Drilling & Well Completion

Deviation Angle

Understanding Inclination: The Angle That Shapes Your Well

In the world of drilling and well construction, "inclination" is a crucial term that describes the angle a wellbore deviates from the vertical. This angle, measured in degrees, plays a vital role in determining the trajectory of the well and influences several important factors, including:

1. Reaching Targets: Inclination allows drillers to reach subsurface targets that are not directly beneath the surface drilling location. This is particularly important for accessing oil and gas reserves located at a distance from the drilling platform.

2. Minimizing Environmental Impact: By drilling horizontally or at an angle, drillers can minimize surface disturbance and avoid sensitive areas like forests or water bodies.

3. Optimizing Production: Inclination allows for the creation of complex wellbores that can intersect multiple producing zones or maximize the contact area with a reservoir.

4. Navigating Complex Formations: Inclination helps navigate challenging formations like faults and fractures, allowing for safer and more efficient drilling.

How is Inclination Measured?

Inclination is measured using specialized tools called "downhole survey instruments" which are deployed into the wellbore during drilling operations. These instruments use various technologies to determine the angle of the wellbore relative to the vertical.

Types of Inclination:

- Vertical: Inclination of 0 degrees, where the wellbore is drilled straight down.

- Horizontal: Inclination of 90 degrees, where the wellbore is drilled parallel to the surface.

- Directional: Inclination between 0 and 90 degrees, allowing for a variety of angled drilling trajectories.

The Impact of Inclination on Well Construction:

- Drilling Complexity: Drilling at an angle increases the complexity of the operation and requires specialized equipment and expertise.

- Wellbore Stability: The inclination angle can impact the stability of the wellbore, requiring careful monitoring and potential wellbore strengthening techniques.

- Production Efficiency: The inclination can influence the flow of fluids within the wellbore and ultimately impact production rates.

Understanding inclination is crucial for successful well construction and resource extraction. By carefully planning and controlling the inclination angle, engineers and drillers can optimize wellbore trajectory, minimize environmental impact, and maximize production efficiency.

Test Your Knowledge

Quiz: Understanding Inclination

Instructions: Choose the best answer for each question.

1. What is the primary purpose of inclination in well drilling?

(a) To reach subsurface targets not directly below the drilling location. (b) To increase the complexity of drilling operations. (c) To minimize the use of specialized drilling equipment. (d) To ensure the wellbore remains vertical.

Answer

(a) To reach subsurface targets not directly below the drilling location.

2. Which type of inclination allows for a variety of angled drilling trajectories?

(a) Vertical (b) Horizontal (c) Directional (d) Inclined

Answer

(c) Directional

3. What is the inclination angle of a wellbore drilled parallel to the surface?

(a) 0 degrees (b) 45 degrees (c) 90 degrees (d) 180 degrees

Answer

(c) 90 degrees

4. Which of the following is NOT a factor influenced by inclination?

(a) Environmental impact (b) Production efficiency (c) Wellbore stability (d) The type of drilling rig used

Answer

(d) The type of drilling rig used

5. What tools are used to measure inclination during drilling operations?

(a) Surface surveying equipment (b) Downhole survey instruments (c) Seismic imaging tools (d) Geological mapping software

Answer

(b) Downhole survey instruments

Exercise: Calculating Inclination

Instructions: Imagine you are drilling a well with a horizontal displacement of 500 meters and a vertical depth of 1000 meters. Calculate the inclination angle of the wellbore.

Formula: Inclination Angle (degrees) = arctan(Horizontal Displacement / Vertical Depth)

Hint: You will need a calculator to find the arctangent (tan⁻¹) of the result.

Exercise Correction

Here's how to solve the problem: 1. **Identify the values:** - Horizontal Displacement = 500 meters - Vertical Depth = 1000 meters 2. **Apply the formula:** - Inclination Angle = arctan (500 / 1000) - Inclination Angle = arctan (0.5) 3. **Calculate the arctangent:** - Inclination Angle ≈ 26.57 degrees **Therefore, the inclination angle of the wellbore is approximately 26.57 degrees.**

Books

- "Wellbore Trajectory Design and Control" by R.E. Johnston and J.R. Williamson: A comprehensive guide covering various aspects of wellbore trajectory, including deviation angle, planning, and measurement.

- "Petroleum Engineering: Drilling and Well Completions" by M.J. Economides and K.G. Nolte: This textbook provides an in-depth exploration of drilling operations, including the role of deviation angle and its implications.

- "Drilling Engineering: A Comprehensive Approach" by R.F. Mitchell: This book offers a detailed examination of drilling engineering principles, with sections dedicated to wellbore trajectory and deviation angle management.

Articles

- "Directional Drilling: A Review of Its History and Applications" by S.A. Holditch: This article provides a historical perspective on directional drilling and the evolving role of deviation angle in accessing oil and gas reserves.

- "The Impact of Deviation Angle on Wellbore Stability" by J.R. Williamson and R.E. Johnston: This research article delves into the relationship between deviation angle and wellbore stability, analyzing potential issues and mitigation strategies.

- "Optimizing Wellbore Trajectory for Enhanced Production" by K.G. Nolte and M.J. Economides: This article explores the impact of deviation angle on production efficiency and discusses techniques for optimizing wellbore trajectory to maximize resource recovery.

Online Resources

- Society of Petroleum Engineers (SPE): This organization offers a wealth of resources on drilling and wellbore engineering, including articles, conferences, and training materials. Search for "deviation angle" or "wellbore trajectory" to find relevant information.

- OnePetro: This platform provides access to a vast library of technical papers and research related to oil and gas exploration and production. Search for "deviation angle" to find related content.

- Drillinginfo: This company offers data and analysis on drilling operations, including information on deviation angle and wellbore trajectory.

Search Tips

- Use specific keywords like "deviation angle," "wellbore trajectory," "directional drilling," "inclination angle," and "wellbore design."

- Combine keywords with specific drilling aspects, such as "deviation angle stability," "deviation angle optimization," or "deviation angle measurement."

- Refine your search using operators like "AND" and "OR" to narrow down results.

- Use quotes around specific phrases to find exact matches.

- Consider including relevant industry terms or acronyms.

Techniques

Deviation Angle: A Comprehensive Guide

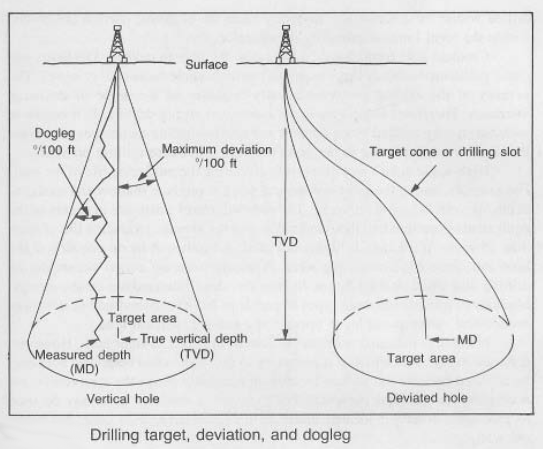

This document expands on the concept of deviation angle (here used interchangeably with inclination) in well drilling, breaking it down into key aspects. The image provided, showing a wellbore deviating from vertical, serves as a visual aid throughout.

Chapter 1: Techniques for Measuring and Controlling Deviation Angle

This chapter details the practical methods used to measure and control the deviation angle during drilling operations.

1.1 Measurement Techniques:

Downhole Survey Instruments: These tools, deployed within the wellbore, utilize various technologies to determine the wellbore's inclination and azimuth (direction). Common technologies include:

- Magnetic Measurement: Utilizes Earth's magnetic field to determine orientation. Susceptible to magnetic interference.

- Gyroscopic Measurement: Employs gyroscopes to measure the wellbore's orientation independently of magnetic fields. More accurate than magnetic measurements, especially in areas with magnetic anomalies.

- Accelerometer and Inclinometer Measurement: Uses accelerometers to measure gravity and inclinometers to measure the angle of inclination. Provides highly accurate measurements, often combined with other techniques.

- Combination Tools: Modern tools often integrate multiple technologies for improved accuracy and redundancy.

Survey Frequency: The frequency of surveys depends on the complexity of the well trajectory and the required accuracy. More frequent surveys are necessary in highly deviated wells or complex geological formations.

Data Processing and Interpretation: Raw survey data needs processing to account for tool errors, magnetic interference, and other factors to generate an accurate wellbore trajectory. Software plays a crucial role in this process.

1.2 Controlling Deviation Angle:

- Directional Drilling Techniques: These techniques are crucial for controlling the wellbore trajectory, ensuring it reaches the desired target while maintaining the planned deviation angle. Common techniques include:

- Bent Sub: A specialized drill collar with a built-in bend that steers the drill bit.

- Mud Motors: These motors rotate the drill bit independently of the drill string, allowing for precise directional control.

- Rotary Steerable Systems (RSS): Advanced systems that use sensors and actuators to actively control the drill bit's direction and inclination. They offer greater precision and automation than traditional methods.

- Geosteering: Real-time adjustments to the wellbore trajectory based on formation evaluation data acquired during drilling.

Chapter 2: Models for Predicting and Simulating Deviation Angle

This chapter covers the mathematical and computational models used to predict and simulate wellbore trajectories.

Trajectory Planning Software: Before drilling commences, software models are used to plan the optimal wellbore trajectory based on geological data, target location, and drilling constraints. These models incorporate various factors, including the expected formation properties and the planned directional drilling techniques.

Wellbore Stability Models: These models predict the potential for wellbore instability (e.g., collapses, breakouts) based on the planned deviation angle and the formation's mechanical properties. This information helps to determine appropriate wellbore strengthening techniques.

Simulation Software: Simulations allow engineers to test different drilling scenarios and optimize the wellbore trajectory before actual drilling begins, reducing the risk of costly deviations from the planned path. These simulations consider various parameters, such as formation properties, drilling parameters, and tool behavior.

Chapter 3: Software for Deviation Angle Management

This chapter focuses on the software used in the process.

Trajectory Planning Software: Examples include Petrel, Landmark, and Kingdom. These programs facilitate the design of well trajectories, including the specification of deviation angles at various depths.

Downhole Survey Processing Software: Software dedicated to processing and interpreting data from downhole survey instruments. This ensures accurate determination of wellbore trajectory and deviation angles.

Geosteering Software: Software that integrates real-time data from formation evaluation tools with wellbore trajectory models to guide the drilling process and maintain the desired deviation angle.

Wellbore Stability Software: This software analyzes the stresses on the wellbore and predicts the potential for instability based on the planned deviation angle.

Chapter 4: Best Practices for Deviation Angle Management

This chapter highlights best practices to ensure accurate and efficient deviation angle control.

Accurate Pre-Drill Planning: Thorough geological characterization and trajectory planning are essential.

Regular Downhole Surveys: Frequent surveys ensure accurate tracking of the wellbore trajectory and enable timely corrections if needed.

Careful Selection of Directional Drilling Techniques: Choosing appropriate techniques based on wellbore complexity, formation properties, and other factors.

Real-time Monitoring and Control: Continuous monitoring of wellbore trajectory and parameters allows for immediate response to any deviations.

Experienced Personnel: Highly trained personnel are crucial for successful directional drilling operations.

Chapter 5: Case Studies of Deviation Angle Management

This chapter provides real-world examples illustrating the importance of proper deviation angle management.

Case Study 1: Successful Extended Reach Drilling: A case study demonstrating how precise control of deviation angle enabled the successful drilling of an extended-reach well, accessing a remote reservoir.

Case Study 2: Managing Wellbore Instability: A case study detailing how wellbore stability modeling and appropriate drilling techniques prevented wellbore collapse in a challenging geological formation.

Case Study 3: Optimizing Production Through Multilateral Wells: A case study demonstrating how strategic control of deviation angle in multilateral wells maximized contact with multiple producing zones, enhancing production efficiency.

This comprehensive guide provides a thorough overview of deviation angle management in well drilling. The information presented aims to improve understanding and facilitate safer, more efficient, and cost-effective drilling operations.

- Build Angle Understanding Build Angle in …

- Deviation Survey Navigating the Underground: U…

- High Angle Well High Angle Wells: Drilling De…

- Right Angle Set Right Angle Set: A Critical F…

- Sail Angle Understanding Sail Angle in D…

- Contact Angle The Angle of Attraction: Unde…

- Deviation Deviation: Navigating the Unf…

- Deviation Navigating the Deviations in …

- Deviation Permit Deviation Permit: Navigating …

- Standard Deviation Standard Deviation: Navigatin…

- Application for Expenditure Justification Navigating the Appl… Project Planning & Scheduling

- Budgeted Cost of Work Scheduled ("BCWS") Understanding Budge… Cost Estimation & Control

- Battery limit Understanding Batte… General Technical Terms

- DV Tool (cementing) DV Tool: A Crucial … Drilling & Well Completion

- TOC TOC: Understanding … General Technical Terms

Comments