Drilling & Well Completion

Keyseat

Keyseats: A Silent Threat in Drilling & Well Completion

In the world of drilling and well completion, seemingly minor imperfections can have significant consequences. One such imperfection is the keyseat, a telltale sign of a drilling misadventure that can lead to costly downtime and operational challenges.

What is a Keyseat?

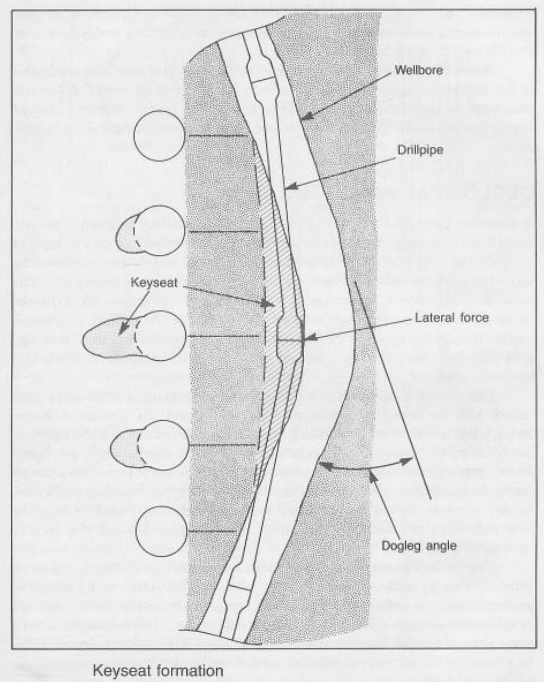

A keyseat is a specific type of wear in the borehole that results in an out-of-round shape, often resembling a keyhole. This occurs when the drill pipe, particularly in crooked or deviated wells, rubs against the side of the hole. The constant friction wears away the rock, creating a groove that widens with time and can extend several feet downhole.

Causes of Keyseats:

- Crooked Holes: When the drill string deviates from the intended trajectory, the drill pipe can scrape against the side of the wellbore, leading to keyseat formation.

- Poor Hole Cleaning: Insufficient circulation of drilling mud can lead to debris accumulating in the wellbore, causing the drill pipe to rub against the side.

- Mechanical Issues: Problems with the drill bit or other equipment can result in vibrations and uneven drilling, increasing the likelihood of keyseats.

Problems Associated with Keyseats:

- Tool Joint Passage: The keyseat’s uneven shape can hinder the passage of tool joints, leading to stuck pipe situations and costly intervention.

- Large Pipe Movement: Larger diameter pipe, used for casing and production tubing, is less flexible than drill pipe. This inflexibility makes it more susceptible to getting stuck in a keyseat, further complicating well operations.

- Increased Friction and Wear: The uneven surface of the keyseat increases friction between the pipe and the wellbore, leading to accelerated wear on the pipe and potentially even catastrophic failure.

Mitigating Keyseat Formation:

- Careful Trajectory Control: Maintaining the intended trajectory of the well using directional drilling techniques can minimize the risk of keyseat formation.

- Efficient Hole Cleaning: Effective circulation of drilling mud removes cuttings from the wellbore, preventing build-up and reducing friction.

- Regular Inspections: Frequent wellbore inspections can detect keyseats early on, allowing for remedial action before they become a major problem.

- Using Keyseat Tools: Specialized tools exist to re-shape the borehole and remove keyseats. However, this is typically a costly and time-consuming process.

Keyseats are a serious challenge in the drilling industry, capable of significantly impacting well operations and profitability. By understanding the causes and consequences of keyseats, operators can implement preventative measures and address the issue early on, minimizing their impact and ensuring smooth well completion.

Test Your Knowledge

Keyseats Quiz

Instructions: Choose the best answer for each question.

1. What is a keyseat?

(a) A type of drill bit used for specific rock formations. (b) A groove in the wellbore caused by the drill pipe rubbing against the side. (c) A specialized tool for cleaning debris from the wellbore. (d) A protective coating applied to drill pipe to reduce friction.

Answer

(b) A groove in the wellbore caused by the drill pipe rubbing against the side.

2. Which of the following is NOT a cause of keyseats?

(a) Crooked holes (b) Insufficient mud circulation (c) Use of a specific type of drilling mud (d) Mechanical issues with the drill bit

Answer

(c) Use of a specific type of drilling mud

3. What is a major problem associated with keyseats?

(a) Reduced drilling speed (b) Difficulty in running casing and tubing (c) Increased risk of wellbore collapse (d) Reduced lifespan of drilling mud

Answer

(b) Difficulty in running casing and tubing

4. Which of the following is a preventative measure to mitigate keyseat formation?

(a) Using a specialized type of drill bit (b) Increasing the drilling fluid density (c) Maintaining a precise well trajectory (d) Injecting chemicals into the wellbore

Answer

(c) Maintaining a precise well trajectory

5. What is a specialized tool used to address keyseats?

(a) Keyseat reamer (b) Keyseat cutter (c) Keyseat scraper (d) All of the above

Answer

(d) All of the above

Keyseats Exercise

Scenario: You are a drilling engineer working on a deviated well. During a routine wellbore inspection, you notice a keyseat starting to form. Explain the potential risks associated with this keyseat and describe three actions you would take to address the issue.

Exercice Correction

The keyseat poses several risks: * **Stuck pipe:** The keyseat's uneven shape could cause the drill pipe or larger casing/tubing to get stuck, leading to costly and time-consuming intervention. * **Increased friction and wear:** The uneven surface creates more friction, accelerating wear on the pipe and potentially leading to a catastrophic failure. * **Difficulty in future operations:** The keyseat can make running casing, tubing, or other downhole equipment difficult and risky. To address the issue, I would: 1. **Adjust the trajectory:** Carefully analyze the wellbore path and adjust the drilling trajectory slightly to reduce contact between the drill pipe and the wellbore wall, preventing further keyseat development. 2. **Optimize mud circulation:** Ensure sufficient mud circulation to effectively remove cuttings and prevent buildup. This will minimize the friction caused by debris and reduce wear on the drill pipe. 3. **Consider keyseat remediation tools:** If the keyseat is already significant, consider utilizing specialized keyseat reamers or cutters to reshape the wellbore and eliminate the groove. While keyseat remediation is a costly and time-consuming process, it may be necessary in some cases to prevent future complications and ensure a successful well completion.

Books

- Petroleum Engineering Handbook: This comprehensive handbook covers various aspects of drilling, including wellbore stability and issues like keyseats. Look for chapters on drilling mechanics, wellbore stability, and directional drilling.

- Drilling Engineering: This book focuses on the technical aspects of drilling operations, including topics related to drillstring dynamics, wellbore geometry, and keyseat formation.

- Well Completion Engineering: This book discusses the procedures and equipment used for well completion, including challenges like keyseats encountered during casing running and tubing installation.

Articles

- "Keyseat Formation: A Silent Threat to Wellbore Stability" by [Author's Name] - This article could delve into the mechanics of keyseat formation, analyze different contributing factors, and discuss mitigation strategies.

- "Case Study: Keyseat Remediation in a Deviated Well" by [Author's Name] - This case study could provide real-world insights into the challenges posed by keyseats and the methods used to resolve them.

- "The Impact of Keyseats on Well Completion Operations" by [Author's Name] - This article could explore the implications of keyseats during casing and tubing running, highlighting potential risks and cost implications.

Online Resources

- SPE (Society of Petroleum Engineers): Explore the SPE website for publications, presentations, and discussions on keyseat formation and mitigation.

- IADC (International Association of Drilling Contractors): Search IADC publications and resources for technical papers and industry best practices regarding keyseat prevention and remediation.

- DrillingInfo: This online platform provides data and analysis on drilling operations, including information on wellbore stability and keyseat occurrences.

- Oil & Gas Journal: This industry journal frequently publishes articles on drilling and well completion, including topics related to keyseats.

Search Tips

- "Keyseat formation drilling"

- "Keyseat remediation well completion"

- "Drilling wellbore stability keyseats"

- "Directional drilling keyseat prevention"

- "Case study keyseat stuck pipe"

Techniques

Chapter 1: Techniques for Identifying and Analyzing Keyseats

This chapter delves into the various techniques employed to identify and analyze keyseats in drilling and well completion operations.

1.1. Visual Inspection:

- Downhole Cameras: Utilizing downhole cameras, operators can visually assess the wellbore for keyseats. This method provides direct visual confirmation of the keyseat's size, shape, and location.

- Wireline Logging Tools: Specialized wireline logging tools can be used to measure the wellbore's diameter and identify deviations from a circular profile, indicating the presence of keyseats.

1.2. Measurement and Quantification:

- Caliper Logs: Caliper logs measure the wellbore diameter at various depths, providing a detailed profile of the hole. This data helps identify keyseats and assess their severity.

- Borehole Imaging Tools: These tools capture high-resolution images of the wellbore, providing valuable insights into keyseat morphology and extent.

1.3. Keyseat Classification:

- Keyseat Severity: Keyseats are often classified based on their severity, with categories like "minor," "moderate," and "severe" reflecting the depth, width, and overall impact of the keyseat.

- Keyseat Orientation: The orientation of the keyseat relative to the wellbore can be analyzed to understand the potential impact on tool joint passage and pipe movement.

1.4. Challenges and Limitations:

- Limited Access: Accessing the wellbore, especially in deviated or horizontal wells, can be challenging. This may restrict the use of certain inspection techniques.

- Data Interpretation: Interpreting data from various logging tools requires expertise and experience to accurately identify and quantify keyseats.

1.5. Conclusion:

Understanding and utilizing the right techniques for identifying and analyzing keyseats is crucial in mitigating their negative impact on well operations. Early detection and proper assessment enable operators to make informed decisions and take appropriate actions to address keyseat problems.

Chapter 2: Models for Keyseat Prediction and Prevention

This chapter explores the use of predictive models and simulation tools to understand keyseat formation and develop strategies for prevention.

2.1. Empirical Models:

- Drillstring Dynamics: Models that analyze drillstring dynamics and the forces acting on the pipe during drilling can be used to predict the likelihood of keyseat formation.

- Drilling Fluid Rheology: Models that consider the rheological properties of drilling fluids can help assess the effectiveness of hole cleaning and predict keyseat formation based on fluid flow patterns.

2.2. Numerical Simulation:

- Finite Element Analysis (FEA): FEA software can be used to simulate the interaction between the drillstring and the wellbore, accounting for complex geological formations, drilling parameters, and fluid flow.

- Computational Fluid Dynamics (CFD): CFD models can simulate the flow of drilling fluids and cuttings, providing insights into hole cleaning efficiency and the risk of keyseat formation.

2.3. Keyseat Prediction Strategies:

- Trajectory Optimization: By optimizing the wellbore trajectory, operators can minimize the contact between the drillstring and the wellbore, reducing the risk of keyseat formation.

- Drilling Fluid Optimization: Adjusting the rheology and properties of drilling fluids can enhance hole cleaning and reduce the likelihood of keyseat formation.

2.4. Challenges and Limitations:

- Model Complexity: Accurately modeling the complex interactions within the wellbore requires comprehensive data and advanced computational power.

- Data Availability: Limited data availability and uncertainties in geological models can impact the accuracy of predictions.

2.5. Conclusion:

Predictive models and simulation tools play a critical role in proactive keyseat management. By leveraging these tools, operators can optimize drilling operations, reduce the risk of keyseat formation, and minimize the impact of these issues on well completion.

Chapter 3: Software for Keyseat Analysis and Remediation

This chapter focuses on the software tools and applications specifically designed for keyseat analysis and remediation.

3.1. Keyseat Detection and Measurement Software:

- Wellbore Imaging Software: Specialized software applications can analyze borehole images captured by imaging tools, automatically identifying keyseats and providing detailed measurements of their dimensions.

- Caliper Log Analysis Software: Software tools that analyze caliper log data can automatically identify keyseats and their location, providing a comprehensive wellbore profile for decision making.

3.2. Keyseat Remediation Planning Software:

- Wellbore Simulation Software: Software applications that simulate the interaction between the drillstring and the wellbore can be used to plan remedial actions for keyseats, such as optimizing pipe movement and minimizing the risk of stuck pipe.

- Keyseat Milling Tool Design Software: Software tools for designing keyseat milling tools allow engineers to create customized solutions for removing keyseats based on their size and shape.

3.3. Keyseat Monitoring and Management Software:

- Wellbore Data Management Software: Integrated software platforms can store and manage all relevant wellbore data, including keyseat measurements, enabling operators to track the evolution of keyseats and monitor their potential impact on well operations.

3.4. Challenges and Considerations:

- Software Compatibility: Ensuring compatibility between different software tools and data formats can be challenging, requiring careful consideration of software integration.

- Software Training and Expertise: Effective use of these specialized software tools requires proper training and expertise to interpret data and make informed decisions.

3.5. Conclusion:

Software tools are essential for efficient keyseat analysis and remediation. By utilizing the right software applications, operators can streamline data analysis, optimize keyseat management strategies, and improve decision-making for well completion operations.

Chapter 4: Best Practices for Keyseat Management

This chapter outlines a set of best practices for mitigating keyseat formation and managing their impact on drilling and well completion.

4.1. Proactive Measures:

- Minimize Wellbore Deviation: Employing advanced directional drilling techniques and strict trajectory control minimizes the contact between the drillstring and the wellbore, reducing keyseat formation.

- Effective Hole Cleaning: Optimize drilling fluid rheology and flow rates to ensure efficient removal of cuttings from the wellbore, reducing friction and preventing keyseat development.

- Regular Monitoring and Inspections: Conduct frequent wellbore inspections using downhole cameras and logging tools to detect keyseats early on, allowing for timely interventions.

4.2. Remedial Actions:

- Keyseat Milling: Utilize specialized keyseat milling tools to reshape the wellbore and remove keyseats, enabling the passage of casing and production tubing.

- Wellbore Deviation Correction: Employ directional drilling techniques to adjust the wellbore trajectory and reduce the severity of keyseats.

- Pipe Movement Optimization: Use simulations and software tools to optimize pipe movement and minimize the risk of stuck pipe due to keyseats.

4.3. Documentation and Data Management:

- Maintain Detailed Logs: Thoroughly document all keyseat findings, including size, location, and remedial actions taken, providing a comprehensive record for future reference.

- Share Information: Share keyseat data across different departments and projects to ensure consistency in best practices and inform future drilling operations.

4.4. Continuous Improvement:

- Review and Analyze: Regularly review keyseat data and identify areas for improvement in drilling techniques, hole cleaning practices, and wellbore inspections.

- Embrace Innovation: Stay updated on advancements in keyseat detection and remediation technologies, implementing new tools and techniques to enhance keyseat management.

4.5. Conclusion:

By adhering to these best practices, operators can proactively address keyseat issues, minimize their impact on well operations, and ensure efficient and cost-effective well completion.

Chapter 5: Case Studies of Keyseat Challenges and Solutions

This chapter showcases real-world examples of keyseat challenges faced by drilling operators and the solutions implemented to overcome these issues.

5.1. Case Study 1: Keyseat Formation in a Deviated Well:

- Challenge: A keyseat formed in a deviated wellbore, hindering the passage of casing during well completion.

- Solution: Keyseat milling tools were used to reshape the wellbore and allow the casing to be run successfully.

5.2. Case Study 2: Keyseat-Induced Stuck Pipe Incident:

- Challenge: A stuck pipe incident occurred due to a keyseat in a horizontal wellbore, leading to significant downtime and costs.

- Solution: A combination of keyseat milling, wellbore deviation correction, and specialized pipe retrieval techniques were employed to successfully recover the stuck pipe.

5.3. Case Study 3: Keyseat Prevention through Trajectory Optimization:

- Challenge: An operator implemented a wellbore trajectory optimization strategy to minimize keyseat formation in a complex geological formation.

- Solution: By carefully planning the wellbore path, the risk of keyseat formation was significantly reduced, leading to smoother well completion and reduced operational costs.

5.4. Case Study 4: Keyseat Detection and Remediation Using Advanced Software:

- Challenge: A keyseat was detected early on using advanced wellbore imaging software, enabling proactive remediation before it caused significant problems.

- Solution: Keyseat milling was performed immediately, preventing the keyseat from further developing and ensuring smooth well completion.

5.5. Conclusion:

These case studies demonstrate the importance of early keyseat detection, proactive measures, and the application of innovative solutions to address keyseat challenges. By analyzing and sharing real-world experiences, operators can learn from past mistakes and implement effective strategies for managing keyseats in future drilling operations.

- keyseat Understanding Keyseats in…

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments