Data Management & Analytics

Pareto Diagram

Unlocking Efficiency in Oil & Gas: The Power of the Pareto Diagram

The oil and gas industry is inherently complex, characterized by high stakes, tight deadlines, and constant pressure to optimize efficiency. One crucial tool in this quest for optimization is the Pareto Diagram, a powerful visual representation that helps identify and prioritize the most impactful causes behind various operational challenges.

The Pareto Principle in Action:

The Pareto Diagram is based on the Pareto Principle, also known as the "80/20 rule," which states that 80% of effects come from 20% of causes. In the context of oil and gas, this translates to a few key factors driving the majority of issues, be it downtime, production losses, safety incidents, or environmental concerns.

Visualizing the Data:

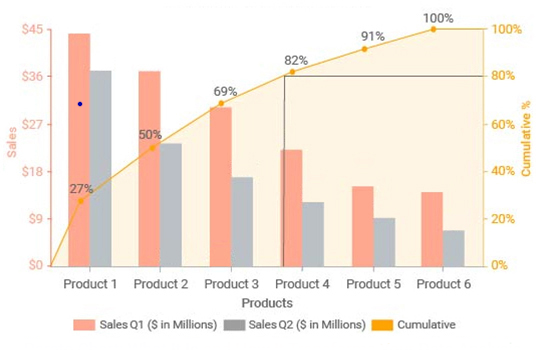

A Pareto Diagram combines two key elements:

- Histogram: A bar chart that visually represents the frequency of occurrence of each cause. The tallest bars represent the most frequent causes, signifying their significant impact.

- Cumulative Frequency Line: A line plot that tracks the percentage of total occurrences accounted for by each cause as you move from left to right. This helps quickly identify the "vital few" causes responsible for the majority of issues.

Applications in Oil & Gas:

The Pareto Diagram finds a wide range of applications within the oil and gas sector, including:

- Production Optimization: Identifying the main causes of downtime in drilling, production, or processing operations, allowing for targeted improvement efforts.

- Safety Improvement: Pinpointing the most frequent contributing factors to accidents and near-misses, enabling proactive measures to minimize risks.

- Environmental Management: Analyzing the sources of pollution or waste generation, guiding targeted interventions for environmental protection.

- Quality Control: Identifying the key factors leading to product defects, helping improve overall product quality and reduce rework.

Benefits of Using a Pareto Diagram:

- Prioritization: Helps focus on the most significant factors driving issues, allowing for efficient resource allocation.

- Data-driven Decision Making: Provides a clear and concise visual representation of the data, enabling informed decision-making.

- Improved Communication: Effectively communicates complex data to stakeholders, promoting understanding and buy-in for improvement initiatives.

- Continuous Improvement: Allows for ongoing monitoring of progress and adjustments to optimization strategies.

Conclusion:

The Pareto Diagram is a valuable tool for oil and gas companies seeking to improve performance, enhance safety, and minimize environmental impact. By understanding the vital few causes behind operational challenges, businesses can prioritize their efforts and achieve significant improvements in efficiency and effectiveness. The Pareto Diagram empowers data-driven decision-making, driving the industry toward a more sustainable and profitable future.

Test Your Knowledge

Quiz: Unlocking Efficiency in Oil & Gas: The Power of the Pareto Diagram

Instructions: Choose the best answer for each question.

1. What is the Pareto Principle, also known as the "80/20 rule"?

a) 80% of the work is done by 20% of the team. b) 80% of the effects come from 20% of the causes. c) 80% of the profits are generated by 20% of the products. d) 80% of the resources are allocated to 20% of the projects.

Answer

b) 80% of the effects come from 20% of the causes.

2. What are the two key elements of a Pareto Diagram?

a) Bar chart and pie chart b) Histogram and line plot c) Scatter plot and line graph d) Flowchart and timeline

Answer

b) Histogram and line plot

3. How does a Pareto Diagram help in Production Optimization?

a) By identifying the most frequent causes of production delays. b) By visualizing the flow of production processes. c) By tracking the progress of production targets. d) By analyzing the cost of production materials.

Answer

a) By identifying the most frequent causes of production delays.

4. Which of the following is NOT a benefit of using a Pareto Diagram?

a) Prioritization of improvement efforts b) Improved communication among stakeholders c) Elimination of all operational challenges d) Data-driven decision making

Answer

c) Elimination of all operational challenges

5. What is the main purpose of the cumulative frequency line in a Pareto Diagram?

a) To show the total number of occurrences. b) To identify the most frequent causes. c) To highlight the "vital few" causes responsible for the majority of issues. d) To compare the frequency of different causes.

Answer

c) To highlight the "vital few" causes responsible for the majority of issues.

Exercise: Applying the Pareto Diagram

Task: Imagine you are working in an oil and gas company, and you've gathered data on the main causes of downtime in your drilling operations. The data is as follows:

| Cause | Frequency | |---|---| | Equipment failure | 20 | | Maintenance delays | 15 | | Weather interruptions | 10 | | Human error | 8 | | Supply chain issues | 7 | | Other | 5 |

Instructions:

- Construct a Pareto Diagram using the given data.

- Identify the "vital few" causes responsible for the majority of downtime.

- Briefly describe how you would use this information to improve drilling efficiency.

Exercice Correction

1. **Constructing the Pareto Diagram:** - Draw a histogram with the causes on the x-axis and frequency on the y-axis. - Label the bars with the frequency of each cause. - Draw a cumulative frequency line, starting at 0% and adding the percentage of occurrences for each cause as you move from left to right. 2. **Identifying the vital few:** - Equipment failure (20) and Maintenance delays (15) account for the largest portion of downtime, making them the "vital few". 3. **Improving Drilling Efficiency:** - **Focus on Equipment Failure:** Invest in preventive maintenance, implement rigorous equipment inspection procedures, and explore upgrades to more reliable equipment. - **Address Maintenance Delays:** Streamline maintenance processes, improve parts availability, and possibly consider outsourcing some maintenance tasks. - The remaining causes should also be addressed, but with less priority than the "vital few".

Books

- The Pareto Principle: How to Achieve Extraordinary Results by Focusing on the Vital Few by Richard Koch: This book delves into the principles behind the Pareto Principle and offers practical strategies for applying it across various domains, including business.

- Lean Six Sigma: A Practical Guide for Managers by David A. Westcott: This book introduces the Lean Six Sigma methodology and covers tools such as the Pareto Diagram for improving efficiency and reducing waste.

- Six Sigma for Dummies by Michael George: This book offers a comprehensive guide to Six Sigma, including how to use Pareto Diagrams for process improvement and quality control.

Articles

- "Pareto Analysis: A Powerful Tool for Process Improvement" by ASQ (American Society for Quality): This article provides a concise overview of the Pareto Diagram, its benefits, and steps for creating it.

- "The Power of the Pareto Diagram" by Quality Digest: This article explores the application of Pareto Diagrams in various industries, including manufacturing, healthcare, and services.

- "Using Pareto Charts to Analyze Safety Data" by Occupational Safety and Health Administration (OSHA): This article demonstrates how to use Pareto Diagrams to analyze safety data and identify key contributing factors to accidents.

Online Resources

- "Pareto Chart" by Wikipedia: Provides a detailed definition, history, and applications of Pareto Diagrams with visual examples.

- "Pareto Chart" by QualityTools.com: This website offers a step-by-step guide on how to create a Pareto Diagram and interpret the results.

- "Pareto Chart Templates" by Microsoft Office: Download pre-designed templates for creating Pareto Diagrams in Excel, PowerPoint, and Word.

Search Tips

- "Pareto Diagram Oil & Gas": Search for articles and resources specifically related to the use of Pareto Diagrams in the oil and gas sector.

- "Pareto Diagram Case Study Oil & Gas": Look for case studies showcasing real-world applications of Pareto Diagrams in improving oil and gas operations.

- "Pareto Diagram Template Excel": Find free Excel templates for creating Pareto Diagrams to analyze your own data.

Techniques

Unlocking Efficiency in Oil & Gas: The Power of the Pareto Diagram

Chapter 1: Techniques for Creating a Pareto Diagram

The creation of a Pareto Diagram involves several key steps to ensure accurate and insightful results. These steps translate raw data into a powerful visual representation that facilitates decision-making.

1. Data Collection: Begin by identifying the problem you want to analyze. This could be anything from equipment downtime to safety incidents. Then, systematically collect relevant data over a defined period. Ensure data accuracy and consistency across the collection process. Examples of data to collect in the Oil & Gas sector might include:

- Downtime events: Type of equipment failure, duration of downtime, cause of failure.

- Safety incidents: Type of incident, location, contributing factors.

- Production losses: Reason for loss, volume of loss, time of occurrence.

2. Data Categorization: Organize the collected data into meaningful categories. These categories should represent the different causes or factors contributing to the problem. Consolidation of similar causes into broader categories may be necessary for clarity. For instance, multiple types of pump failures could be grouped under "Pump Malfunctions."

3. Frequency Counting: Count the number of occurrences for each category. This provides the basis for the histogram component of the Pareto Diagram.

4. Ranking and Sorting: Sort the categories from the most frequent to the least frequent. This is crucial for highlighting the "vital few".

5. Calculation of Cumulative Frequency: Calculate the cumulative percentage of occurrences for each category. Start with the most frequent category and add the percentage of each subsequent category.

6. Diagram Construction: Create the diagram using the following:

- Histogram: Represent the frequency of each category using bars. The height of each bar should be proportional to its frequency.

- Cumulative Frequency Line: Plot the cumulative percentage on a separate scale, connecting the points to create a line graph. This line visualizes the cumulative impact of each category.

7. Chart Labeling and Titling: Clearly label the axes (frequency and cumulative percentage), categories, and provide a descriptive title indicating the problem being analyzed and the time period.

Chapter 2: Models and Interpretations of Pareto Diagrams

While the basic Pareto Diagram is a simple yet powerful tool, understanding its underlying model and interpretations is essential for effective utilization.

The Pareto Diagram relies on the Pareto Principle (80/20 rule), suggesting that approximately 80% of effects stem from 20% of causes. However, this ratio is not always exactly 80/20; it's a guideline rather than a strict rule. The diagram visually reveals the extent to which this principle holds for a specific problem.

Interpretations:

- Identification of Vital Few: The tallest bars and the steepest initial rise of the cumulative frequency line identify the "vital few" causes contributing most significantly to the problem. Focusing improvement efforts on these areas yields the greatest impact.

- Prioritization: The diagram clearly prioritizes causes, enabling efficient allocation of resources for corrective actions.

- Impact Assessment: The cumulative frequency line shows the cumulative impact of addressing causes sequentially. This helps determine the effectiveness of addressing specific causes.

- Limitations: The Pareto Diagram might not capture complex interactions between different causes or indirect effects. It relies on the accuracy and completeness of collected data. It's crucial to consider contextual factors during analysis.

Different models of Pareto analysis exist, for example using weighted values for each category if the impact of each category isn't just about frequency but also severity. This adds complexity but can provide a more nuanced understanding.

Chapter 3: Software for Pareto Diagram Creation

Several software tools facilitate the creation and analysis of Pareto Diagrams, simplifying the process and enhancing accuracy.

Spreadsheet Software (Excel, Google Sheets): These are readily accessible and provide built-in charting capabilities. While requiring manual data input and calculations, they offer flexibility and are sufficient for simpler analyses.

Statistical Software (Minitab, SPSS, R): These offer advanced statistical functions, including automated Pareto Diagram generation and more sophisticated analyses, particularly useful for large datasets or complex scenarios.

Business Intelligence (BI) Tools (Tableau, Power BI): BI tools allow for interactive visualization and data exploration, facilitating in-depth analysis and dynamic updates of the Pareto Diagram as new data becomes available. They are particularly valuable for organizations with extensive data repositories.

Specialized Quality Management Software: Software specifically designed for quality management often includes Pareto Diagram functionality within a broader suite of tools for process improvement.

The choice of software depends on the complexity of the analysis, data volume, technical expertise, and available resources.

Chapter 4: Best Practices for Utilizing Pareto Diagrams in Oil & Gas

Effective utilization of Pareto Diagrams in the Oil & Gas sector requires adherence to certain best practices to maximize their value.

- Define Clear Objectives: Clearly state the problem or area for improvement before data collection. This ensures that data gathering is focused and relevant.

- Accurate Data Collection: Utilize robust data collection methods, ensuring accuracy, consistency, and completeness. Regular data validation is crucial.

- Appropriate Time Frame: Select a time frame that is long enough to capture significant trends, yet short enough to maintain relevance.

- Data Granularity: Balance detailed data with manageable complexity. Too much detail can obscure the key factors.

- Contextual Awareness: Interpret the diagram within the overall operational context. External factors might influence the results.

- Actionable Insights: Translate the insights derived from the diagram into concrete improvement actions.

- Continuous Monitoring: Regularly update and review the Pareto Diagram to monitor the effectiveness of implemented actions and identify emerging issues.

- Stakeholder Collaboration: Involve relevant stakeholders in the process to ensure buy-in and effective implementation of improvement measures.

Chapter 5: Case Studies: Pareto Diagrams in Oil & Gas Applications

This chapter will present real-world examples of Pareto Diagram application in the Oil & Gas industry, demonstrating their effectiveness in solving operational challenges and improving efficiency. (Note: Specific case studies require confidential data, which is not available here. However, examples can be described conceptually).

- Case Study 1: Reducing Downtime in Offshore Drilling: A Pareto Diagram analysis of drilling downtime revealed that "equipment failure" accounted for the majority of incidents. Further analysis within this category indicated a specific type of hydraulic system was the primary culprit. Targeted maintenance and upgrades of this system significantly reduced downtime.

- Case Study 2: Improving Safety Performance in Refining: Analyzing safety incidents revealed that "human error" was the most frequent cause. A Pareto Diagram helped prioritize training programs and safety procedures focusing on the specific types of human error identified.

- Case Study 3: Minimizing Environmental Impact of Pipeline Operations: An analysis of pipeline spills identified "corrosion" as the leading cause. The Pareto Diagram guided investment in improved corrosion prevention techniques and inspection methods.

These examples highlight how Pareto Diagrams help visualize complex problems, prioritize solutions, and facilitate data-driven decision-making for continuous improvement in the oil and gas industry. The adaptability and simplicity of this tool allows for its application across diverse operational areas, driving both efficiency and sustainability.

- Arrow Diagram Arrow Diagrams: Visualizing P…

- Arrow Diagram Method ("ADM") Unveiling the Arrow Diagram M…

- Arrow Diagramming Arrow Diagramming: A Simple T…

- Arrow Diagramming Arrow Diagramming: A Visual T…

- Arrow Diagramming Method Unpacking the Arrow: A Guide …

- Dependency Diagram Dependency Diagrams: Mapping …

- Logic Diagram Logic Diagrams: The Blueprint…

- Network Diagram Visualizing the Flow: Underst…

- Network Diagram Network Diagrams: Charting th…

- Network Diagram Network Diagrams in Oil & Gas…

- Precedence Diagram Unraveling the Path: Understa…

- Precedence Diagram Navigating Project Complexity…

- Precedence Diagram Method Arrow The Arrow: A Powerful Symbol …

- Precedence Diagram Method ("PDM") Mapping Your Project's Path: …

- Precedence Diagram Method ("PDM") Unraveling the Logic: Underst…

- Diagramming Diagramming: A Visual Guide t…

- Flow diagram Flow Diagrams: The Blueprint …

- PNID (Piping and Instrument Diagram) Understanding PNID in Oil & G…

- Flow Diagram Flowing Through Information: …

- Pareto Diagram Prioritizing Problems in Oil …

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments