Forage et complétion de puits

Fann Viscometer

Le Viscosimètre Fann : Un Outil Essentiel pour les Opérations Pétrolières et Gazières

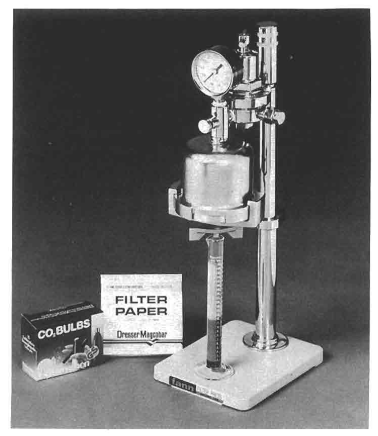

Le viscosimètre Fann est un instrument fondamental dans l'industrie pétrolière et gazière, servant d'outil fiable pour mesurer les propriétés rhéologiques des fluides de forage, des boues de cimentation et d'autres fluides de gisement pétrolier. Sa capacité à déterminer avec précision la viscosité dans des conditions variables le rend indispensable pour optimiser les opérations de forage, les processus de cimentation et l'efficacité globale de la production.

Qu'est-ce qu'un Viscosimètre Fann ?

Le viscosimètre Fann est un viscosimètre rotatif qui mesure la viscosité des fluides non newtoniens, comme les boues de forage et les boues de cimentation. Ces fluides présentent une viscosité variable en fonction de la contrainte de cisaillement appliquée. Contrairement aux fluides newtoniens, qui ont une viscosité constante, les fluides non newtoniens peuvent devenir plus fins ou plus épais avec l'augmentation du taux de cisaillement.

Comment ça fonctionne ?

Le viscosimètre Fann se compose d'un rotor (une broche cylindrique) immergé dans le fluide. Le rotor est relié à un arbre rotatif, qui est entraîné par un moteur. Le viscosimètre mesure le couple nécessaire pour faire tourner le rotor à une vitesse spécifique, qui est directement proportionnel à la viscosité du fluide. Ce couple est mesuré en unités de "Fann Units" (FU).

Applications clés dans le pétrole et le gaz :

- Opérations de forage :

- Optimisation du fluide : Le viscosimètre Fann permet de déterminer la viscosité optimale de la boue pour un forage efficace, garantissant un nettoyage adéquat du trou, la stabilité du trépan et la stabilité de la formation.

- Prévention de l'effondrement du trou : En ajustant la viscosité en fonction des pressions de formation, le viscosimètre Fann aide à prévenir l'instabilité du puits et un effondrement potentiel.

- Opérations de cimentation :

- Caractérisation de la boue : Le viscosimètre permet d'évaluer les propriétés rhéologiques des boues de cimentation, assurant une bonne fluidité et un bon placement dans le puits.

- Prévention de la formation de canaux : Il aide à concevoir des boues de cimentation qui minimisent la formation de canaux, assurant un travail de cimentation complet et efficace.

- Amélioration de la production :

- Analyse de l'écoulement du fluide : Le viscosimètre Fann permet d'évaluer le comportement d'écoulement des fluides produits, aidant à optimiser les taux de production et à minimiser les restrictions d'écoulement.

- Conception de l'équipement en fond de trou : En comprenant la rhéologie des fluides, les ingénieurs peuvent concevoir des équipements en fond de trou qui fonctionnent efficacement dans des conditions difficiles.

Avantages du viscosimètre Fann :

- Polyvalence : Le viscosimètre Fann peut mesurer une large gamme de viscosités, des faibles aux élevées.

- Fiabilité : Il fournit des résultats précis et constants, contribuant à une prise de décision fiable.

- Facilité d'utilisation : Il est relativement facile à utiliser, nécessitant une formation minimale.

- Portabilité : Le viscosimètre Fann est disponible en versions portables et de laboratoire, facilitant les mesures sur site et l'analyse rapide.

Résumé :

Le viscosimètre Fann joue un rôle essentiel pour garantir des opérations pétrolières et gazières sûres et efficaces. Sa capacité à mesurer avec précision la viscosité des fluides non newtoniens, associée à sa polyvalence et à sa convivialité, en fait un outil indispensable pour optimiser les processus de forage, de cimentation et de production. Son utilisation continue dans l'ensemble du secteur souligne sa valeur durable pour assurer une aventure pétrolière et gazière réussie et rentable.

Test Your Knowledge

Fann Viscometer Quiz:

Instructions: Choose the best answer for each question.

1. What type of fluids does the Fann Viscometer primarily measure? a) Newtonian fluids b) Non-Newtonian fluids c) Both Newtonian and non-Newtonian fluids d) Gaseous fluids

Answer

b) Non-Newtonian fluids

2. What is the unit of measurement for torque in a Fann Viscometer? a) Pascal (Pa) b) Newton (N) c) Fann Units (FU) d) Centipoise (cP)

Answer

c) Fann Units (FU)

3. Which of the following is NOT a key application of the Fann Viscometer in oil and gas operations? a) Optimizing drilling mud viscosity b) Characterizing cement slurry properties c) Determining the pressure of a reservoir d) Assessing the flow behavior of produced fluids

Answer

c) Determining the pressure of a reservoir

4. What is a significant advantage of the Fann Viscometer? a) It can only measure low viscosities. b) It is expensive and requires specialized training to operate. c) It is versatile and can measure a wide range of viscosities. d) It is only available in stationary laboratory models.

Answer

c) It is versatile and can measure a wide range of viscosities.

5. How does the Fann Viscometer measure viscosity? a) By measuring the time it takes for a specific volume of fluid to flow through a narrow tube. b) By measuring the resistance a rotating bob experiences in the fluid. c) By measuring the density of the fluid. d) By measuring the temperature of the fluid.

Answer

b) By measuring the resistance a rotating bob experiences in the fluid.

Fann Viscometer Exercise:

Scenario: You are working on a drilling operation and need to adjust the drilling mud viscosity. The current mud has a viscosity of 40 FU. The recommended viscosity for optimal hole cleaning and bit stability in this formation is between 25 FU and 35 FU.

Task: Describe the steps you would take to adjust the mud viscosity to the desired range using the Fann Viscometer. Include the specific actions you would take based on the current viscosity reading.

Exercice Correction

Here's a possible solution:

Analyze the current viscosity: The current mud viscosity of 40 FU is higher than the recommended range (25-35 FU). This indicates that the mud is too thick and might hinder efficient hole cleaning and bit stability.

Determine the adjustment needed: We need to reduce the viscosity by approximately 5-15 FU.

Identify the mud properties to adjust: There are several ways to reduce mud viscosity. You could:

- Add water: Diluting the mud with water will generally decrease viscosity.

- Adjust the barite content: Barite is a weighting material that increases density and viscosity. Reducing the barite content can lower the viscosity.

- Add a viscosity reducer: Chemicals like lignosulfonate or other viscosity reducers can effectively lower the mud viscosity.

Start with a small adjustment: Begin with a small change to the mud, like adding a small amount of water or reducing the barite by a small percentage.

Measure the viscosity after each adjustment: Use the Fann Viscometer to measure the mud viscosity after each adjustment. Document the results and the adjustments made.

Continue adjusting until the desired viscosity is achieved: Continue adjusting the mud properties in small increments, measuring the viscosity after each change until the viscosity falls within the desired range of 25-35 FU.

Monitor the mud viscosity: Once the desired viscosity is achieved, continue to monitor the mud viscosity throughout the drilling operation. Factors like drilling rate, formation pressures, and the amount of cuttings in the mud can affect viscosity, so adjustments might be necessary.

Books

- Drilling Fluids: Fundamentals and Applications by George R. Gray (This comprehensive book covers drilling fluid properties, including viscosity, and the role of the Fann viscometer in drilling operations.)

- Cementing: Fundamentals and Applications by H.C. Hsieh and R.B. Graham (This book explores cement slurry rheology and the importance of Fann viscometer measurements in cementing operations.)

- Reservoir Engineering Handbook by Tarek Ahmed (While not focused solely on Fann Viscometer, this book provides a broad understanding of fluid flow in reservoirs, where viscosity plays a crucial role.)

Articles

- "Rheological Properties of Drilling Fluids" by J.C. Jaeger (This article discusses the different types of drilling fluids and their rheological behavior, emphasizing the importance of Fann viscometer measurements.)

- "The Role of Rheology in Cementing Operations" by P.D. O'Brien (This article focuses on the application of rheology, including Fann Viscometer measurements, in optimizing cement slurry properties for successful cementing.)

- "Viscosity and Its Influence on Drilling Fluid Performance" by S.P. Sharma (This article details the impact of viscosity on drilling fluid performance, highlighting the significance of Fann viscometer measurements in optimizing drilling operations.)

Online Resources

- Fann Instrument Company Website: This website provides detailed information about Fann viscometers, their applications, and technical specifications. (https://www.fanninstruments.com/)

- API Recommended Practice 13B-1: Drilling Fluids (API, 2019): This industry standard provides guidance on drilling fluid properties, including viscosity measurements, and the use of the Fann viscometer.

- SPE Journal: This online journal frequently publishes articles related to drilling fluids, cementing, and reservoir engineering, often including information on rheology and Fann viscometer applications.

Search Tips

- "Fann Viscometer drilling fluids": This search will provide articles and resources specific to the use of Fann viscometer in drilling fluids.

- "Fann Viscometer cement slurry": This search will lead you to resources related to Fann viscometer applications in cementing operations.

- "Fann viscometer measurement techniques": This search will guide you to resources explaining the specific methods used for measuring viscosity with a Fann viscometer.

- "Fann viscometer calibration": This search will provide information on ensuring the accuracy of your Fann viscometer measurements through proper calibration.

Techniques

The Fann Viscometer: A Deep Dive

This document expands upon the introductory material provided, breaking down the information into distinct chapters for clarity.

Chapter 1: Techniques

The Fann viscometer employs a rotational method to determine the viscosity of fluids. The core technique involves measuring the torque required to rotate a bob (spindle) immersed in the test fluid at a pre-determined rotational speed. This torque is directly proportional to the fluid's viscosity. Several key techniques are crucial for accurate measurements:

- Sample Preparation: Proper sample preparation is critical. This includes ensuring the sample is homogenous, free of air bubbles (degassing may be necessary), and at the correct temperature. The temperature of the sample significantly impacts viscosity, therefore precise temperature control is essential, often using a temperature-controlled bath.

- Calibration: Regular calibration of the Fann viscometer is vital for maintaining accuracy. This involves using standard fluids of known viscosities to verify the instrument's readings. Calibration procedures should adhere strictly to the manufacturer's instructions.

- Measurement Procedure: A standardized procedure should be followed to ensure consistent and reliable results. This includes carefully immersing the bob in the sample, allowing for equilibration, and recording the torque readings at various speeds (typically 300 and 600 rpm for drilling muds). Multiple readings at each speed are usually taken and averaged.

- Data Interpretation: The obtained torque readings are converted into Fann Units (FU) using the instrument's calibration. These FU values, alongside other rheological parameters, provide insights into the fluid's behavior under different shear rates. Understanding the rheological model (discussed in the next chapter) is crucial for correct interpretation.

- Advanced Techniques: Techniques like yield point determination (using the Marsh funnel or other methods in conjunction with the Fann viscometer) and gel strength measurement expand the capabilities of the Fann viscometer in characterizing drilling fluids.

Chapter 2: Models

The Fann viscometer primarily measures apparent viscosity, which changes depending on the shear rate applied. To understand and predict the fluid's behavior under different conditions, several rheological models can be used in conjunction with the Fann viscometer data:

- Power-Law Model: This is a common model used to describe the non-Newtonian behavior of drilling fluids. It relates shear stress to shear rate using parameters like consistency index (K) and flow behavior index (n). The Fann viscometer data provides the necessary measurements to determine these parameters.

- Bingham Plastic Model: This model represents fluids with a yield stress, meaning they behave as a solid until a certain stress is exceeded. The Fann viscometer data can be used to determine the yield stress and plastic viscosity.

- Herschel-Bulkley Model: This is a more complex model incorporating both yield stress and a shear-thinning behavior. This is a more accurate representation for some drilling fluids.

These models help predict the fluid’s behavior under various conditions, aiding in designing optimal drilling and cementing fluids. The choice of model depends on the specific fluid type and its rheological characteristics.

Chapter 3: Software

Modern Fann viscometers often come with integrated software or are compatible with software packages that automate data acquisition, analysis, and reporting. These software packages offer various features:

- Data Logging and Storage: Automated recording and storage of viscosity readings at various speeds and temperatures.

- Rheological Model Fitting: Software can fit the collected data to different rheological models (Power-law, Bingham Plastic, Herschel-Bulkley) to determine model parameters.

- Report Generation: Automatic generation of reports containing viscosity curves, model parameters, and other relevant information.

- Data Export: Exporting data to other software for further analysis and integration with other drilling or production management systems.

- Quality Control: Some software packages include features for quality control, flagging potential errors or outliers in the data.

The choice of software depends on the specific Fann viscometer model and the user's needs. Advanced software packages can significantly improve efficiency and data analysis capabilities.

Chapter 4: Best Practices

To ensure accurate and reliable results, several best practices should be followed when using a Fann viscometer:

- Regular Calibration: Regular calibration using certified standard fluids is crucial for maintaining accuracy. The frequency of calibration depends on the usage intensity and should be documented.

- Proper Cleaning and Maintenance: The viscometer should be cleaned thoroughly after each use to prevent cross-contamination and maintain its integrity. Regular maintenance, following the manufacturer’s guidelines, is essential for prolonging its lifespan.

- Temperature Control: Maintaining a constant temperature during measurements is critical as temperature significantly impacts viscosity. Use of a temperature-controlled bath is recommended.

- Standardized Procedures: Adherence to standardized operating procedures ensures consistency and reproducibility of results. These procedures should be documented and followed rigorously.

- Operator Training: Proper training of operators is essential to ensure accurate measurements and data interpretation. Training should include both theoretical and practical aspects of using the Fann viscometer.

- Data Management: Proper data management practices are crucial for traceability and future reference. Data should be stored securely and systematically.

Chapter 5: Case Studies

(This chapter requires specific examples of Fann viscometer applications. The following are illustrative examples and would need to be replaced with real-world case studies.)

- Case Study 1: Optimizing Drilling Mud Rheology: A drilling operation experienced difficulties with hole cleaning and wellbore instability. By using a Fann viscometer to carefully adjust the drilling mud rheology, the team optimized the mud's viscosity and yield point, resulting in improved hole cleaning and reduced risk of wellbore instability, leading to significant cost savings and improved drilling efficiency.

- Case Study 2: Ensuring Effective Cementing: In a challenging wellbore environment, a cementing operation utilized a Fann viscometer to analyze the rheological properties of the cement slurry. This analysis ensured that the slurry had the optimal rheology for proper placement and prevented channeling, leading to a successful cement job and avoiding costly remedial work.

- Case Study 3: Analyzing Produced Fluids: In an oil production scenario, the Fann viscometer helped analyze the flow behavior of produced fluids, identifying potential flow restrictions and contributing to the optimization of production rates and reduced downtime.

These case studies highlight the practical applications of the Fann viscometer and its contribution to improved efficiency and safety in oil and gas operations. Further examples could demonstrate its use in specific formations, with different drilling fluids, or in specific well completion scenarios.

- Fanning Equation (or friction factor) Comprendre les Pertes de Char…

- Demande de justification des dépenses Naviguer dans la de… Planification et ordonnancement du projet

- Coût budgété du travail planifié Comprendre le Coût … Estimation et contrôle des coûts

- Les limites de batterie Comprendre les limi… Termes techniques généraux

- Outil DV Outil DV : Un éléme… Forage et complétion de puits

- SOMMAIRE TOC : Comprendre le… Termes techniques généraux

Comments