Purification de l'eau

pressure filtration

Filtration sous Pression : Un Outil Puissant pour l'Eau Propre

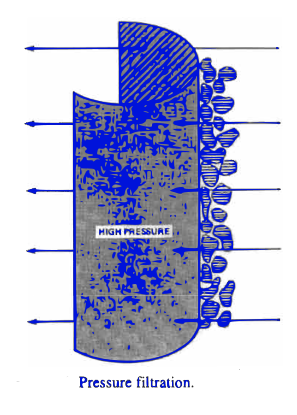

Dans le domaine de l'environnement et du traitement de l'eau, la filtration sous pression s'impose comme une technologie essentielle pour éliminer les solides indésirables des liquides. Ce procédé, comme son nom l'indique, utilise une pression externe pour forcer le liquide à traverser un milieu filtrant, séparant ainsi les particules solides du liquide propre.

Les Bases de la Filtration sous Pression

Imaginez que vous pressez une éponge imbibée d'eau sale. La pression que vous exercez force l'eau à traverser l'éponge, laissant la saleté derrière elle. Cette simple analogie capture l'essence de la filtration sous pression. En pratique, l'« éponge » est remplacée par un milieu filtrant, qui peut aller de matériaux granulaires comme le sable et le gravier à des membranes spécialisées.

La force motrice derrière cette séparation est le différentiel de pression. Une pompe ou une autre source externe crée une pression plus élevée du côté de l'eau sale du filtre, poussant le liquide à travers le milieu filtrant. Le milieu filtrant lui-même est conçu pour capturer des particules d'une taille spécifique, permettant à l'eau propre de passer.

Pourquoi la Filtration sous Pression est Importante

La filtration sous pression joue un rôle crucial dans diverses applications environnementales et de traitement de l'eau :

- Traitement de l'eau potable municipale : Élimination des solides en suspension, de la turbidité et d'autres contaminants de l'eau potable.

- Traitement des eaux usées industrielles : Traitement des eaux usées industrielles pour respecter les limites de rejet réglementaires et protéger les ressources en eau.

- Traitement de l'eau des piscines et des spas : Maintien de conditions d'eau propres et hygiéniques.

- Transformation des aliments et des boissons : Clarification et purification des boissons, des jus et d'autres produits alimentaires.

- Fabrication pharmaceutique : Production d'eau de haute qualité pour les processus pharmaceutiques.

Types de Systèmes de Filtration sous Pression

Il existe divers systèmes de filtration sous pression, chacun étant adapté à des applications et des exigences spécifiques en matière d'élimination des contaminants.

- Filtres à sable : Utilisent des lits de sable pour capturer les particules plus grosses. Ils sont couramment utilisés pour le traitement de l'eau potable et des eaux usées.

- Filtres à cartouche : Utilisent des cartouches jetables contenant un milieu filtrant comme le polypropylène, le charbon actif ou d'autres matériaux pour éliminer des contaminants spécifiques.

- Filtres à membrane : Utilisent des membranes semi-perméables avec des pores microscopiques pour éliminer même les plus petites particules, les bactéries et les virus.

- Filtres à terre de diatomées : Utilisent un matériau poreux à base de silice appelé terre de diatomées pour filtrer les solides en suspension.

Avantages de la Filtration sous Pression

- Haute efficacité : Les systèmes de filtration sous pression peuvent atteindre des niveaux élevés d'élimination des solides.

- Conception compacte : Ces systèmes peuvent être conçus pour s'adapter à des espaces restreints.

- Fonctionnement automatique : De nombreux systèmes fonctionnent automatiquement, nécessitant une intervention humaine minimale.

- Applications polyvalentes : Adapté au traitement d'une large gamme de sources d'eau et de contaminants.

Défis et Considérations

Malgré ses avantages, la filtration sous pression présente certains défis :

- Remplacement du milieu filtrant : Le milieu filtrant doit être remplacé ou nettoyé régulièrement, ce qui ajoute des coûts opérationnels.

- Chute de pression : La chute de pression à travers le filtre peut augmenter avec le temps, affectant l'efficacité.

- Prétraitement : Des étapes de prétraitement peuvent être nécessaires pour éliminer les particules plus grosses et protéger le milieu filtrant.

Conclusion

La filtration sous pression est un outil puissant dans la boîte à outils de l'environnement et du traitement de l'eau. Elle joue un rôle essentiel dans la garantie d'une eau propre pour la boisson, les processus industriels et les loisirs. La compréhension des principes de la filtration sous pression et de ses diverses applications est cruciale pour concevoir des systèmes de traitement de l'eau efficaces et durables.

Test Your Knowledge

Pressure Filtration Quiz

Instructions: Choose the best answer for each question.

1. What is the driving force behind pressure filtration? (a) Gravity (b) Pressure differential (c) Temperature difference (d) Magnetic attraction

Answer

The correct answer is (b) Pressure differential.

2. Which of the following is NOT a type of pressure filtration system? (a) Sand filter (b) Cartridge filter (c) Centrifuge filter (d) Membrane filter

Answer

The correct answer is (c) Centrifuge filter.

3. Pressure filtration is commonly used in which of the following applications? (a) Municipal water treatment (b) Industrial wastewater treatment (c) Swimming pool water treatment (d) All of the above

Answer

The correct answer is (d) All of the above.

4. What is a significant advantage of pressure filtration? (a) Low energy consumption (b) High efficiency in solid removal (c) No need for pre-treatment (d) No filter media replacement required

Answer

The correct answer is (b) High efficiency in solid removal.

5. What is a major challenge associated with pressure filtration? (a) Limited application range (b) High maintenance costs (c) Inefficient operation (d) Environmental pollution

Answer

The correct answer is (b) High maintenance costs.

Pressure Filtration Exercise

Scenario: You are tasked with choosing the best pressure filtration system for a small-scale industrial wastewater treatment plant. The wastewater contains suspended solids, oils, and some dissolved organic matter. The treatment plant needs to be cost-effective and have a high removal efficiency.

Task:

- Based on the information provided, identify two suitable pressure filtration systems from the list below.

- Justify your choices by explaining how each system addresses the specific contaminants and requirements of the treatment plant.

- List one potential challenge for each chosen system and suggest a solution.

List of Pressure Filtration Systems: * Sand filter * Cartridge filter * Membrane filter * Diatomaceous Earth filter

Exercise Correction

Here is a possible solution:

1. Suitable pressure filtration systems: * Sand filter: Can effectively remove suspended solids. * Cartridge filter (with activated carbon): Can remove both suspended solids and dissolved organic matter, with the activated carbon component.

2. Justification: * Sand filter: Ideal for removing the suspended solids in the wastewater. It is relatively inexpensive and easy to operate. * Cartridge filter (with activated carbon): Addresses the dissolved organic matter in the wastewater and also captures suspended solids. Activated carbon offers additional contaminant removal.

3. Potential challenges and solutions: * Sand filter: May require frequent backwashing to maintain efficiency. * Solution: Implement a backwashing system to clean the sand bed regularly. * Cartridge filter: Cartridge replacement costs can be significant. * Solution: Choose a cartridge material that is durable and can withstand repeated cleaning, minimizing replacement frequency.

Books

- "Water Treatment Plant Design" by AWWA (American Water Works Association) - A comprehensive guide covering various aspects of water treatment, including pressure filtration.

- "Membrane Filtration Handbook" by Michael Mulder - A detailed resource on membrane filtration, which is a type of pressure filtration, covering various applications and technologies.

- "Handbook of Separation Process Technology" by Ronald W. Rousseau - A broad overview of separation processes, including filtration techniques.

Articles

- "Pressure Filtration: A Review" by A. K. Jain and S. K. Gupta (Journal of Environmental Engineering & Science, 2007) - A review article discussing the fundamentals, applications, and challenges of pressure filtration.

- "Pressure Filtration for Drinking Water Treatment" by J. S. Davis (Journal of the American Water Works Association, 2002) - A specific focus on pressure filtration in the context of drinking water treatment.

- "A Review of Pressure Filtration in Wastewater Treatment" by M. A. Khan and R. A. Khan (Journal of Environmental Management, 2015) - An overview of pressure filtration for wastewater treatment, highlighting different technologies and applications.

Online Resources

- American Water Works Association (AWWA): https://www.awwa.org/ - AWWA provides resources, standards, and publications on water treatment technologies, including pressure filtration.

- Water Environment Federation (WEF): https://www.wef.org/ - WEF offers information on wastewater treatment, including pressure filtration systems and their applications.

- National Institute of Health (NIH): https://www.ncbi.nlm.nih.gov/ - NIH's PubMed database provides access to scientific research articles, including those related to pressure filtration.

- Environmental Protection Agency (EPA): https://www.epa.gov/ - The EPA website contains information on water quality standards and treatment technologies, including pressure filtration.

Search Tips

- Use specific keywords like "pressure filtration," "sand filtration," "cartridge filtration," "membrane filtration," "diatomaceous earth filtration," followed by the application area (e.g., "drinking water," "wastewater," "industrial").

- Combine keywords with relevant terms like "applications," "technologies," "advantages," "disadvantages," "cost," "efficiency," "design," "operation," and "maintenance."

- Use quotation marks around specific phrases for precise results (e.g., "pressure filtration systems").

- Use the "filetype" operator to find PDF documents (e.g., "pressure filtration filetype:pdf") or other document types.

- Utilize advanced search options in Google to refine your results (e.g., specific date range, website, language).

Techniques

Chapter 1: Techniques of Pressure Filtration

Pressure filtration encompasses various techniques, each employing different mechanisms and filter media for efficient solid separation. Here's a closer look at some prominent techniques:

1.1 Sand Filtration:

- Mechanism: Sand filters utilize a bed of graded sand to trap suspended particles. Water flows through the sand bed, with larger particles trapped at the top layers and finer particles captured deeper in the bed.

- Applications: Widely used in municipal water treatment, wastewater treatment, and swimming pool filtration.

- Advantages: Relatively inexpensive, effective at removing suspended solids, easily backwashable to regenerate the filter bed.

- Limitations: Not effective for removing very fine particles or dissolved contaminants.

1.2 Cartridge Filtration:

- Mechanism: Cartridge filters employ disposable cartridges containing various filter media like polypropylene, activated carbon, or membrane materials. These cartridges capture suspended solids and specific contaminants based on the chosen media.

- Applications: Wide range of applications, from water purification to food and beverage processing.

- Advantages: High efficiency, convenient for replacing cartridges, available in various sizes and filter ratings.

- Limitations: Disposable cartridges generate waste, can be expensive for large-scale applications.

1.3 Membrane Filtration:

- Mechanism: Membrane filters use semi-permeable membranes with precisely sized pores to remove particles, bacteria, viruses, and other contaminants.

- Types: Microfiltration (MF), Ultrafiltration (UF), Nanofiltration (NF), Reverse Osmosis (RO). Each type has different pore sizes, allowing for targeted removal of specific contaminants.

- Applications: Water purification, pharmaceutical manufacturing, food processing, and wastewater treatment.

- Advantages: High removal efficiency, able to remove a wide range of contaminants, can be used for water softening and desalination.

- Limitations: Membrane fouling can reduce efficiency, requires specific operating conditions and pre-treatment steps.

1.4 Diatomaceous Earth Filtration:

- Mechanism: Diatomaceous earth (DE) filters use a porous, silica-based material known as diatomaceous earth as the filter medium. A thin cake of DE is formed on the filter surface, capturing suspended solids.

- Applications: Commonly used in municipal water treatment, industrial wastewater treatment, and food processing.

- Advantages: High efficiency, relatively low cost, can be used for a wide range of flow rates.

- Limitations: DE is a hazardous material and requires careful handling, can be difficult to clean and regenerate.

1.5 Other Techniques:

- Ceramic Filters: Employ ceramic materials with pores to remove contaminants.

- Activated Carbon Filters: Utilize activated carbon to adsorb dissolved organic compounds and improve taste and odor.

Understanding these different techniques is crucial for selecting the appropriate pressure filtration system for specific water treatment needs.

Chapter 2: Models of Pressure Filtration Systems

Pressure filtration systems come in various models, each tailored for specific applications and requirements. Here's a breakdown of some prominent models:

2.1 Single-Stage Filtration:

- Description: This model uses a single filter unit to remove contaminants. The water flows through the filter medium and exits as the clean water.

- Advantages: Simple design, relatively low cost, suitable for small-scale applications.

- Limitations: Not ideal for removing a wide range of contaminants, may require frequent filter replacements.

2.2 Multi-Stage Filtration:

- Description: This model employs multiple filter stages in series, with each stage removing specific contaminants. For example, a pre-filter may remove large particles, followed by a carbon filter for removing dissolved organics, and finally a membrane filter for fine particle removal.

- Advantages: Enhanced efficiency for a wider range of contaminants, can be tailored to specific water quality needs.

- Limitations: More complex design, higher costs compared to single-stage systems.

2.3 Cross-Flow Filtration:

- Description: This model uses a membrane filter where the feed water flows tangentially across the membrane surface. This design minimizes membrane fouling and reduces pressure drop.

- Advantages: High efficiency, low fouling rate, suitable for treating high-volume water streams.

- Limitations: Requires specialized equipment and operating conditions.

2.4 Dead-End Filtration:

- Description: This model uses a membrane filter where the feed water flows directly through the membrane, with the concentrated contaminants accumulating on the membrane surface.

- Advantages: Simple design, relatively low cost.

- Limitations: Susceptible to membrane fouling, requires frequent backwashing or filter replacements.

2.5 Pressure Leaf Filters:

- Description: This model uses multiple filter leaves with filter cloths mounted in a pressurized vessel. This design allows for large filter surface area and efficient filtration.

- Advantages: High throughput, easily cleaned and regenerated, suitable for industrial applications.

- Limitations: Complex design, can be expensive to operate.

2.6 Other Models:

- Rotary Drum Filters: These models use a rotating drum with a filter cloth to filter water.

- Disc Filters: These models utilize a stack of discs with filter cloths to provide a large filtration area.

Choosing the right pressure filtration model depends on factors like the type and concentration of contaminants, the desired flow rate, operational costs, and the specific water treatment needs.

Chapter 3: Software for Pressure Filtration Systems

Software plays a crucial role in optimizing pressure filtration systems, ensuring efficient operation, monitoring performance, and reducing costs. Here's a look at how software supports pressure filtration:

3.1 Process Control and Automation:

- Functionality: Software controls the operation of pumps, valves, and other equipment in the filtration system, ensuring optimal flow rates, pressure settings, and backwashing cycles.

- Benefits: Improved efficiency, reduced manual intervention, minimized downtime, and optimized performance.

3.2 Data Logging and Monitoring:

- Functionality: Software collects data on flow rates, pressure drops, filter performance indicators, and other key parameters. This data is stored for analysis and trending.

- Benefits: Real-time monitoring of system health, early detection of issues, preventive maintenance scheduling, and identification of performance bottlenecks.

3.3 Filter Life Management:

- Functionality: Software tracks filter usage, determines filter life based on pressure drop or other performance indicators, and schedules filter replacements or backwashing cycles.

- Benefits: Optimized filter life, reduced waste, minimized downtime, and lower operational costs.

3.4 Optimization and Modeling:

- Functionality: Software uses simulation models and optimization algorithms to identify areas for improvement, optimize process parameters, and evaluate different filter media or system configurations.

- Benefits: Enhanced efficiency, reduced energy consumption, minimized waste generation, and improved cost effectiveness.

3.5 Reporting and Documentation:

- Functionality: Software generates comprehensive reports on system performance, filter usage, maintenance records, and other relevant data.

- Benefits: Improved accountability, regulatory compliance, easier data analysis, and informed decision-making.

3.6 Software Solutions:

Various software solutions cater to pressure filtration systems, ranging from specialized process control platforms to comprehensive water treatment management systems. Choosing the right software depends on the size and complexity of the system, the specific functionality required, and the budget constraints.

Chapter 4: Best Practices for Pressure Filtration Systems

Optimizing performance, minimizing downtime, and ensuring efficient operation of pressure filtration systems requires adherence to best practices. Here's a guide to ensuring optimal performance:

4.1 Pre-Treatment:

- Importance: Pre-treatment is crucial for removing large particles and other contaminants that can foul the filter media, reducing efficiency and increasing pressure drop.

- Methods: Pre-treatment can involve using screens, grit chambers, flocculation, or other methods to remove coarse solids and improve the quality of feed water.

4.2 Filter Selection and Sizing:

- Considerations: The type and size of filter media, the required flow rate, the desired contaminant removal efficiency, and the available space should all be considered when selecting and sizing the filter.

- Matching Needs: Choose filter media with the appropriate pore size for the target contaminants. Ensure the filter has sufficient capacity to handle the desired flow rate without excessive pressure drop.

4.3 Operation and Maintenance:

- Regular Monitoring: Regularly monitor pressure drop, flow rate, and other performance indicators to detect any changes in filter efficiency.

- Scheduled Backwashing: Perform backwashing or cleaning cycles as needed to remove accumulated solids and regenerate the filter medium.

- Filter Replacements: Replace filter cartridges or media at the recommended intervals to ensure ongoing efficiency and prevent contamination.

4.4 Process Optimization:

- Data Analysis: Analyze data on flow rate, pressure drop, and filter performance to identify areas for improvement.

- Parameter Adjustments: Optimize operating parameters like flow rate, pressure, and backwashing cycles to enhance efficiency and minimize downtime.

4.5 Safety Practices:

- Pressure Relief Valves: Install pressure relief valves to prevent overpressure and ensure the safety of the system.

- Proper Training: Train operators on safe operating procedures, emergency response, and maintenance practices.

4.6 Regulatory Compliance:

- Discharge Standards: Ensure the system meets all relevant regulations and discharge standards for treated water.

- Documentation: Maintain proper records of filter performance, maintenance activities, and other relevant information.

Adherence to these best practices will contribute to the longevity, efficiency, and safety of pressure filtration systems, ensuring reliable and effective water treatment.

Chapter 5: Case Studies of Pressure Filtration Applications

Pressure filtration plays a vital role in a wide range of applications. Here are some case studies showcasing the successful implementation of pressure filtration:

5.1 Municipal Water Treatment:

- Case: A city uses a multi-stage filtration system involving sand filtration, carbon filtration, and membrane filtration to treat its drinking water source.

- Challenge: The raw water source had high turbidity, dissolved organic compounds, and microbial contamination.

- Solution: The multi-stage filtration system effectively removed these contaminants, producing safe and potable water for the city.

5.2 Industrial Wastewater Treatment:

- Case: A manufacturing plant uses pressure filtration to treat wastewater before discharging it to a local river.

- Challenge: The wastewater contained heavy metals, suspended solids, and other pollutants.

- Solution: A combination of membrane filtration and activated carbon filtration effectively removed contaminants, ensuring compliance with discharge limits.

5.3 Food and Beverage Processing:

- Case: A food processing company uses pressure filtration to clarify and purify fruit juices.

- Challenge: The juice contained suspended pulp and other particles that affected clarity and taste.

- Solution: Cartridge filtration with specialized filter media efficiently removed particles, resulting in crystal-clear and high-quality juice.

5.4 Pharmaceutical Manufacturing:

- Case: A pharmaceutical company uses pressure filtration to produce high-purity water for drug manufacturing.

- Challenge: The water needs to be free from all contaminants to ensure the safety and efficacy of drugs.

- Solution: A combination of reverse osmosis and ultraviolet disinfection effectively removes all contaminants, producing pharmaceutical-grade water.

5.5 Swimming Pool and Spa Water Treatment:

- Case: A public swimming pool uses pressure filtration to maintain clean and hygienic water conditions.

- Challenge: Swimming pool water can accumulate dirt, debris, and microbial contamination.

- Solution: Sand filtration removes suspended particles, and chlorine disinfection ensures a healthy swimming environment.

These case studies demonstrate the versatility and effectiveness of pressure filtration in addressing various water treatment challenges across diverse industries.

- absolute pressure Pression Absolue : Un Concept…

- critical pressure Pression Critique : Un Concep…

- atmospheric pressure La pression atmosphérique : u…

- back pressure Contre-Pression : Une Force C…

- constant-rate filtration Filtration à débit constant :…

- crossflow filtration Filtration tangentielle : Un …

- declining-rate filtration Filtration à Débit Décroissan…

- depth filtration Filtration en profondeur : Un…

- direct filtration Filtration Directe : Une Appr…

- filtration rate Taux de filtration : un indic…

- granular media filtration Filtration sur Milieux Granul…

- hyperfiltration Hyperfiltration : La puissanc…

- barometric pressure Pression barométrique : Un hé…

- infiltration Infiltration : Une Menace Sil…

- cake filtration Filtration sur gâteau : Un ou…

- exfiltration Exfiltration : Fuites silenci…

- inflow/infiltration (I/I) Comprendre les Infiltrations …

- groundwater infiltration (GWI) Infiltration des eaux souterr…

- hydrostatic pressure Pression hydrostatique : Le h…

- infiltration gallery Galeries d'infiltration : une…

- Milliéquivalents par litre (meq/L) Comprendre les mill… Surveillance de la qualité de l'eau

- Demande Théorique en Oxygène (DTO) La Demande Théoriqu… Traitement des eaux usées

- L'équivalent en carbonate de calcium (mg/L en CaCO3) L'équivalent en car… Surveillance de la qualité de l'eau

- Solides Suspendus Volatils (VSS) Comprendre les Soli… Traitement des eaux usées

- MAF MAF : Un Géant dans… Gestion durable de l'eau

Comments