Drilling & Well Completion

Gas Gravity

Gas Gravity: A Key Parameter in Oil & Gas Exploration and Production

In the world of oil and gas, understanding the properties of the substances you're working with is crucial. One important parameter used to characterize natural gas is gas gravity. This seemingly simple concept plays a vital role in various aspects of oil and gas exploration and production, from well testing to pipeline design.

What is Gas Gravity?

Gas gravity is a dimensionless number that represents the ratio of the density of a gas to the density of air at the same temperature and pressure. It essentially tells us how "heavy" a gas is compared to air. This ratio is also equal to the ratio of the molecular weight of the gas to the molecular weight of air (28.97).

Why is Gas Gravity Important?

Gas gravity has significant implications in various aspects of the oil and gas industry:

- Well Testing: During well testing, gas gravity helps determine the composition and quality of the produced gas. It can indicate the presence of heavier hydrocarbons like propane and butane, which have higher gas gravity values.

- Pipeline Design: The density of the gas affects the pressure and flow rates in pipelines. Knowing the gas gravity allows engineers to design pipelines that can safely and efficiently transport the gas.

- Gas Sales: Gas gravity is used to calculate the volume of gas sold based on its weight. This is important for accurate billing and pricing of natural gas.

- Reservoir Characterization: Gas gravity can provide insights into the composition and properties of the reservoir. This information helps in determining the potential productivity of the well.

How is Gas Gravity Measured?

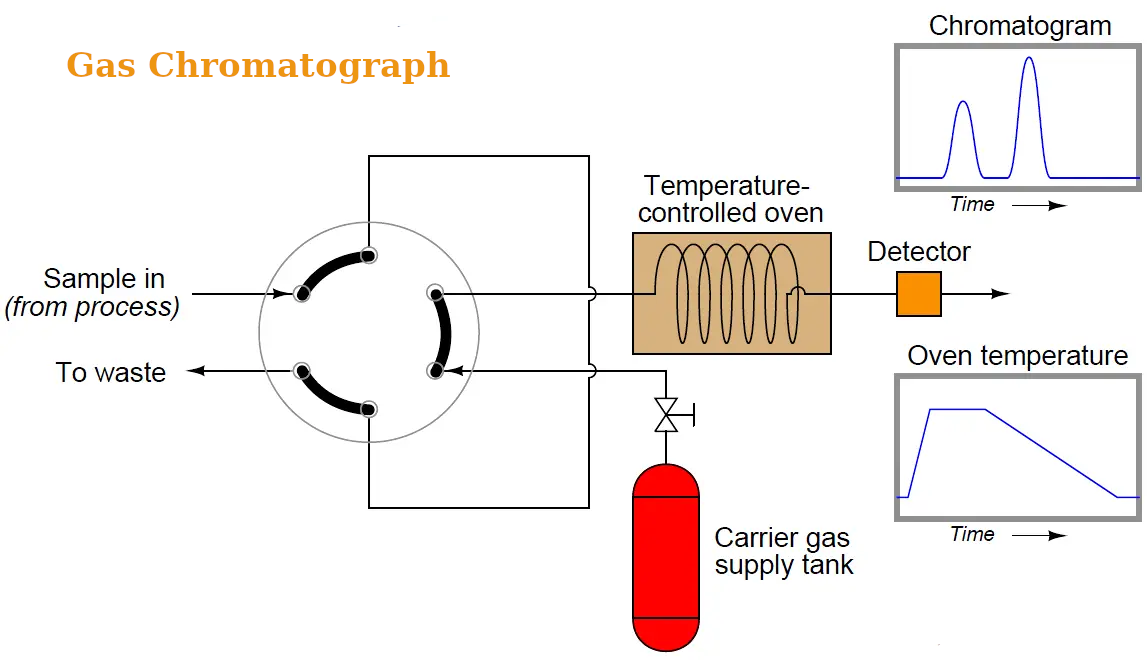

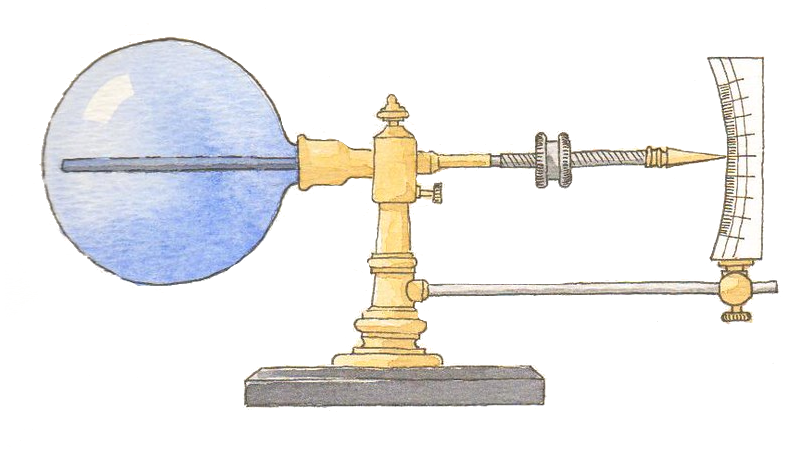

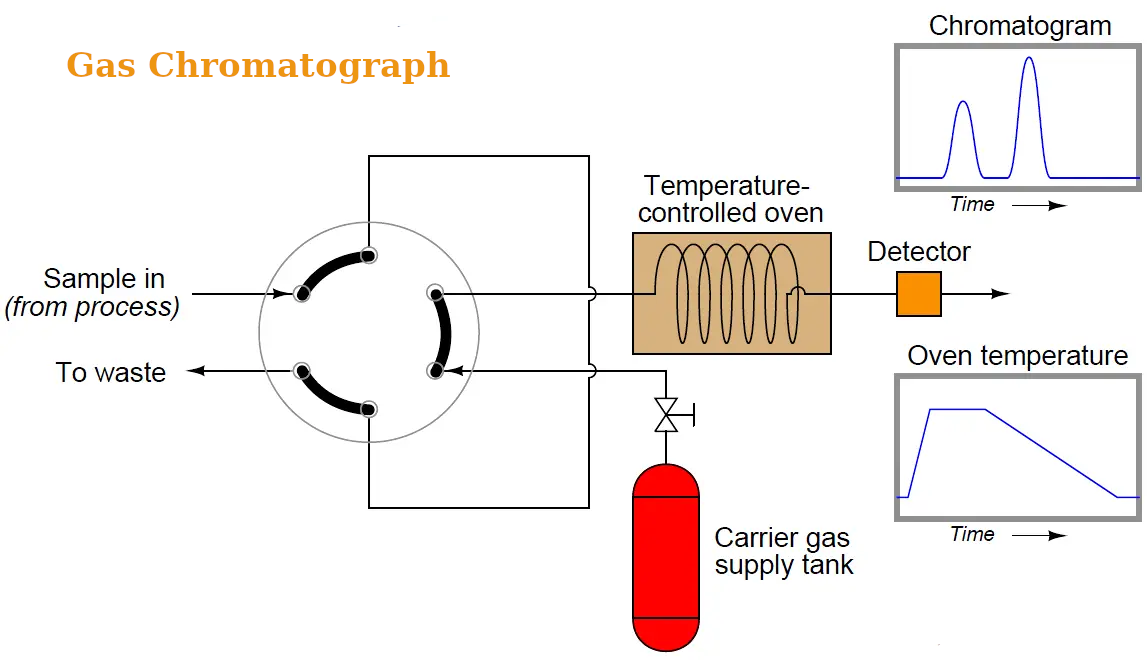

Gas gravity is typically measured using a device called a gas gravity balance. This instrument compares the buoyancy of a known volume of gas to that of air at the same temperature and pressure. Other methods include using a gas chromatograph or a density meter.

Understanding Gas Gravity Values:

- Gas gravity less than 1: This indicates a gas lighter than air, like methane (CH4).

- Gas gravity equal to 1: This indicates a gas with the same density as air.

- Gas gravity greater than 1: This indicates a gas heavier than air, like propane (C3H8).

Conclusion:

Gas gravity is a fundamental parameter in the oil and gas industry, influencing various operations from well testing to pipeline design. Understanding its significance and how it's measured helps professionals in the industry make informed decisions and optimize their processes. By accurately determining gas gravity, companies can ensure efficient and safe production, transportation, and sale of natural gas.

Test Your Knowledge

Gas Gravity Quiz

Instructions: Choose the best answer for each question.

1. What does gas gravity represent? a) The weight of a gas sample. b) The density of a gas compared to air. c) The volume of a gas at standard conditions. d) The pressure of a gas in a pipeline.

Answer

b) The density of a gas compared to air.

2. Which of the following has a gas gravity greater than 1? a) Methane (CH4) b) Propane (C3H8) c) Air d) Helium (He)

Answer

b) Propane (C3H8)

3. Why is gas gravity important in well testing? a) To determine the depth of the well. b) To calculate the flow rate of the well. c) To assess the composition and quality of the gas. d) To measure the pressure of the reservoir.

Answer

c) To assess the composition and quality of the gas.

4. How is gas gravity typically measured? a) With a pressure gauge. b) Using a gas chromatograph. c) With a gas gravity balance. d) By measuring the temperature of the gas.

Answer

c) With a gas gravity balance.

5. What is the significance of gas gravity in pipeline design? a) It helps determine the flow rate of the gas. b) It allows for accurate calculation of gas volume for billing purposes. c) It helps determine the size and pressure rating of the pipeline. d) All of the above.

Answer

d) All of the above.

Gas Gravity Exercise

Task:

A natural gas sample is analyzed and found to have a gas gravity of 0.65.

a) Is this gas lighter or heavier than air?

b) Based on this information, would you expect this gas to have a high or low heating value?

c) What are some potential applications of this type of gas?

Exercice Correction

**a) The gas is lighter than air** because its gas gravity is less than 1. **b) You would expect this gas to have a low heating value** because it is lighter than air. Lighter gases tend to be composed of more methane, which has a lower heating value compared to heavier hydrocarbons like propane. **c) Potential applications of this type of gas include:** * Fuel for power plants and industrial processes * Natural gas vehicles * Production of ammonia and other chemicals

Books

- "Petroleum Engineering Handbook" by John Lee (Comprehensive coverage of oil and gas engineering, including gas gravity)

- "Natural Gas Engineering Handbook" by John M. Campbell (Focuses on natural gas engineering and includes details on gas gravity)

- "Reservoir Engineering Handbook" by Tarek Ahmed (Covers reservoir characterization and production, touching upon gas gravity's role)

- "Fundamentals of Petroleum Engineering" by B.C. Craft and M.F. Hawkins (Introductory text covering basic principles of oil and gas engineering, including gas gravity)

Articles

- "Gas Gravity: Its Significance in Oil and Gas Operations" by [Author Name] (A detailed explanation of gas gravity, its applications, and measurement methods)

- "The Importance of Gas Gravity in Pipeline Design" by [Author Name] (Focuses on the role of gas gravity in pipeline design and safety)

- "Gas Gravity: A Key Parameter in Gas Sales and Billing" by [Author Name] (Explains how gas gravity is used in gas sales and billing)

- "Determining Gas Gravity in the Field" by [Author Name] (Provides practical guidance on measuring gas gravity using field instruments)

Online Resources

- Schlumberger: Gas Gravity (Technical article explaining gas gravity, its importance, and measurement techniques)

- American Petroleum Institute (API): Gas Gravity (Information on gas gravity standards and testing procedures)

- Society of Petroleum Engineers (SPE): Gas Gravity (Resources and articles on gas gravity related to oil and gas production)

Search Tips

- "Gas gravity oil and gas" (Find general information about gas gravity in the oil and gas industry)

- "Gas gravity measurement techniques" (Learn about various methods for measuring gas gravity)

- "Gas gravity calculation formula" (Find equations used to calculate gas gravity)

- "Gas gravity impact pipeline design" (Explore the role of gas gravity in pipeline design)

Techniques

Gas Gravity: A Comprehensive Overview

Introduction: (This section remains unchanged from the original text)

Gas Gravity: A Key Parameter in Oil & Gas Exploration and Production

In the world of oil and gas, understanding the properties of the substances you're working with is crucial. One important parameter used to characterize natural gas is gas gravity. This seemingly simple concept plays a vital role in various aspects of oil and gas exploration and production, from well testing to pipeline design.

What is Gas Gravity?

Gas gravity is a dimensionless number that represents the ratio of the density of a gas to the density of air at the same temperature and pressure. It essentially tells us how "heavy" a gas is compared to air. This ratio is also equal to the ratio of the molecular weight of the gas to the molecular weight of air (28.97).

Why is Gas Gravity Important?

Gas gravity has significant implications in various aspects of the oil and gas industry:

- Well Testing: During well testing, gas gravity helps determine the composition and quality of the produced gas. It can indicate the presence of heavier hydrocarbons like propane and butane, which have higher gas gravity values.

- Pipeline Design: The density of the gas affects the pressure and flow rates in pipelines. Knowing the gas gravity allows engineers to design pipelines that can safely and efficiently transport the gas.

- Gas Sales: Gas gravity is used to calculate the volume of gas sold based on its weight. This is important for accurate billing and pricing of natural gas.

- Reservoir Characterization: Gas gravity can provide insights into the composition and properties of the reservoir. This information helps in determining the potential productivity of the well.

Chapter 1: Techniques for Measuring Gas Gravity

Several techniques exist for measuring gas gravity, each with its own advantages and disadvantages. The choice of method depends on factors such as accuracy requirements, cost, and the available equipment.

Gas Gravity Balance: This traditional method uses a balance to compare the buoyancy of a known volume of gas against a reference (usually air). It provides a direct measurement of gas gravity and is relatively simple to operate. However, it can be slower than other methods and may be less accurate for complex gas mixtures.

Chromatographic Methods (Gas Chromatography - GC): Gas chromatography separates the individual components of a gas mixture, allowing for the determination of the composition and subsequent calculation of gas gravity based on the known molecular weights of the components. This provides a more detailed analysis than a simple gas gravity balance but requires specialized equipment and expertise.

Density Meters: These instruments directly measure the density of the gas, which can then be used to calculate gas gravity by comparing it to the density of air. Density meters are generally more accurate and faster than gas gravity balances, especially for high-pressure applications. Different types of density meters exist, including those based on pressure and those based on vibration.

Computational Methods: With advanced knowledge of the gas composition (often obtained through GC), gas gravity can be calculated using molecular weights and relative abundances of each component. This method is becoming more common due to improvements in compositional analysis technology.

Chapter 2: Models for Gas Gravity Calculation and Prediction

Once the gas composition is known (often from techniques described in Chapter 1), gas gravity can be calculated using various models. These models rely on the molecular weights and molar fractions of the individual components.

Ideal Gas Law Based Calculations: This is the simplest model and assumes ideal gas behavior. It uses the molecular weights of individual components and their mole fractions to calculate the average molecular weight of the mixture, which is then used to determine gas gravity. This model is appropriate for low-pressure gas mixtures.

Real Gas Models (e.g., Peng-Robinson, Redlich-Kwong): These models account for the non-ideal behavior of real gases, particularly at higher pressures. They provide more accurate predictions of gas gravity under various conditions. Selecting the right model depends on the specific gas composition and pressure range.

Empirical Correlations: Some empirical correlations have been developed to estimate gas gravity based on easily measurable parameters, such as specific gravity of the liquid phase or other easily accessible measurements. These correlations are often used as a quick estimation but may have limited accuracy.

Chapter 3: Software for Gas Gravity Calculation and Analysis

Several software packages are available for performing gas gravity calculations and analysis:

Specialized Oil & Gas Engineering Software: Many commercial reservoir simulation and process simulation packages include modules for gas gravity calculation and analysis, often integrating with other reservoir properties and flow simulations. Examples include (mention relevant software, e.g., CMG, Eclipse, etc. – avoid specific product endorsements if not possible).

Spreadsheet Software (e.g., Excel): Spreadsheets can be used to create custom calculators for gas gravity based on the appropriate models and equations. This offers flexibility but requires careful development and validation.

Proprietary Software Packages: Some companies may have developed their own proprietary software for gas gravity analysis, tailored to their specific needs and data formats.

Chapter 4: Best Practices in Gas Gravity Measurement and Application

Calibration and Maintenance: Regular calibration and maintenance of equipment used for gas gravity measurement is crucial to ensure accuracy and reliability of results.

Quality Control: Implementing robust quality control procedures throughout the measurement and calculation process is essential for accurate and reliable results.

Data Handling: Proper data handling and management are crucial, ensuring the traceability of gas gravity data and its integration with other reservoir and production data.

Safety Considerations: Safety precautions should always be followed during gas handling and measurement, especially with potentially hazardous gases.

Appropriate Model Selection: Choosing the right model for gas gravity calculation (ideal vs. real gas) based on pressure and temperature conditions is crucial for accurate results.

Chapter 5: Case Studies on Gas Gravity Applications

(This section requires specific examples and data that are not provided in the original text. Below is a template for structuring case studies. Replace the bracketed information with actual examples.)

Case Study 1: [Company Name] - Optimizing Pipeline Design

This case study will detail how [Company Name] used gas gravity measurements to optimize the design of a new gas pipeline, leading to [quantifiable benefit, e.g., cost savings, increased efficiency]. It will include details on the measurement techniques employed, the gas composition, and the impact of accurate gas gravity data on the design process.

Case Study 2: [Reservoir Name] - Reservoir Characterization and Production Forecasting

This case study will show how gas gravity analysis, combined with other reservoir data, helped characterize the [Reservoir Name] reservoir and improve production forecasting. The case study will describe the techniques used to measure gas gravity from the reservoir and how this information was incorporated into reservoir simulation models to enhance predictive capabilities.

Case Study 3: [Gas Processing Facility] - Gas Sales and Revenue Optimization

This case study will demonstrate how accurate gas gravity measurement is essential for fair and accurate gas sales billing and pricing at a gas processing facility. It will show the economic impact of precise gas gravity determination on revenue streams.

This expanded structure provides a more comprehensive overview of gas gravity, suitable for a technical report or in-depth article. Remember to replace the bracketed information in Chapter 5 with real-world examples and data to enhance its value.

- Base Gas Understanding Base Gas in Nat…

- Continuous Flow Gas Lift Continuous Flow Gas Lift: A S…

- Conventional Gas Unlocking the Power of Conven…

- Cushion Gas Cushion Gas: A Vital Componen…

- Cycle Gas Cycle Gas: The Fuel that Keep…

- Dissolved Gas Understanding Dissolved Gas: …

- dissolved-gas drive The Power of Bubbles: Underst…

- Dissolved Gas Drive Dissolved Gas Drive: The Powe…

- Biogenic Gas Unlocking the Secrets of Biog…

- Blue Gas Blue Gas: The Invisible Treas…

- Casing Head Gas and Gasoline Casing Head Gas: A Valuable R…

- Coal Gas Coal Gas: A Forgotten Fuel So…

- Degasser Degassing in Oil & Gas: Keepi…

- Bottom Hole Gas Separator Bottom Hole Gas Separator: A …

- Connection Gas Connection Gas: A Telltale Si…

- Degasser Degassing: A Vital Step in Dr…

- Coal gasification Coal Gasification: Unleashing…

- Combustible Limits (fuel gas) Combustible Limits: The Explo…

- Control Gas Control Gas: The Unsung Hero …

- Decompression Damage (gas effects on seals) Decompression Damage: A Silen…

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments