Thread and coupling

Buttress

| Outside dia. Regular | 1.66 inches (42,16mm) |

| Outside dia. Special Clearance | – inches (–mm) |

Extreme-lines

| Drift diameter | – inches (–mm) |

| Outside diameter | – inches (–mm) |

| Size Designation | 1.05 : Inches |

| Outside diameter | 1.05 Inches (26,7 mm) |

| Grade | H40 |

| Wall thickness | 0.154 inches (3,91mm) |

| Pipe Carateristics | |

| Weight | 9.5 lb/ft (14,2kg/m) |

| Inside diameter | 0.742 inches (18,84mm) |

| Drift diameter | 3.965 inches (100,71mm) |

| Outside dia. Regular | 1.66 inches (42,16mm) |

| Outside dia. Special Clearance | – inches (–mm) |

| Drift diameter | – inches (–mm) |

| Outside diameter | – inches (–mm) |

| STD | 3,0 ksi |

| Alt | 4,0 ksi |

| STD | 3,0 ksi |

| Alt | 4,0 ksi |

Court | |

| STD | 3,0 ksi |

| Alt | 4,0 ksi |

long | |

| STD | – ksi |

| Alt | – ksi |

Regular | |

| STD | – ksi |

| Alt | – ksi |

Special Clearance | |

| STD | – ksi |

| Alt | – ksi |

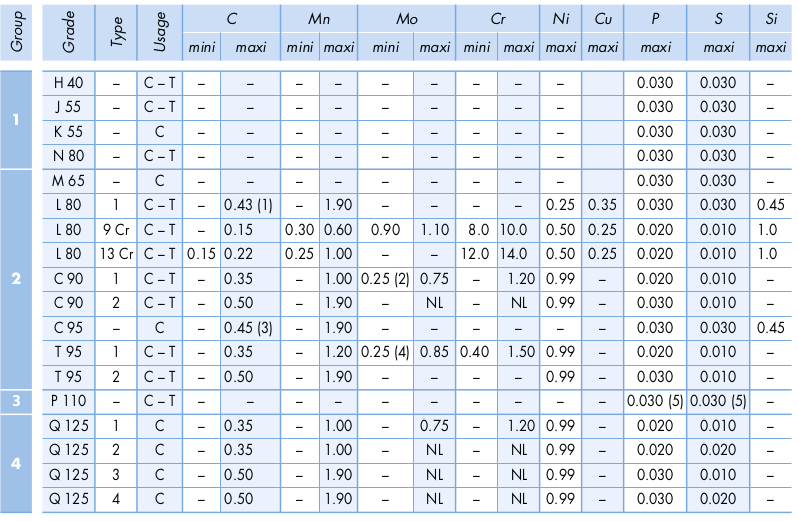

NL : no limit

C : casing

T: tubing

The carbon content for L 80 may be increased to 0.50 % maxi if the product is oil quenched.

No minimum tolerance if the wall thickness is less than 0.700 inches for C 90 grade.

The carbon content for C 95 may be increased to 0.55 % maxi if the product is oil quenched.

The molybdenum content for grade T 95–Type 1 may be decreased to 0.15 % minimum if the wall thickness is less than 0.700 inches.

The phosphorous is 0.020 % maximum and the sulfur is 0.010 % maximum for EW (electric weld, resistance or induction, without the addition of filler metal) grade P 110.

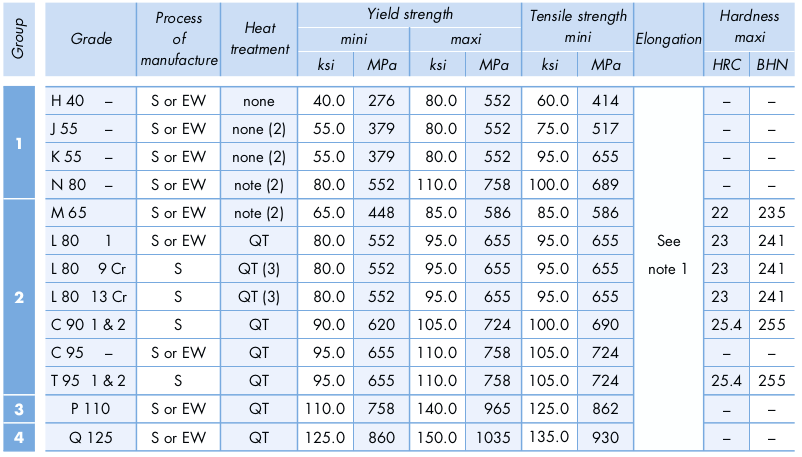

S = seamless

EW = electric weld (resistance or induction) without the addition of filler metal.

QT = quenched and tempered

\(e = 625,000 * { A^{0.2}\over U^{0.9}}\)

where

e = minimum elongation in 2 in. (50.8 mm) in percent to nearest 1/2 percent.

A = cross-sectional area of the tensile test specimen in sq. in.

U = specified minimum ultimate tensile strength in ksi.

N : normalized

T : tempered

Q : quenched

API ROUND THREAD

The pipe is threaded at both ends to have a thread pin the pipes are joined together by means of a coupling. To API specifications, short or long threads with corresponding couplings are available. Long thread casing can transmit higher axial loads than short thread casing.

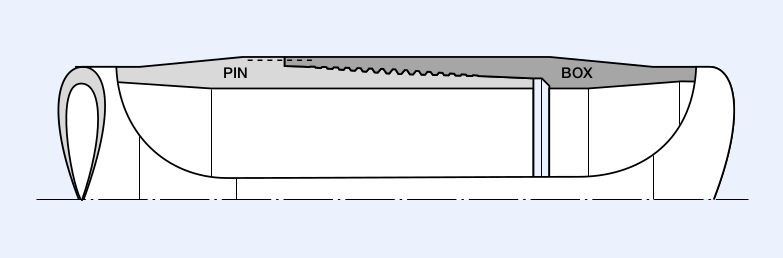

API EXTREME-LINE

Pipes completely differ from the 2 previous types. Endsof pipe are slightly upset where box and pin threads are. In addition, the bottom of the box thread is provi- ded with a machined area where the threaded pin will be pressed during make-up. The thread profile is trapezoidal.

API BUTTRESS

Theconnectingsystemisidenticaltoroundthread.Ins- tead of the «round thread», there is a «buttress» type threadwhichallowsthe transmission of veryhigh axialloads.

COUPLING JOINT

Threaded and coupled API tubing is externally threa- dedonbothendsofanonupset orupset pipe. Single lengthsarejoinedbyaninternallythreadedcoupling. CouplingO.D. canbe«regular» or «special» clea- rance (reduced O.D.). Tubingthread is API round

Nota :special bevel couplings can be furnished for non-upset and upset tubing, as specified on purchase

INTEGRAL JOINT

IntegraljointAPItubingisexternallythreadedoninter- nal upset pipeendandinternally threadedonexternal upset pipe end.

Note1

GRADEMARKING

H40 | H |

J55 | J |

K55 | K |

M 65 | M |

N80 | N |

P110 | P |

L80type1 | L |

L80type9 Cr | L9 |

L80type13Cr | L13 |

C90type1 | C90– 1 |

C90type2 | C90– 2 |

C95 | C95 |

T95type1 | T1 |

T95type2 | T2 |

Q125type1 | Q1 |

Q125type2 | Q2 |

Q125type3 | Q3 |

Q125type4 | Q4 |

Note2

PROCESS O MANUFACTURE

seamless:S

electric welded :E

Note3

TESTPRESSURE

StandardtestpressureST

Alternate testpressureAT

Agreedonpressuregreater thanstandard testpressureHP

Test pressureis3000psiandthestandardtestpressureisgreaterthan3000psi.3K

Note4 TYPEOF THREAD

casing Short round threadLong round thread Buttressthread Extremeline | STCLCBC XC |

tubing Nonupset ExternalupsetIntegraljoint | NU EUIJ |

Note 5

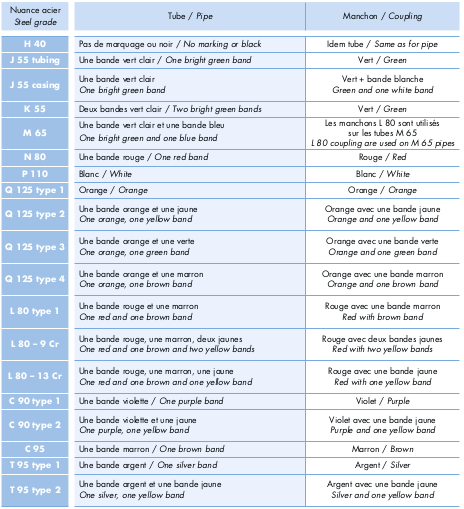

COLOR IDENTIFICATION