الحفر واستكمال الآبار

horsepower

قوة الحصان: البطل الخفي في حفر الآبار وإكمالها

في عالم حفر الآبار وإكمالها، لا تُعد قوة الحصان مجرد وحدة قياس – بل هي القوة الدافعة وراء كل عملية. ففهم قوة الحصان أمر ضروري لتحسين الأداء، وضمان السلامة، وبالتالي تحقيق النجاح في استخراج الموارد القيمة من باطن الأرض.

تعريف قوة الحصان:

تُحدد قوة الحصان (hp) معدل إنجاز العمل. تُمثل قوة الحصان الواحدة كمية الطاقة المطلوبة لرفع 550 رطلًا قدمًا واحدًا في ثانية واحدة. يتحول هذا التعريف البسيط إلى قدرة الجهاز على أداء كمية محددة من العمل في فترة زمنية معينة. في حفر الآبار وإكمالها، تُشغل قوة الحصان الآلات القوية التي تُؤدي المهام الصعبة مثل الحفر، والتثبيت، والتكسير الهيدروليكي.

قوة الحصان في العمل:

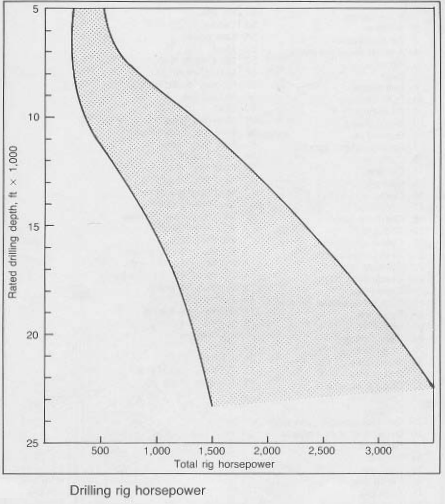

- منصات الحفر: تُشغل قوة الحصان طاولات الدوران، ومضخات الطين، ونظم الرفع التي تدفع عمليات الحفر. تعتمد الطاقة المطلوبة لمنصة الحفر على عوامل متعددة مثل العمق، وصعوبة التكوين، وخصائص سائل الحفر. تُعني قوة الحصان الأعلى قدرة حفر أكبر وكفاءة أعلى.

- عمليات التثبيت: تتطلب خلط عجينة الأسمنت لعملية تثبيت بئر الآبار قوة حصان كبيرة لضمان الخلط والحقن الصحيحين. تُؤمن قوة الحصان الكافية خليطًا سلسًا ومتسقًا، مما يؤدي إلى تثبيت ناجح.

- عمليات التكسير الهيدروليكي: تعتمد مضخات الضغط العالي، التي تُشكل جزءًا أساسيًا من التكسير الهيدروليكي، بشكل كبير على قوة الحصان لتوفير القوة اللازمة لخلق شقوق في التكوين وإطلاق الهيدروكربونات. تُعني قوة الحصان الأعلى تكسيرًا أسرع وأكثر كفاءة، مما يُعظم الإنتاج.

ما وراء الأرقام:

بينما تُعد القيمة الرقمية لقوة الحصان أساسية، فمن المهم أيضًا مراعاة السياق. في حفر الآبار وإكمالها، لا تُمثل قوة الحصان مجرد قوة غاشمة – بل تُمثل أيضًا:

- الكفاءة: يُتيح تحسين استخدام قوة الحصان تحقيق أقصى إنتاج بأقل استهلاك للطاقة، مما يؤدي إلى توفير التكاليف وتقليل التأثير البيئي.

- السلامة: تُؤمن قوة الحصان الكافية قدرة المعدات على التعامل مع متطلبات العملية، مما يمنع الأعطال والمخاطر المحتملة للسلامة.

- الموثوقية: تُعد قوة الحصان المتسقة ضرورية للحفاظ على العمليات المستمرة، وتقليل وقت التوقف عن العمل وتكثيف الإنتاج.

مستقبل قوة الحصان:

مع تطور الصناعة، يظل دور قوة الحصان يتكيف. تُقدم التطورات التكنولوجية، مثل منصات الحفر الكهربائية والهجينة، طرقًا جديدة لاستخدام وإدارة الطاقة. ومع ذلك، يظل المفهوم الأساسي لقوة الحصان كقياس للعمل محوريًا للتشغيل الفعال والناجح لأنشطة حفر الآبار وإكمالها.

في الختام، تُعد قوة الحصان العمود الفقري لحفر الآبار وإكمالها. ففهم دورها وتحسين تطبيقها أمران حاسمان لضمان عمليات ناجحة، وتكثيف الكفاءة، وتحقيق الربحية في هذه الصناعة المُطالبة والحيوية.

Test Your Knowledge

Horsepower Quiz:

Instructions: Choose the best answer for each question.

1. What does horsepower measure? a) The amount of work done in a given time. b) The speed of a machine. c) The size of a machine. d) The weight a machine can lift.

Answer

a) The amount of work done in a given time.

2. Which of these operations DOES NOT directly rely on horsepower? a) Drilling. b) Cementing. c) Fracking. d) Well logging.

Answer

d) Well logging.

3. What is a benefit of optimizing horsepower usage? a) Increased safety risks. b) Lower operating costs. c) Reduced drilling speed. d) Increased environmental impact.

Answer

b) Lower operating costs.

4. What is the main advantage of using more horsepower in a fracking operation? a) Reduced risk of wellbore collapse. b) Faster and more efficient fracturing. c) Reduced environmental impact. d) Increased drilling depth.

Answer

b) Faster and more efficient fracturing.

5. Why is reliable horsepower delivery important in drilling and well completion? a) To prevent breakdowns and downtime. b) To reduce drilling speed. c) To increase drilling depth. d) To reduce the need for maintenance.

Answer

a) To prevent breakdowns and downtime.

Horsepower Exercise:

Scenario: A drilling rig is operating at a depth of 10,000 feet. The drilling mud pump has a horsepower rating of 1,500 hp. The rig operator notices a decrease in drilling rate and suspects the pump may be underpowered.

Task: Research the factors that affect drilling rate and explain how horsepower plays a role in the drilling process. Based on the scenario, provide possible reasons why the drilling rate may have decreased despite the high horsepower rating of the pump.

Exercice Correction

**Factors Affecting Drilling Rate:** * **Formation Hardness:** Harder formations require more power to penetrate. * **Drilling Fluid Properties:** Viscosity and density of the mud affect the drilling rate. * **Bit Type and Size:** Larger, more aggressive bits require higher horsepower. * **Hole Diameter:** Larger hole diameters require more mud circulation and horsepower. * **Mud Pump Capacity:** Insufficient mud pump horsepower can limit the rate of penetration. **Possible Reasons for Decreased Drilling Rate:** * **Formation Change:** The drilling rig might have encountered a harder rock layer, requiring more power. * **Mud Pump Malfunction:** The pump may not be operating at full capacity due to a mechanical issue, even though it has a high horsepower rating. * **Bit Wear:** A worn-out drill bit can reduce drilling efficiency. * **Hole Stability Issues:** Problems with hole stability (e.g., cavings) can slow down drilling progress. **Horsepower Role:** Horsepower is critical in providing the necessary energy to circulate the drilling mud, which in turn helps to remove cuttings, cool the bit, and maintain hole stability. Insufficient horsepower can lead to decreased drilling rate, increased wear on the bit, and potential wellbore stability issues.

Books

- Drilling Engineering: Principles and Practices by M.E. Economides and K.G. Nolte (This comprehensive text covers drilling operations in detail, including the role of horsepower in various aspects.)

- Petroleum Engineering: Drilling and Well Completions by S.P. C. and M.C. (This book provides a detailed analysis of drilling and well completion techniques, including the importance of horsepower in each phase.)

- Well Completion Design by E.B. and W.C. (This book focuses on the design and engineering of well completions, highlighting the essential role of horsepower in successful completions.)

Articles

- The Role of Horsepower in Drilling and Well Completion by (This article discusses the significance of horsepower in optimizing performance and efficiency in drilling and well completion.)

- Optimizing Horsepower for Enhanced Drilling Performance by (This article explores various techniques for maximizing horsepower utilization to improve drilling efficiency and minimize costs.)

- The Impact of Horsepower on Well Completion Costs by (This article examines the relationship between horsepower requirements and overall well completion costs, providing insights into cost optimization strategies.)

Online Resources

- Society of Petroleum Engineers (SPE): The SPE website offers a vast library of technical papers and articles related to drilling, well completion, and related engineering aspects. Search for "horsepower" or "power" to find relevant content.

- American Petroleum Institute (API): The API website provides standards and guidelines for the oil and gas industry, including specifications for drilling equipment and horsepower requirements.

- Oil & Gas Journal (OGJ): OGJ publishes industry news, technical articles, and research related to all aspects of oil and gas production, including drilling and well completion. Search their archives for articles on horsepower.

- World Oil: This journal offers articles and technical information on drilling, production, and related technologies, including insights on the role of horsepower in drilling and well completion.

Search Tips

- Use specific search terms like "horsepower drilling," "horsepower well completion," "drilling rig horsepower," etc.

- Combine terms with keywords like "efficiency," "optimization," "costs," "safety," and "performance."

- Use quotation marks to search for specific phrases like "horsepower requirements for fracking."

- Explore advanced search options to refine your search results by date, source, file type, etc.

Techniques

Horsepower in Drilling and Well Completion: A Deeper Dive

This expands on the provided text, breaking it down into chapters. Note that some sections will be brief due to the inherent limitations of the original text's scope. More detailed information would require significant additional research.

Chapter 1: Techniques for Optimizing Horsepower Utilization

This chapter focuses on practical methods for maximizing the efficiency and effectiveness of horsepower in drilling and well completion operations.

- Load Management: Efficient load management is crucial. This involves matching the horsepower supplied to the actual load demands of the equipment at any given moment. Overpowering leads to wasted energy; underpowering risks equipment failure. Real-time monitoring systems and advanced control algorithms are key tools.

- Power Transmission Optimization: Minimizing power losses during transmission is critical. This requires regular maintenance of belts, chains, gears, and hydraulic systems to ensure optimal efficiency. The selection of appropriate transmission components for the specific application is also vital.

- Drilling Parameter Optimization: Careful selection of drilling parameters (weight on bit, rotary speed, mud flow rate) can significantly impact the efficiency of horsepower usage. Advanced drilling automation systems can help optimize these parameters in real-time.

- Mud System Optimization: The properties of the drilling mud significantly influence the horsepower required. Optimizing mud rheology and minimizing friction losses can reduce the horsepower needed for drilling.

- Preventative Maintenance: Regular maintenance schedules for all horsepower-consuming equipment is essential to prevent unexpected downtime and maximize operational efficiency. This includes regular inspections, lubrication, and component replacements as needed.

Chapter 2: Models for Predicting and Managing Horsepower Requirements

This chapter explores the use of models to predict horsepower needs and manage its application effectively.

- Empirical Models: Simple models based on historical data and operational experience can estimate horsepower requirements for different drilling scenarios. These can be useful for initial planning.

- Simulation Models: More sophisticated simulation models, often using finite element analysis (FEA) or computational fluid dynamics (CFD), can provide a detailed prediction of horsepower demands under various conditions. These are particularly valuable for complex operations.

- Predictive Maintenance Models: Data-driven models can predict potential equipment failures based on operational parameters and historical data, allowing for proactive maintenance to prevent unexpected downtime related to horsepower loss.

Chapter 3: Software and Technology for Horsepower Monitoring and Control

This chapter examines the software and technologies used to monitor and manage horsepower in drilling and well completion.

- Drilling Automation Systems: These systems use sensors and control algorithms to optimize drilling parameters in real-time, maximizing the use of available horsepower.

- Real-Time Monitoring Systems: These systems continuously monitor the power consumption of various equipment components, allowing for early detection of anomalies and potential problems.

- Data Acquisition and Analysis Software: Specialized software packages are used to collect, analyze, and visualize data on horsepower consumption, enabling better understanding of operational efficiency and identifying areas for improvement.

- Predictive Maintenance Software: Software capable of predicting equipment failures based on operational data can minimize unscheduled downtime and optimize horsepower utilization.

Chapter 4: Best Practices for Horsepower Management in Drilling and Well Completion

This chapter outlines best practices to ensure safe and efficient use of horsepower.

- Regular Training and Competency Assessment: Personnel must be adequately trained in the safe operation and maintenance of high-powered equipment.

- Strict Adherence to Safety Regulations: All operations should comply with relevant safety regulations and standards to prevent accidents and injuries.

- Effective Communication and Coordination: Clear communication and coordination between different teams are essential to ensure safe and efficient operations.

- Proactive Maintenance Strategy: Implementing a proactive maintenance strategy, focusing on preventative measures, is key to minimizing downtime.

- Continuous Improvement Initiatives: Regular review of operations and implementation of continuous improvement initiatives can further optimize horsepower usage.

Chapter 5: Case Studies of Horsepower Optimization in Drilling and Well Completion

This chapter would showcase real-world examples of successful horsepower optimization projects. (Due to the lack of specific data in the original text, this section cannot be fully fleshed out here. Real-world case studies would require independent research.) Examples could include:

- A case study illustrating how improved mud system design reduced horsepower requirements, leading to cost savings and reduced environmental impact.

- A case study demonstrating the effectiveness of predictive maintenance in preventing costly downtime associated with power equipment failures.

- A case study showing how real-time monitoring systems improved the efficiency of a drilling operation by optimizing drilling parameters.

This expanded structure provides a more comprehensive overview of horsepower's critical role in drilling and well completion. Remember that each chapter would require significant expansion with detailed information and specific examples.

- طلب تبرير المصروفات طلب مبرر الإنفاق: د… تخطيط وجدولة المشروع

- التكلفة الميزانية للعمل المجدول فهم تكلفة العمل الم… تقدير التكلفة والتحكم فيها

- حدود البطارية فهم حدود البطارية ف… المصطلحات الفنية العامة

- أداة الصمام السفلي أداة الصمام السفلي:… الحفر واستكمال الآبار

- جدول المحتويات TOC: فهم قمة الإسمن… المصطلحات الفنية العامة

Comments