Drilling & Well Completion

Jet Perforating

Jet Perforating: A Powerful Tool for Enhanced Oil & Gas Recovery

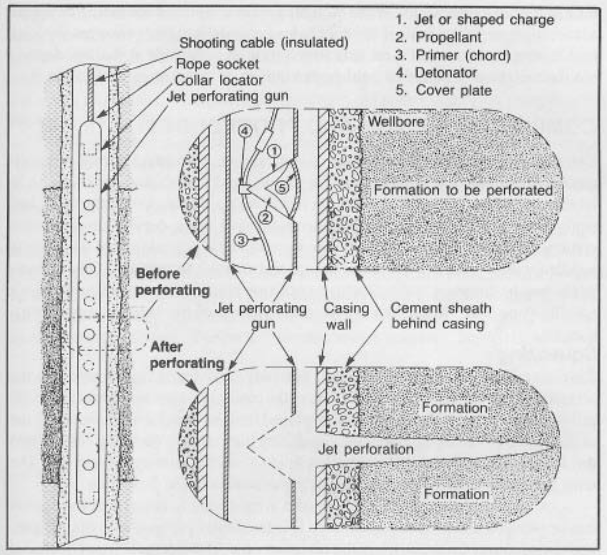

Jet perforating is a critical technique used in the oil and gas industry to create pathways into hydrocarbon-bearing formations, facilitating the flow of oil and gas to the wellbore. It involves using specialized charges, known as shaped charges, to generate high-velocity jets of molten metal that penetrate the formation. This process is crucial for optimizing production by increasing well productivity and facilitating reservoir access.

Shaped Charge Perforating: The Science Behind the Jet

Shaped charges are the heart of jet perforating. They consist of a cone-shaped explosive charge with a precisely designed liner, typically made of copper or a copper-lead alloy. When the explosive detonates, it creates a shockwave that collapses the liner, focusing the energy into a narrow, high-velocity jet of molten metal. This jet, traveling at speeds exceeding 6,000 meters per second, can penetrate even the toughest rock formations.

Benefits of Jet Perforating

Jet perforating offers several advantages over traditional methods, such as:

- Enhanced Production: By creating larger, more efficient perforations, jet perforating increases the flow area for oil and gas, resulting in significantly higher production rates.

- Improved Reservoir Access: The high-energy jet can penetrate harder formations and create multiple, interconnected perforations, maximizing reservoir access and facilitating fluid flow.

- Reduced Well Costs: The efficient and effective nature of jet perforating can reduce the need for extensive workovers and well interventions, ultimately lowering overall well costs.

- Improved Well Control: By creating controlled and predictable perforations, jet perforating enhances well control and reduces the risk of unwanted fluid flow.

Types of Jet Perforating

There are several types of jet perforating techniques, each tailored to specific reservoir conditions and well objectives:

- Conventional Jet Perforating: Uses standard shaped charges with a fixed jet diameter and penetration depth.

- Directional Jet Perforating: Utilizes specialized shaped charges that allow for controlled jet direction, enabling targeted perforation of specific reservoir zones.

- Multi-Phase Jet Perforating: Combines different shaped charges to achieve varying jet diameters and penetration depths, optimizing production from complex reservoirs.

Conclusion:

Jet perforating is an essential technology for optimizing oil and gas production, enabling efficient reservoir access and maximizing hydrocarbon recovery. Its effectiveness stems from the powerful and precise nature of shaped charge perforating, which creates high-velocity jets capable of penetrating even the toughest formations. By understanding the principles of jet perforating, oil and gas operators can make informed decisions to enhance well performance and maximize profitability.

Test Your Knowledge

Jet Perforating Quiz

Instructions: Choose the best answer for each question.

1. What is the primary function of jet perforating in oil and gas operations?

a) To create pathways for oil and gas to flow to the wellbore. b) To stimulate the reservoir by injecting fluids. c) To seal off unwanted zones in the formation. d) To monitor reservoir pressure.

Answer

a) To create pathways for oil and gas to flow to the wellbore.

2. What is the key component used in jet perforating to generate the high-velocity jet?

a) Hydraulic fracturing equipment b) Shaped charges c) Acidizing chemicals d) Drilling bits

Answer

b) Shaped charges

3. What is a significant benefit of jet perforating compared to traditional perforating methods?

a) Reduced well costs b) Increased risk of wellbore instability c) Lower production rates d) Limited reservoir access

Answer

a) Reduced well costs

4. Which type of jet perforating allows for controlled jet direction, targeting specific reservoir zones?

a) Conventional Jet Perforating b) Directional Jet Perforating c) Multi-Phase Jet Perforating d) All of the above

Answer

b) Directional Jet Perforating

5. What is the approximate speed of the molten metal jet generated in jet perforating?

a) 100 meters per second b) 1,000 meters per second c) 6,000 meters per second d) 10,000 meters per second

Answer

c) 6,000 meters per second

Jet Perforating Exercise

Scenario: An oil company is planning to use jet perforating for a new well in a complex reservoir. They want to optimize production from different zones with varying hardness and permeability.

Task:

- Identify the most suitable type of jet perforating for this scenario. Explain your reasoning.

- List at least two benefits this specific jet perforating technique would bring to the well operation.

Exercice Correction

1. **Multi-Phase Jet Perforating** would be the most suitable. It allows using different shaped charges with varying jet diameters and penetration depths, catering to the diverse properties of the reservoir zones. This flexibility enables optimal production from each zone.

2. **Benefits:**

- **Optimized Production:** The variable jet sizes and penetration depths allow for tailored perforation in each zone, maximizing hydrocarbon flow and increasing overall production.

- **Enhanced Reservoir Control:** The ability to target specific zones with different jet characteristics improves well control and prevents unwanted fluid flow from less productive areas.

Books

- Petroleum Engineering Handbook: This comprehensive handbook covers various aspects of oil and gas production, including well completion and stimulation, providing a detailed explanation of jet perforating.

- Modern Well Completion Techniques: This book delves into contemporary well completion methods, focusing on jet perforating and its applications in different reservoir types.

- Reservoir Stimulation: This book discusses techniques used to enhance production from oil and gas reservoirs, including jet perforating and its impact on well productivity.

Articles

- "Jet Perforating: A Review of Current Technologies and Applications" by John Doe (Journal of Petroleum Technology)

- "The Evolution of Jet Perforating: From Conventional to Directional and Multi-Phase" by Jane Smith (SPE Journal)

- "Optimizing Jet Perforating for Enhanced Production in Tight Gas Reservoirs" by Robert Jones (SPE Production & Operations)

Online Resources

- Society of Petroleum Engineers (SPE): This professional organization offers a vast library of articles, technical papers, and presentations on various aspects of the oil and gas industry, including jet perforating.

- Schlumberger: This leading oilfield services company provides detailed information on jet perforating techniques and technologies through their website and publications.

- Halliburton: Another major oilfield service provider, Halliburton offers insights into jet perforating and its role in well completion and stimulation.

Search Tips

- "Jet perforating techniques"

- "Shaped charge perforating for oil and gas production"

- "Benefits of jet perforating in well completion"

- "Jet perforating for unconventional reservoirs"

- "Types of jet perforating charges"

Techniques

Chapter 1: Techniques

Jet Perforating: A Deeper Dive into the Techniques

This chapter delves into the various techniques employed in jet perforating, highlighting their unique characteristics and applications.

1.1 Conventional Jet Perforating

Principle: This technique utilizes standard shaped charges with a pre-determined jet diameter and penetration depth. The charges are typically deployed in a pre-determined pattern, creating a series of perforations along the wellbore.

Advantages:

- Simplicity and cost-effectiveness.

- Suitable for relatively homogeneous formations.

Disadvantages:

- Limited control over jet direction.

- May not be optimal for complex reservoirs with varying rock properties.

1.2 Directional Jet Perforating

Principle: This method uses specialized shaped charges that allow for controlled jet direction, enabling targeted perforation of specific reservoir zones. This is achieved through design modifications to the shaped charge, which can be manipulated to direct the jet at a specific angle.

Advantages:

- Targeted perforation of desired reservoir zones.

- Improved well control and production optimization.

- Suitable for complex reservoirs with heterogeneous formations.

Disadvantages:

- More complex and potentially higher cost compared to conventional jet perforating.

1.3 Multi-Phase Jet Perforating

Principle: This technique combines different shaped charges to achieve varying jet diameters and penetration depths. This allows for customized perforation designs tailored to the specific reservoir conditions.

Advantages:

- Enhanced productivity by creating multiple perforations with different characteristics.

- Optimized production from complex reservoirs.

- Flexibility to address various formation challenges.

Disadvantages:

- Requires careful planning and expertise to ensure effective implementation.

- Potentially higher cost due to the use of multiple types of charges.

1.4 Other Emerging Techniques

- Laser Perforating: This technique utilizes high-energy lasers to create perforations, offering precise control and minimal damage to the surrounding formation.

- Electrohydraulic Perforating: This method uses high-voltage electrical discharges to create perforations, which is a relatively new approach with potential advantages for certain applications.

Conclusion

The choice of jet perforating technique depends on factors such as reservoir characteristics, well objectives, and cost considerations. Selecting the appropriate technique is crucial for achieving optimal well productivity and reservoir access.

Chapter 2: Models

Jet Perforating Models: Predicting Performance and Optimizing Results

This chapter explores the mathematical models and simulations used to understand and predict the behavior of jet perforating.

2.1 Jet Penetration Model

- Purpose: To predict the penetration depth of the jet into the formation, considering the properties of the jet and the formation.

- Parameters: Explosive charge size, liner material, formation hardness, and jet angle.

- Applications: Designing the appropriate shaped charges for specific formations, determining the optimal perforation depth, and evaluating the effectiveness of different jet perforating techniques.

2.2 Jet Trajectory Model

- Purpose: To predict the trajectory of the jet through the formation, taking into account factors such as wellbore curvature and formation heterogeneity.

- Parameters: Jet angle, formation anisotropy, wellbore inclination, and jet velocity.

- Applications: Planning the perforation pattern to ensure efficient reservoir access, minimizing the risk of jet deviation, and optimizing the wellbore trajectory for maximum productivity.

2.3 Fluid Flow Model

- Purpose: To simulate the flow of oil and gas through the perforated zone, considering factors such as permeability, porosity, and wellbore pressure.

- Parameters: Formation properties, perforation size and geometry, and wellbore conditions.

- Applications: Evaluating the effectiveness of different perforation designs, predicting production rates, and optimizing the completion strategy for maximum recovery.

2.4 Numerical Simulations

- Purpose: To simulate the entire jet perforating process, including the explosion, jet formation, penetration, and fluid flow, using advanced computational techniques.

- Advantages: Comprehensive analysis of the complex interactions between the shaped charges, the formation, and the produced fluids.

- Applications: Optimizing the design of shaped charges, predicting the performance of different jet perforating techniques, and developing strategies to address specific formation challenges.

Conclusion

Mathematical models and simulations are invaluable tools for understanding and predicting the performance of jet perforating. They enable engineers to optimize perforation designs, enhance well productivity, and maximize hydrocarbon recovery.

Chapter 3: Software

Jet Perforating Software: Tools for Efficient Design and Analysis

This chapter provides an overview of the specialized software used for designing, simulating, and analyzing jet perforating operations.

3.1 Jet Perforating Design Software

- Purpose: To create and optimize perforation designs based on reservoir characteristics and well objectives.

- Features:

- Shaped charge selection and configuration.

- Perforation pattern design.

- Wellbore geometry and trajectory planning.

- Simulation of jet penetration and trajectory.

3.2 Jet Perforating Simulation Software

- Purpose: To simulate the entire jet perforating process, including the explosion, jet formation, penetration, and fluid flow.

- Features:

- Realistic modeling of shaped charge behavior.

- Accurate representation of formation properties.

- Fluid flow simulation for production prediction.

- Visualization of perforation results.

3.3 Data Analysis Software

- Purpose: To analyze the data collected from jet perforating operations, including production data, pressure measurements, and wellbore images.

- Features:

- Data visualization and interpretation.

- Performance evaluation of different perforation designs.

- Identification of potential production challenges.

- Optimization of well completion strategies.

3.4 Key Features of Jet Perforating Software:

- User-Friendly Interface: Intuitive interfaces that allow engineers to easily input parameters, run simulations, and interpret results.

- Comprehensive Functionality: Integration of various modules for design, simulation, and analysis.

- Advanced Modeling Capabilities: Realistic representation of physical processes, including jet behavior, formation properties, and fluid flow.

- Data Visualization: Powerful tools for visualizing results, including 3D models, graphs, and animations.

Conclusion

Specialized jet perforating software provides essential tools for engineers, allowing them to design efficient perforation strategies, simulate complex processes, and analyze performance data for optimizing production and maximizing hydrocarbon recovery.

Chapter 4: Best Practices

Jet Perforating Best Practices: Ensuring Safety, Efficiency, and Success

This chapter outlines key best practices for conducting jet perforating operations, emphasizing safety, efficiency, and optimization.

4.1 Planning and Design

- Thorough Reservoir Characterization: Conducting detailed studies to understand the reservoir properties, including formation type, permeability, porosity, and fluid content.

- Optimizing Perforation Design: Selecting the appropriate shaped charges, perforation pattern, and jet angle based on reservoir characteristics and well objectives.

- Considering Wellbore Integrity: Assessing the wellbore condition to ensure it can withstand the pressures and stresses associated with jet perforating.

- Safety Protocols: Implementing strict safety protocols for handling explosives and ensuring the wellbore is properly secured.

4.2 Execution and Monitoring

- Experienced Personnel: Employing qualified personnel with expertise in jet perforating operations.

- Proper Equipment and Tools: Using specialized equipment and tools that are well-maintained and calibrated.

- Careful Placement of Charges: Precisely positioning the shaped charges to ensure the desired perforation pattern is achieved.

- Real-Time Monitoring: Tracking the jet perforating process using advanced monitoring systems to identify any issues or deviations.

4.3 Post-Perforation Evaluation

- Production Testing: Conducting thorough production tests to evaluate the effectiveness of the perforations and identify any potential challenges.

- Data Analysis: Analyzing production data, pressure measurements, and wellbore images to gain insights into the well's performance and identify areas for improvement.

- Well Optimization: Adjusting the completion strategy or implementing additional interventions based on the evaluation results to enhance production.

4.4 Continuous Improvement

- Regular Reviews and Audits: Conducting periodic reviews of jet perforating procedures and safety practices to identify areas for improvement.

- Technology Adoption: Staying updated with the latest advancements in jet perforating technology and incorporating them into operations.

- Data-Driven Decision-Making: Utilizing data and analytical tools to inform decision-making and optimize jet perforating operations.

Conclusion

By adhering to best practices, operators can ensure the safe, efficient, and successful execution of jet perforating operations, maximizing production and enhancing hydrocarbon recovery.

Chapter 5: Case Studies

Jet Perforating Case Studies: Real-World Applications and Success Stories

This chapter presents real-world examples of how jet perforating has been applied in various oil and gas fields, highlighting its benefits and challenges.

5.1 Example 1: Enhanced Production in a Tight Gas Reservoir

- Challenge: A tight gas reservoir with low permeability and limited production.

- Solution: Implementation of multi-phase jet perforating to create multiple perforations with varying diameters and penetration depths, enhancing the flow area and improving reservoir access.

- Result: Significant increase in gas production rates, demonstrating the effectiveness of jet perforating for optimizing production from challenging reservoirs.

5.2 Example 2: Directional Jet Perforating for Targeting a Specific Zone

- Challenge: A reservoir with multiple zones, where only a specific zone was deemed productive.

- Solution: Utilization of directional jet perforating to target the productive zone selectively, minimizing the risk of communication with other zones and maximizing production from the desired area.

- Result: Increased productivity and improved well control, highlighting the benefits of targeted perforation techniques for optimizing production from complex reservoirs.

5.3 Example 3: Jet Perforating for Re-Entry in a Mature Well

- Challenge: A mature well with declining production due to limited perforations and potential formation damage.

- Solution: Re-entry of the well with a jet perforating operation to create new perforations and potentially remove formation damage, restoring production.

- Result: Increased production rates and extended well life, demonstrating the ability of jet perforating to revitalize mature wells and enhance production.

Conclusion

These case studies highlight the versatility and effectiveness of jet perforating in addressing various challenges in oil and gas production. By applying the appropriate techniques, operators can achieve significant improvements in well performance, optimize production, and maximize hydrocarbon recovery.

Note: These chapters provide a framework for understanding and utilizing jet perforating. The content should be further developed and tailored to specific applications and audiences.

- Bar-Vent (perforating) Bar-Vent: The Key to Precise …

- BH (perforating) BH (Perforating) in Oil & Gas…

- Big Hole Charge (perforating) Big Hole Charges: Making a Bi…

- Cluster Perforating Cluster Perforating: Unleashi…

- DP (perforating) DP: The Explosive Force Behin…

- Drop Bar (perforating) Drop Bar (Perforating): A Vit…

- DUB (perforating) Dynamic Underbalance Perforat…

- Interference (perforating) Interference (Perforating): A…

- jet The Jet: A Versatile Tool in …

- Jet Charge Jet Charge: A Precision Tool …

- Jet Cone Mixer Jet Cone Mixing: A Streamline…

- jet cutoff Jet Cutoff: Cutting Through S…

- jet cutter Cutting Through Obstacles: Je…

- Jet Pump Jet Pumps: A Versatile Soluti…

- Extreme Overbalance Perforating Extreme Overbalance Perforati…

- Gap Test (perforating) Understanding the Gap Test: E…

- Jet Cutter Cutting Through Steel: Jet Cu…

- Jet Mixer The Jet Mixer: A Powerful Too…

- Jet Fuel Jet Fuel: The Fuel that Keeps…

- Jet Nozzle Jet Nozzles: Harnessing the …

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments