معالجة النفط والغاز

Hydrocyclone

الدوامات المائية: دوامة الفصل في صناعة النفط والغاز

الدوامات المائية، المعروفة أيضًا باسم الأعاصير، هي قطع معدات متعددة الاستخدامات تُستخدم على نطاق واسع في صناعة النفط والغاز. إنها عبارة عن أجهزة مخروطية الشكل تُستغل القوة الطاردة المركزية فيها لفصل السوائل والجسيمات الصلبة المُشتتة فيها. هذه عملية الفصل ضرورية للعديد من العمليات، بما في ذلك:

1. إزالة الرمل:

تُعد الدوامات المائية ضرورية لإزالة الرمل وغيره من الجسيمات الصلبة من السوائل المنتجة (النفط والغاز والمياه) قبل وصولها إلى معدات المعالجة في المراحل التالية. هذه المواد الصلبة قد تسبب التآكل، والانسداد، وحتى تلف المعدات القيمة. من خلال تدوير السائل بسرعة، تُطرح الجسيمات الرملية الثقيلة إلى الخارج وتُترسب في قاع المخروط، بينما يتم تفريغ السوائل الأخف وزنا من الأعلى.

2. إزالة الرمل:

إزالة الرمل هي خطوة أساسية في معالجة المياه المنتجة قبل إمكانية تفريغها بأمان أو إعادة استخدامها. تُزيل الدوامات المائية بشكل فعال الرمل والطمي وغيره من المواد الصلبة من الماء، مما يقلل من خطر الانسداد ويُحسّن من جودة المياه بشكل عام.

3. التجفيف:

يمكن استخدام الدوامات المائية لفصل الماء عن النفط والغاز، مما يقلل من محتوى الماء في السوائل المنتجة. هذه العملية، المعروفة باسم التجفيف، ضرورية لتحسين كفاءة المعالجة في المراحل التالية وتكثيف قيمة الهيدروكربونات المستخرجة.

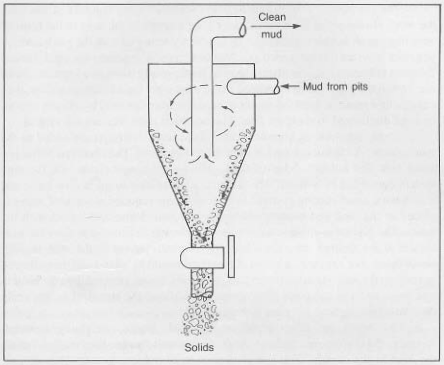

4. إزالة المواد الصلبة من سوائل الحفر:

سوائل الحفر، التي تُستخدم لتزييت وتبريد رؤوس الحفر، قد تتلوث بالمواد الصلبة أثناء عمليات الحفر. تُزيل الدوامات المائية بشكل فعال هذه المواد الصلبة، مما يضمن كفاءة وأمان عملية الحفر.

كيف تعمل:

المبدأ وراء عمل الدوامات المائية بسيط وفعال:

- التغذية المماسية: يُدخل خليط السوائل إلى الدوامة المائية بشكل مماس، مما يخلق حركة دوارة مثل دوامة.

- القوة الطاردة المركزية: بينما يدور السائل، تجذب القوة الطاردة المركزية المواد الصلبة الأثقل نحو خارج المخروط.

- الفصل: تُترسب المواد الصلبة الأثقل في قاع المخروط ويتم تفريغها كتيار مركز، بينما يتم تفريغ السوائل الأخف وزنا من الأعلى.

مزايا الدوامات المائية:

- البساطة والصيانة المنخفضة: تُعد الدوامات المائية بسيطة التصميم ولديها عدد قليل من الأجزاء المتحركة، مما يتطلب صيانة محدودة.

- الكفاءة: يمكنها تحقيق كفاءات فصل عالية، مما يُزيل بشكل فعال حتى الجسيمات الصلبة الصغيرة.

- الفعالية من حيث التكلفة: مقارنةً بتقنيات الفصل الأخرى، غالبًا ما تكون الدوامات المائية أكثر فعالية من حيث التكلفة من حيث الاستثمار الأولي وتكاليف التشغيل.

- التنوع: يمكن استخدام الدوامات المائية لمجموعة واسعة من التطبيقات، بما في ذلك أنواع مختلفة من السوائل وأحجام الجسيمات الصلبة.

الخلاصة:

تُعد الدوامات المائية أدوات ضرورية في صناعة النفط والغاز، حيث تلعب دورًا حاسمًا في العديد من العمليات، بدءًا من إزالة الرمل إلى التجفيف. يجعلها تصميمها البسيط وكفاءتها العالية وفعاليته من حيث التكلفة ضرورية للحفاظ على التشغيل السلس والموثوق به لمرافق النفط والغاز، مما يساهم في النهاية في الإنتاج الفعال والآمن للموارد القيمة.

Test Your Knowledge

Hydrocyclone Quiz

Instructions: Choose the best answer for each question.

1. What is the primary function of a hydrocyclone?

a) To mix fluids and solids b) To separate fluids and solids c) To heat fluids d) To cool fluids

Answer

b) To separate fluids and solids

2. Which of the following is NOT a common application of hydrocyclones in the oil and gas industry?

a) Sand removal b) Desanding c) Dehydration d) Water injection

Answer

d) Water injection

3. What force is primarily responsible for the separation process in a hydrocyclone?

a) Gravity b) Magnetic force c) Centrifugal force d) Electrostatic force

Answer

c) Centrifugal force

4. Which of the following is an advantage of using hydrocyclones?

a) High maintenance requirements b) Low separation efficiency c) High capital investment costs d) Simplicity and low maintenance

Answer

d) Simplicity and low maintenance

5. How does the fluid enter a hydrocyclone?

a) From the bottom, vertically b) From the top, vertically c) Tangentially, creating a swirl d) Horizontally, without any swirl

Answer

c) Tangentially, creating a swirl

Hydrocyclone Exercise

Scenario: You are working on a drilling rig and the drilling mud is becoming too thick due to excessive solid particles. A hydrocyclone is used to remove these solids. Explain how the hydrocyclone would work in this scenario to improve the drilling fluid.

Exercice Correction

The drilling mud is pumped into the hydrocyclone tangentially, creating a swirling motion. This swirling motion generates centrifugal force, which pushes the heavier solid particles outwards towards the wall of the cone. These solids then settle at the bottom of the cone and are discharged as a concentrated stream, known as the underflow. The lighter, cleaner drilling fluid exits the top of the cone, known as the overflow, and is recirculated back into the drilling system. This process effectively removes the excess solids from the drilling mud, reducing its viscosity and improving its ability to lubricate and cool the drill bit.

Books

- "Hydrocyclones: Principles and Applications" by G. T. Gillespie and J. D. Wilson: This comprehensive book provides a detailed overview of hydrocyclone theory, design, and applications in various industries, including oil and gas.

- "Separation Technology in the Oil and Gas Industry" edited by A. L. Kohl and R. Nielsen: This volume includes a chapter on hydrocyclones, discussing their application in oil and gas processing.

- "Handbook of Separation Techniques for Chemical Engineers" edited by P. A. Schweitzer: Contains a chapter on centrifugal separators, which covers the principles of hydrocyclones and their use in various industries.

Articles

- "Hydrocyclones: A Powerful Tool for Sand Removal in Oil and Gas Production" by J. P. Smith: Provides a practical overview of hydrocyclone application in sand removal, covering design considerations and performance optimization.

- "Hydrocyclone Performance in Oilfield Applications: A Review" by M. J. Brown: This review article analyzes the efficiency and limitations of hydrocyclones in various oilfield applications, including desanding and dehydration.

- "The Use of Hydrocyclones for Desanding in Oil and Gas Production" by K. L. Jones: Discusses the specific challenges and solutions related to desanding in oil and gas production using hydrocyclones.

- "Hydrocyclones for Solids Removal from Drilling Fluids" by R. T. Davis: Examines the role of hydrocyclones in removing solids from drilling fluids, highlighting their impact on drilling efficiency and wellbore stability.

Online Resources

- "Hydrocyclones" on Wikipedia: Provides a basic overview of hydrocyclones, covering their history, principles, and applications.

- "Hydrocyclones" on the website of the American Society of Mechanical Engineers (ASME): Offers technical resources and information on hydrocyclone design and operation, including industry standards.

- "Hydrocyclones in the Oil and Gas Industry" by Schlumberger: Provides a case study highlighting the successful use of hydrocyclones for sand removal in oil and gas production.

Search Tips

- Use specific keywords: "hydrocyclones oil and gas", "hydrocyclones sand removal", "hydrocyclones desanding", "hydrocyclones drilling fluids"

- Use quotation marks for specific phrases: "hydrocyclone efficiency"

- Combine keywords with industry names: "hydrocyclones in oil and gas industry"

- Use site: operator to target specific websites: "site:slb.com hydrocyclones"

Techniques

Hydrocyclones in Oil & Gas: A Comprehensive Guide

This guide breaks down the crucial aspects of hydrocyclones in the oil and gas industry, covering techniques, models, software, best practices, and case studies.

Chapter 1: Techniques

The effectiveness of a hydrocyclone hinges on understanding and optimizing several key techniques:

Tangential Inlet Design: The angle and geometry of the tangential inlet significantly influence the vortex formation and separation efficiency. Precise design is crucial for maximizing centrifugal force and minimizing pressure loss. Variations include single-inlet, multiple-inlet, and spiral-inlet designs, each with its own advantages depending on the application and particle size distribution.

Vortex Finder and Apex Design: The shape and size of the vortex finder (the central tube) controls the overflow rate of the clarified fluid. The apex design influences the underflow concentration and discharge. Optimizing these elements is key to achieving the desired separation sharpness.

Underflow and Overflow Discharge Configurations: The design and placement of the underflow and overflow discharge points affect the separation efficiency and pressure drop. Precise control over these parameters is crucial to avoid recirculation and maintain the desired separation. Techniques like using adjustable spouts or vortex breakers can enhance separation.

Pressure Control and Optimization: The inlet pressure significantly impacts the centrifugal force and consequently, the separation efficiency. Optimizing pressure is critical and often involves balancing efficiency against energy consumption. Techniques like pressure regulation valves and monitoring systems help achieve this.

Chapter 2: Models

Various hydrocyclone models exist, each tailored to specific applications and fluid characteristics:

Conventional Hydrocyclones: These are the most common type, characterized by their simple conical shape and relatively low pressure drop. They are effective for a wide range of applications but may not be optimal for very fine particle separation.

High-efficiency Hydrocyclones: These designs incorporate features like optimized vortex finders and improved inlet geometries to achieve higher separation efficiencies, especially for finer particles. They often have higher pressure drops than conventional designs.

Multi-stage Hydrocyclones: These systems connect multiple hydrocyclones in series, increasing the overall separation efficiency. Each stage handles a specific particle size range, improving the overall removal of solids.

Specialized Hydrocyclones: Specialized designs cater to specific needs, such as those used for high-viscosity fluids or those incorporating magnetic fields for enhanced separation of magnetic particles.

Chapter 3: Software

Computational Fluid Dynamics (CFD) software plays a vital role in hydrocyclone design and optimization:

CFD Simulation: Software such as ANSYS Fluent, COMSOL Multiphysics, and OpenFOAM allow engineers to simulate the fluid flow and particle separation within a hydrocyclone. This helps optimize design parameters and predict performance before physical construction.

Particle Tracking: Specialized modules within CFD software track the movement of individual particles, enabling accurate prediction of separation efficiency and particle size distribution in the underflow and overflow streams.

Optimization Algorithms: These tools automate the design optimization process, exploring different design parameters to identify the optimal configuration based on specified performance criteria.

Chapter 4: Best Practices

Effective hydrocyclone operation requires adherence to best practices:

Regular Inspection and Maintenance: Regular inspections are essential to identify and address potential issues like wear and tear, blockages, or leaks, ensuring continuous optimal performance. Preventive maintenance schedules should be implemented.

Feed Preparation: Proper preparation of the feed stream is crucial. This involves pre-screening to remove oversized particles that could damage the hydrocyclone and ensuring a consistent feed flow rate to maintain optimal separation.

Monitoring and Control: Continuous monitoring of key parameters like pressure, flow rate, and underflow/overflow concentrations allows for early detection of operational problems and enables timely adjustments.

Proper Material Selection: Selecting appropriate materials based on the corrosive nature of the fluids and the abrasive nature of the solids is vital to ensure the longevity of the hydrocyclone.

Chapter 5: Case Studies

Real-world examples demonstrate the versatility and effectiveness of hydrocyclones:

Case Study 1: Sand Removal from Produced Water: A case study could detail a specific oil and gas production facility where hydrocyclones were implemented to effectively remove sand from produced water, reducing downstream equipment wear and improving water discharge quality. Quantifiable results like percentage of sand removed and cost savings would be included.

Case Study 2: Dehydration of Crude Oil: Another case study could focus on the use of hydrocyclones for dehydrating crude oil, illustrating how these devices improved the efficiency of downstream processing and minimized the water content in the final product. Performance metrics such as water content reduction and throughput would be highlighted.

Case Study 3: Solids Removal from Drilling Fluids: A case study focusing on drilling operations would show how hydrocyclones significantly reduced solids content in drilling fluids, maintaining drilling efficiency and reducing the need for frequent fluid replacement. Metrics like reduced downtime and improved drilling rate could be presented.

This comprehensive guide offers a detailed understanding of hydrocyclones and their application in the oil and gas industry. By understanding the techniques, models, software, best practices, and case studies presented, engineers and operators can optimize their use and maximize efficiency.

- طلب تبرير المصروفات طلب مبرر الإنفاق: د… تخطيط وجدولة المشروع

- التكلفة الميزانية للعمل المجدول فهم تكلفة العمل الم… تقدير التكلفة والتحكم فيها

- حدود البطارية فهم حدود البطارية ف… المصطلحات الفنية العامة

- أداة الصمام السفلي أداة الصمام السفلي:… الحفر واستكمال الآبار

- جدول المحتويات TOC: فهم قمة الإسمن… المصطلحات الفنية العامة

Comments