (e.g., separation efficiency, water cut). They can learn complex patterns and improve prediction accuracy with experience.

2.5 Hybrid Models

These models combine different modeling techniques to leverage their strengths. For example, a hybrid model might use CFD to simulate flow behavior and empirical correlations to predict separation efficiency.

2.6 Conclusion

Production separator models provide valuable tools for understanding and optimizing the separation process. By understanding the principles behind these models, engineers can make informed decisions regarding separator design, operating conditions, and overall production efficiency.

Chapter 3: Software

3.1 Introduction

This chapter explores the various software tools available for designing, simulating, and analyzing production separators. These software applications aid in optimizing separator performance, ensuring efficient separation and reducing operational costs.

3.2 Design Software

- CAD Software: Programs like AutoCAD, SolidWorks, and Inventor allow for the detailed 3D modeling of production separators, facilitating visualization and design optimization.

- Piping Design Software: Tools like AutoPipe and PDMS are used for designing the piping systems connecting the separator to other production equipment.

3.3 Simulation Software

- CFD Software: As discussed in Chapter 2, CFD packages like ANSYS Fluent and STAR-CCM+ allow for the simulation of fluid flow and separation within the separator.

- Process Simulation Software: Programs like Aspen HYSYS and ProMax simulate the entire production process, including the separator, enabling optimization of the entire system.

3.4 Analysis Software

- Data Acquisition and Monitoring Software: Programs collect and analyze data from the separator's instrumentation, providing insights into its performance and potential issues.

- Statistical Analysis Software: Tools like Minitab and SPSS are used to analyze data trends and identify areas for improvement.

3.5 Specialized Software

- Separator Design Software: Specialized programs like SeparatorPro and SepSim are specifically designed for production separator design and analysis, offering features tailored to the task.

- Multiphase Flow Simulation Software: Software focusing on the complex interactions of oil, gas, and water phases can provide accurate predictions of separation performance.

3.6 Conclusion

Software tools play a vital role in modern production separator design and optimization. They offer capabilities ranging from 3D modeling and simulation to data analysis and performance monitoring, enabling engineers to ensure efficient operation and maximize resource utilization.

Chapter 4: Best Practices

4.1 Introduction

This chapter provides a set of best practices for optimizing production separator design, operation, and maintenance, ensuring efficient separation and maximizing production efficiency.

4.2 Design Considerations

- Proper Sizing: The separator should be adequately sized to handle the expected flow rate and fluid properties.

- Optimal Geometry: The separator's shape and internal components should be optimized for effective gravity settling and phase separation.

- Material Selection: The separator's materials should be corrosion resistant and withstand the operating conditions.

- Instrumentation: The separator should be equipped with appropriate instrumentation for monitoring pressure, temperature, fluid levels, and flow rates.

4.3 Operational Practices

- Maintain Optimal Operating Conditions: Ensure proper pressure and temperature control to facilitate efficient separation.

- Regular Monitoring and Control: Continuously monitor the separator's performance and take corrective actions when needed.

- Preventative Maintenance: Regular maintenance, including cleaning, inspection, and replacement of parts, is essential for reliable operation.

- Training and Expertise: Ensure that operators and maintenance personnel are properly trained to operate and maintain the separator effectively.

4.4 Maintenance Procedures

- Regular Inspections: Conduct periodic inspections to detect any potential issues, such as corrosion, leaks, or fouling.

- Cleaning and Removal of Fouling: Regularly clean the separator to remove accumulated solids, scale, and other fouling materials.

- Replacement of Worn Parts: Replace worn or damaged components promptly to avoid failures and maintain optimal performance.

- Documentation: Maintain comprehensive documentation of maintenance activities, inspections, and repairs.

4.5 Safety Considerations

- Pressure Relief Devices: The separator should be equipped with pressure relief valves to prevent overpressure conditions.

- Safety Procedures: Implement strict safety protocols for operating and maintaining the separator, minimizing risks to personnel.

- Emergency Response Plans: Establish clear emergency response plans for handling potential incidents.

4.6 Conclusion

By adhering to these best practices, operators can ensure that their production separators function effectively, contributing to efficient oil and gas production and minimizing environmental impact.

Chapter 5: Case Studies

5.1 Introduction

This chapter presents real-world case studies illustrating the impact of production separator design, operation, and maintenance on production efficiency and resource utilization.

5.2 Case Study 1: Optimization of Separator Design

- Problem: A production separator in a remote field was experiencing low separation efficiency, resulting in significant gas entrainment and reduced oil quality.

- Solution: A CFD simulation was conducted to analyze flow patterns and identify areas for improvement. The separator's internal baffles and mist eliminators were redesigned to enhance separation efficiency.

- Outcome: The redesign significantly reduced gas entrainment and improved oil quality, resulting in increased production and reduced operating costs.

5.3 Case Study 2: Implementing Best Practices for Maintenance

- Problem: A production separator in a mature field was experiencing frequent breakdowns due to corrosion and fouling.

- Solution: A comprehensive maintenance program was implemented, including regular inspections, cleaning, and replacement of worn parts.

- Outcome: The maintenance program significantly reduced downtime and increased separator reliability, improving production efficiency and extending the separator's lifespan.

5.4 Case Study 3: Utilizing Advanced Simulation Tools

- Problem: An oil company was planning a new production facility and needed to optimize separator design for specific fluid properties.

- Solution: Advanced simulation software, including CFD and process simulation tools, was used to analyze the separation process and optimize separator design for maximum efficiency.

- Outcome: The optimized separator design resulted in significantly improved separation efficiency, leading to increased oil production and reduced gas flaring.

5.5 Conclusion

These case studies demonstrate the importance of sound production separator design, operational practices, and maintenance strategies for maximizing production efficiency and resource utilization. By applying best practices and utilizing advanced tools, operators can ensure that their separators function effectively, contributing to sustainable oil and gas production.

- Bottom Hole Gas Separator Séparateur de Gaz de Fond de …

- mud-gas separator Séparateurs de boue-gaz : Out…

- Mud-Gas Separator Séparateurs de boue-gaz : gar…

- Commercial Production Level Niveau de production commerci…

- Critical Flow Rate (sand production) Débit Critique: Un Facteur Cl…

- Cumulative Production Production Cumulée : Suivre l…

- Dissolved Gas (production) Comprendre le Gaz Dissous (Pr…

- Flush Production Comprendre la production de d…

- Graded Production Acreage (GPA) Surface d'exploitation pondér…

- Deferred Production Production Différée : Un Drai…

- Dry Gas (in production) Gaz Sec : Comprendre les Fond…

- Entitlement (reserves/production) Droits d'exploitation (Réserv…

- Gas Production Unit Optimisation de la Production…

- Depreciation, Units of Production Amortissement : Unités de Pro…

- LOP (production) LOP : Un Voleur Silencieux da…

- Domestic production Production nationale : la lig…

- Filter Separator Garder le flux de gaz propre …

- Gas Lift Valve - Production Pressure Operated Valve (gas lift) Vanne de Soulèvement au Gaz :…

- Gross Production Production brute : un terme m…

- Held by Production Maintenir le Flux du Pétrole …

- Demande de justification des dépenses Naviguer dans la de… Planification et ordonnancement du projet

- Coût budgété du travail planifié Comprendre le Coût … Estimation et contrôle des coûts

- Les limites de batterie Comprendre les limi… Termes techniques généraux

- Outil DV Outil DV : Un éléme… Forage et complétion de puits

- SOMMAIRE TOC : Comprendre le… Termes techniques généraux

Comments