Forage et complétion de puits

permeability

Perméabilité : La Clé du Flux de Fluides dans le Forage et l'Achèvement de Puits

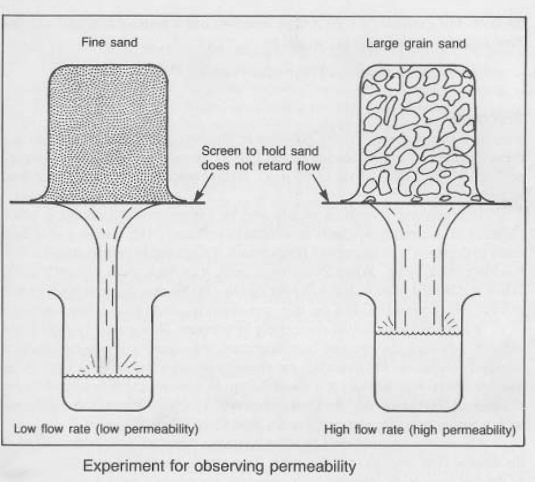

La perméabilité est un concept crucial dans l'industrie pétrolière et gazière, en particulier dans le forage et l'achèvement de puits. Elle fait référence à la **facilité avec laquelle les fluides peuvent circuler à travers les espaces poreux interconnectés dans une formation rocheuse ou un ciment**. Comprendre la perméabilité est essentiel pour prédire les performances du réservoir, concevoir des compléments de puits efficaces et optimiser la production.

Qu'est-ce que la perméabilité ?

En termes plus simples, la perméabilité est la **conductivité des fluides d'un milieu poreux**. Imaginez une formation rocheuse comme une éponge. Les pores à l'intérieur de la roche représentent les trous de l'éponge. La perméabilité mesure la facilité avec laquelle les fluides comme le pétrole, le gaz ou l'eau peuvent se déplacer à travers ces pores interconnectés sous pression.

Mesurer la perméabilité :

L'unité standard de mesure de la perméabilité est le **millidarcy (mD)**. Un darcy est une très grande unité, donc les millidarcys sont plus couramment utilisés. Une valeur en millidarcys plus élevée indique une perméabilité plus élevée, ce qui signifie que les fluides peuvent circuler plus facilement à travers la formation.

Pourquoi la perméabilité est-elle importante ?

La perméabilité joue un rôle essentiel dans divers aspects du forage et de l'achèvement de puits :

- Caractérisation du réservoir : La perméabilité permet de déterminer la capacité d'un réservoir à produire des hydrocarbures. Les formations à haute perméabilité permettent une circulation plus facile des fluides, ce qui se traduit par des taux de production plus élevés.

- Conception de l'achèvement du puits : La compréhension de la perméabilité de la formation guide la conception des compléments de puits, tels que le choix de la taille et de l'espacement des perforations, qui visent à maximiser la production.

- Opérations de fracturation : Dans les formations à faible perméabilité, la fracturation hydraulique est souvent utilisée pour créer des voies artificielles permettant aux fluides de circuler. Les données de perméabilité sont essentielles pour optimiser les conceptions de fracturation.

- Cimentage : La perméabilité du ciment utilisé pour sceller les puits influence le flux de fluide et le risque de problèmes d'intégrité du puits.

Facteurs affectant la perméabilité :

Plusieurs facteurs influencent la perméabilité d'une formation, notamment :

- Taille et forme des pores : Des pores plus grands et plus interconnectés conduisent à une perméabilité plus élevée.

- Connectivité des pores : Des pores bien connectés permettent une circulation plus facile des fluides.

- Composition minérale : Différents minéraux présentent des degrés de perméabilité variables.

- Pression de formation : Une pression plus élevée peut augmenter la perméabilité.

En conclusion :

La perméabilité est un concept fondamental dans le forage et l'achèvement de puits, influençant les performances du réservoir, les conceptions d'achèvement de puits et l'optimisation de la production. En comprenant et en utilisant les données de perméabilité, l'industrie pétrolière et gazière peut extraire efficacement les hydrocarbures et maximiser son potentiel de production.

Test Your Knowledge

Permeability Quiz

Instructions: Choose the best answer for each question.

1. What does permeability measure? a) The amount of fluid a rock can hold.

Answer

Incorrect. This describes porosity.

Answer

Correct!

Answer

Incorrect. This describes porosity.

Answer

Incorrect. This is related to permeability but not the direct measurement.

2. What is the standard unit of measurement for permeability? a) Milliliter (mL)

Answer

Incorrect. This is a unit of volume.

Answer

Incorrect. This is a unit of length.

Answer

Correct!

Answer

Incorrect. This is a unit of pressure.

3. Which of the following factors influences permeability? a) Pore size and shape.

Answer

Correct!

Answer

Correct!

Answer

Correct!

Answer

Correct! All of the options influence permeability.

4. How does high permeability impact reservoir performance? a) It results in lower production rates.

Answer

Incorrect. High permeability allows for easier fluid flow.

Answer

Incorrect. High permeability makes extraction easier.

Answer

Correct!

Answer

Incorrect. Permeability is a crucial factor for reservoir performance.

5. In low-permeability formations, what technique is often used to enhance fluid flow? a) Well completion design.

Answer

Incorrect. While important, well completion design alone doesn't address low permeability.

Answer

Correct!

Answer

Incorrect. Cementing aims to seal wellbores.

Answer

Incorrect. Hydraulic fracturing is used to enhance flow in low-permeability formations.

Permeability Exercise

Scenario: You are an engineer working on a new oil well project. The reservoir has been identified with a permeability of 50 mD.

Task: Explain how this permeability value influences your decisions regarding:

- Well completion design:

- Fracturing operations:

- Expected production rate:

Provide a brief justification for each decision.

Exercise Correction

**Well completion design:** A permeability of 50 mD suggests a moderately permeable reservoir. You might choose to use a well completion design that optimizes for fluid flow, potentially including larger perforation sizes and/or closer spacing to enhance production. **Fracturing operations:** A permeability of 50 mD might not warrant hydraulic fracturing. Fracturing is typically employed in low-permeability formations (< 10 mD). However, further analysis of the reservoir characteristics and production targets would be needed to determine the necessity of fracturing. **Expected production rate:** The permeability value indicates a reasonable expectation of production. While not exceptionally high, it suggests a good flow potential. However, the expected production rate will depend on other factors like porosity, reservoir size, and fluid properties, and requires further analysis.

Books

- Fundamentals of Reservoir Engineering by John C. Lee (Covers permeability concepts in detail)

- Petroleum Engineering Handbook by Tarek Ahmed (Comprehensive resource on reservoir engineering, including permeability)

- Introduction to Petroleum Engineering by Don. O. Egbogah (Basic introduction to permeability and its significance)

- The Properties of Petroleum Fluids by William E. McCain, Jr. (Focuses on fluid flow properties, including permeability)

Articles

- "Permeability: A Key Parameter in Reservoir Engineering" by Society of Petroleum Engineers (Provides overview and importance of permeability)

- "A Comprehensive Review of Permeability Measurement Techniques" by Journal of Petroleum Science and Engineering (Discusses various methods for determining permeability)

- "The Impact of Permeability on Well Completion Design" by SPE Journal (Explores the relationship between permeability and well completion)

- "Permeability Anisotropy: A Review of Its Significance in Reservoir Modeling" by Journal of Geophysics and Engineering (Examines the complexity of permeability in heterogeneous formations)

Online Resources

- SPE (Society of Petroleum Engineers): https://www.spe.org/ - Offers a vast collection of technical papers and resources on reservoir engineering and permeability.

- Schlumberger: https://www.slb.com/ - Provides information on various drilling and well completion technologies, including permeability assessment.

- Halliburton: https://www.halliburton.com/ - Offers similar resources to Schlumberger on well completion and reservoir characterization.

- Wikipedia: https://en.wikipedia.org/wiki/Permeability - Provides a general overview of permeability and its applications.

Search Tips

- Specific terms: "permeability measurement", "permeability calculation", "permeability anisotropy", "permeability modeling", "permeability data interpretation"

- Combine with industry: "permeability oil and gas", "permeability reservoir characterization", "permeability well completion design"

- Add location: "permeability shale formations", "permeability Middle East reservoirs", "permeability North Sea"

Techniques

Chapter 1: Techniques for Measuring Permeability

This chapter delves into the methods used to determine the permeability of rock formations, providing insights into their principles, applications, and limitations.

1.1 Laboratory Methods:

Core Analysis: This classic method involves extracting core samples from the wellbore and measuring their permeability in a laboratory setting. Various techniques exist, including:

- Steady-State Flow: A constant pressure gradient is applied across the core sample, and the flow rate is measured to calculate permeability.

- Unsteady-State Flow: A transient pressure pulse is applied to the core, and the pressure response is analyzed to determine permeability.

- Pulse Decay: This technique involves injecting a pulse of fluid into the core and measuring the time it takes for the pressure to decay, providing a measure of permeability.

Permeability Measurement on Cuttings: While less accurate than core analysis, this method utilizes cuttings obtained during drilling operations to provide an estimate of permeability. Techniques like the Klinkenberg method can be used to account for gas slip effects.

1.2 Field Methods:

- Production Logging: This technique analyzes pressure and flow rate data from producing wells to estimate reservoir permeability. Various tools, such as permeability probes and nuclear magnetic resonance (NMR) logs, can be used to obtain this information.

- Well Test Analysis: Analyzing pressure transient data obtained during well tests can provide valuable information about reservoir permeability, as well as other reservoir properties.

- Downhole Permeability Measurement: Specialized tools, such as formation testers and mini-frac tools, can be deployed downhole to measure permeability in the formation directly. These tools utilize various techniques, like pressure buildup and decay, to obtain permeability measurements.

1.3 Limitations of Permeability Measurements:

- Sample Representativeness: Core samples and cuttings may not accurately represent the entire reservoir.

- Laboratory vs. Field Conditions: Permeability measurements conducted in a lab may differ from actual reservoir conditions due to pressure, temperature, and fluid saturation variations.

- Heterogeneity: Reservoirs are often heterogeneous, meaning permeability can vary significantly within the formation, making it challenging to obtain representative measurements.

1.4 Conclusion:

The choice of permeability measurement technique depends on factors like wellbore accessibility, available technology, and the desired accuracy. Understanding the limitations of each technique is crucial for interpreting the results and making informed decisions about reservoir development and production.

Chapter 2: Models for Permeability Prediction

This chapter explores various models used to predict permeability in the absence of direct measurements, providing valuable tools for reservoir characterization and development.

2.1 Empirical Models:

- Kozeny-Carman Equation: This widely used model relates permeability to pore size, porosity, and tortuosity, allowing for permeability prediction based on these parameters.

- Hazen's Equation: Primarily used for unconsolidated sands, this equation predicts permeability based on grain size distribution.

- Empirical Correlation Models: These models are based on statistical relationships between permeability and other reservoir properties, such as porosity, grain density, and mineralogy.

2.2 Petrophysical Models:

- Pore Network Modeling: This approach utilizes computer simulation to generate a virtual representation of the pore network within a rock sample. By simulating fluid flow through the virtual network, permeability can be predicted.

- Fractal Modeling: This technique uses fractal geometry to describe the complex pore structure of rocks, leading to accurate permeability predictions for highly heterogeneous formations.

- Geostatistical Modeling: This method utilizes statistical techniques to estimate the spatial distribution of permeability within a reservoir based on available data points.

2.3 Fluid Flow Simulation:

- Numerical Reservoir Simulation: This approach utilizes complex computer models to simulate fluid flow through a reservoir, taking into account permeability distribution and other reservoir parameters. The results can be used to predict production behavior and optimize well placement.

2.4 Conclusion:

Permeability prediction models provide essential tools for evaluating reservoir potential and designing production strategies. While each model has its strengths and limitations, they offer valuable insights into the fluid flow characteristics of reservoirs, ultimately aiding in the efficient development of hydrocarbon resources.

Chapter 3: Software for Permeability Analysis

This chapter highlights the software tools commonly used in the oil and gas industry for analyzing permeability data, facilitating informed decision-making for reservoir development and production.

3.1 Core Analysis Software:

- PetroMod: This software package provides comprehensive analysis capabilities for core data, including permeability measurements, porosity determination, and fluid saturation analysis.

- CoreLab: A versatile tool for core analysis, CoreLab offers various functionalities, including permeability calculation, porosity assessment, and visualization of core data.

- RockWare: This software provides a suite of tools for analyzing rock properties, including permeability, porosity, and grain size distribution, enabling comprehensive reservoir characterization.

3.2 Well Log Analysis Software:

- Techlog: This software is widely used for analyzing well log data, including permeability logs, porosity logs, and nuclear magnetic resonance (NMR) logs, providing insights into reservoir properties.

- Petrel: A comprehensive reservoir modeling and simulation software, Petrel offers powerful tools for analyzing well logs, including permeability data, for building accurate reservoir models.

- Landmark DecisionSpace: This software suite enables integrated reservoir analysis, encompassing well log interpretation, permeability modeling, and fluid flow simulation.

3.3 Reservoir Simulation Software:

- ECLIPSE: A leading software for reservoir simulation, ECLIPSE allows for modeling fluid flow in complex reservoirs, taking into account permeability distribution and other reservoir properties.

- CMG STARS: Another popular reservoir simulation software, CMG STARS provides advanced capabilities for simulating fluid flow in various reservoir scenarios, including heterogeneous permeability distributions.

- INTERSECT: This software focuses on wellbore and reservoir simulation, enabling accurate modeling of fluid flow in the vicinity of wells, considering permeability variations in the formation.

3.4 Open-Source Software:

- OpenFOAM: A powerful open-source computational fluid dynamics (CFD) package, OpenFOAM allows for advanced simulation of fluid flow through porous media, providing detailed insights into permeability-related phenomena.

- GOCAD: This open-source software is widely used for geological modeling, including permeability modeling and visualization, offering a valuable tool for reservoir characterization.

3.5 Conclusion:

Software plays a vital role in analyzing permeability data, facilitating informed decision-making for reservoir development and production. From core analysis to well log interpretation and reservoir simulation, specialized software tools offer powerful capabilities for understanding the fluid flow characteristics of reservoirs and optimizing production strategies.

Chapter 4: Best Practices for Permeability Analysis

This chapter provides insights into the best practices for conducting permeability analysis, ensuring accuracy, reliability, and informed decision-making.

4.1 Data Quality and Integrity:

- Accurate Measurements: Ensure high-quality permeability measurements through rigorous laboratory procedures and proper calibration of instruments.

- Data Validation: Verify the consistency and accuracy of permeability data by comparing results from different methods and validating against other reservoir properties.

- Data Management: Implement a robust data management system to ensure data integrity, traceability, and efficient retrieval.

4.2 Reservoir Characterization:

- Understanding Geology: Thoroughly investigate the geological setting of the reservoir, including formation type, depositional environment, and structural features, to inform permeability analysis.

- Integrating Data: Combine permeability data from various sources, such as core analysis, well logs, and production data, to obtain a holistic understanding of permeability distribution.

- Spatial Variability: Recognize the spatial variability of permeability within the reservoir and use appropriate statistical and geostatistical techniques to model its distribution.

4.3 Well Completion Design:

- Optimizing Perforations: Design perforations based on permeability characteristics of the formation to maximize production rates and minimize damage.

- Fracturing Optimization: Utilize permeability data to optimize hydraulic fracturing design, ensuring effective stimulation of low-permeability formations.

- Well Placement: Consider permeability distribution when selecting well locations to maximize production and minimize water or gas breakthrough.

4.4 Production Management:

- Monitoring Performance: Track production data and analyze permeability changes over time to assess reservoir performance and identify potential issues.

- Reservoir Modeling: Develop realistic reservoir models incorporating permeability data to predict future production behavior and optimize production strategies.

- Decision-Making: Use permeability information to make informed decisions about production optimization, well intervention, and future development plans.

4.5 Conclusion:

Adhering to best practices in permeability analysis ensures accuracy, reliability, and informed decision-making for reservoir development and production. By integrating data from various sources, understanding spatial variability, and utilizing software tools effectively, the oil and gas industry can optimize production, maximize resource recovery, and minimize risks.

Chapter 5: Case Studies of Permeability in Drilling & Well Completion

This chapter explores real-world examples of how permeability plays a critical role in various aspects of drilling and well completion, showcasing its practical implications in the oil and gas industry.

5.1 Case Study 1: Optimizing Perforations in a Tight Gas Reservoir

- Scenario: A tight gas reservoir with low permeability poses challenges for production.

- Challenge: Design perforation patterns to maximize gas flow and optimize production rates.

- Solution: Analyzing permeability data from core analysis and well logs, engineers optimized perforation size and spacing to create efficient flow pathways, leading to significant production increase.

5.2 Case Study 2: Hydraulic Fracturing in a Shale Oil Play

- Scenario: A shale oil reservoir with extremely low permeability requires stimulation for production.

- Challenge: Design effective hydraulic fracturing stages to create extensive fracture networks and enhance oil flow.

- Solution: By analyzing permeability data, engineers targeted specific zones with higher permeability for fracturing, maximizing the effectiveness of the stimulation process and achieving high production rates.

5.3 Case Study 3: Predicting Reservoir Performance Using Permeability Modeling

- Scenario: Evaluating the potential of a new discovery and predicting its production behavior.

- Challenge: Assess the reservoir's productivity based on limited permeability data.

- Solution: Using geostatistical modeling, engineers created a 3D representation of the reservoir's permeability distribution, enabling the prediction of fluid flow patterns and overall reservoir performance.

5.4 Case Study 4: Identifying and Mitigating Wellbore Damage

- Scenario: Production decline in a mature well due to potential wellbore damage.

- Challenge: Determine the cause of production decline and implement appropriate mitigation strategies.

- Solution: Analyzing permeability data from well logs and production history, engineers identified a zone of reduced permeability near the wellbore, suggesting formation damage. They then used acid stimulation to remove the damage and restore production.

5.5 Conclusion:

These case studies demonstrate the diverse applications of permeability analysis in drilling and well completion, showcasing its importance in optimizing production, maximizing resource recovery, and mitigating risks. By leveraging permeability data, the oil and gas industry can make informed decisions and achieve better outcomes in reservoir development and production.

- Directional Permeability Perméabilité Directionnelle :…

- Effective Permeability Perméabilité Effective : Un C…

- Klinkenberg Permeability Décryptage des secrets du flu…

- Permeability Barrier Barrières de Perméabilité : L…

- Permeability Contrast Contraste de perméabilité : u…

- Permeability Correlation Corrélation de Perméabilité …

- Permeability or k Débloquer le flux : La perméa…

- Pressure Dependent Permeability Perméabilité Dépendante de la…

- Pressure Dependent Permeability La Nature Dynamique de la Per…

- Relative Permeability Perméabilité Relative : Navig…

- Relative Permeability Modifiers L'épée à double tranchant des…

- Return Permeability Perméabilité de Retour : Débl…

- Demande de justification des dépenses Naviguer dans la de… Planification et ordonnancement du projet

- Coût budgété du travail planifié Comprendre le Coût … Estimation et contrôle des coûts

- Les limites de batterie Comprendre les limi… Termes techniques généraux

- Outil DV Outil DV : Un éléme… Forage et complétion de puits

- SOMMAIRE TOC : Comprendre le… Termes techniques généraux

Comments